不同气氛热冲击下Al:WS2薄膜摩擦学性能的响应机理

doi: 10.11728/cjss2023.05.2022-0037 cstr: 32142.14.cjss2023.05.2022-0037

Response Mechanism of Tribological Properties of Al:WS2 Film under Different Ambient Thermal Shock

-

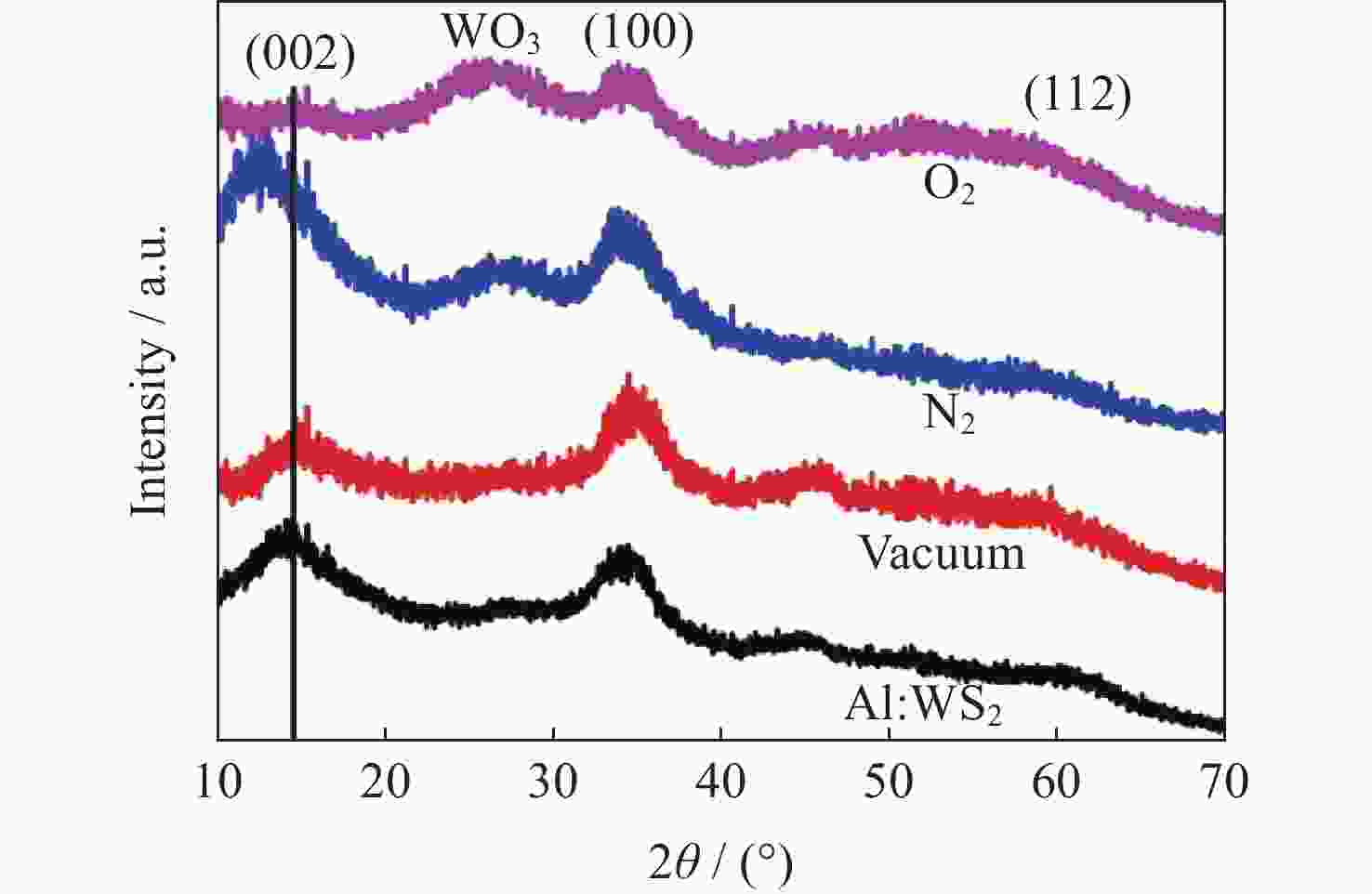

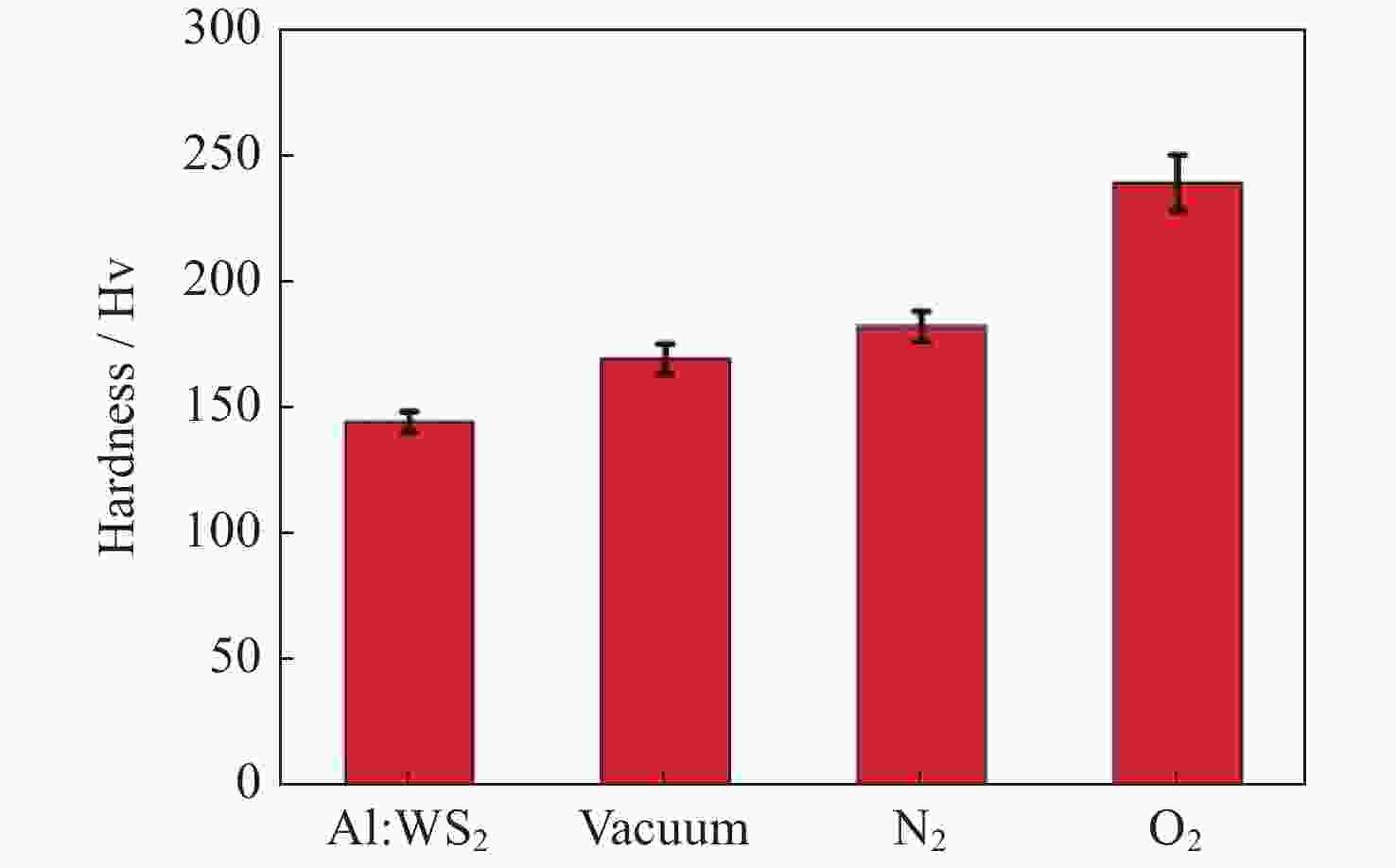

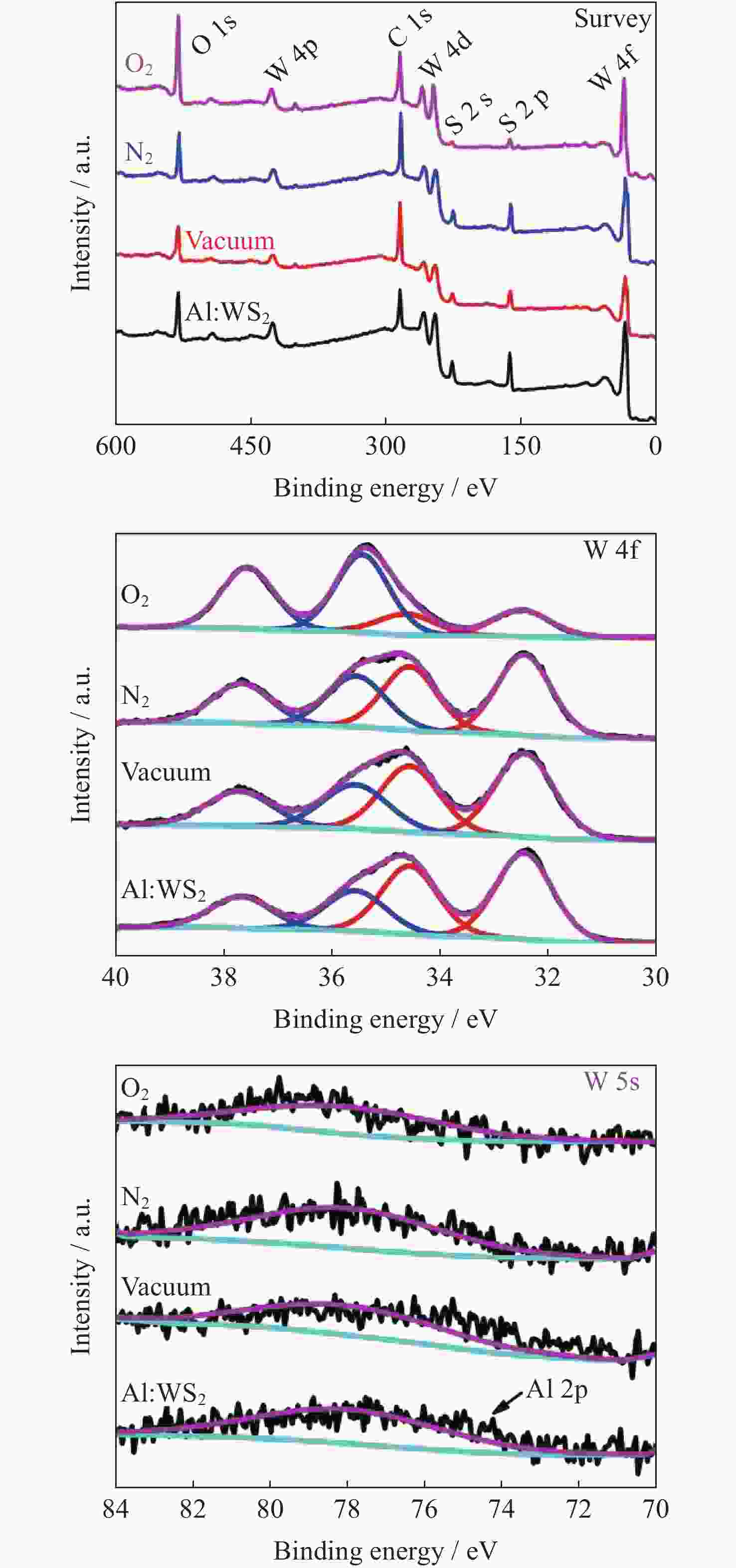

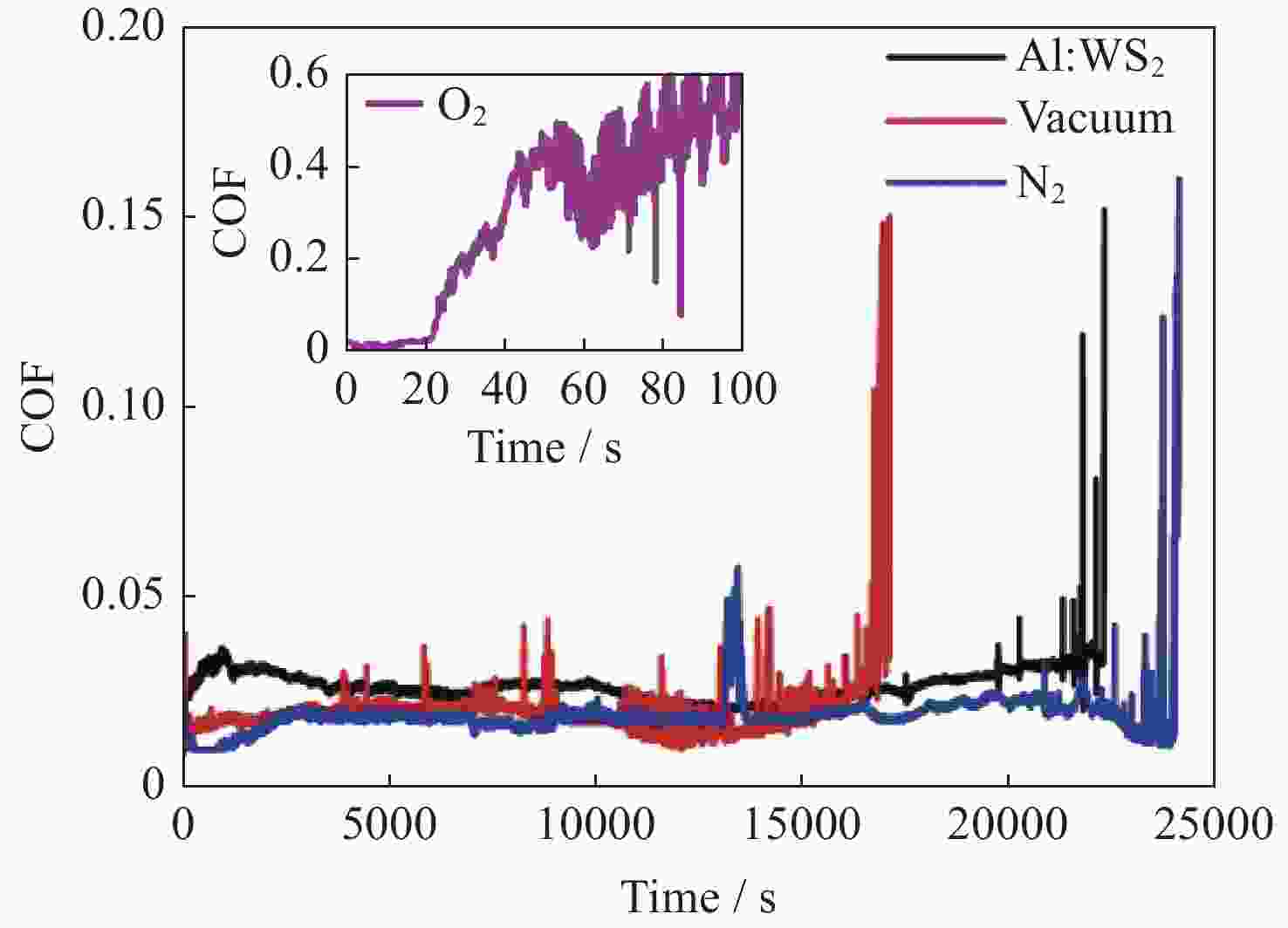

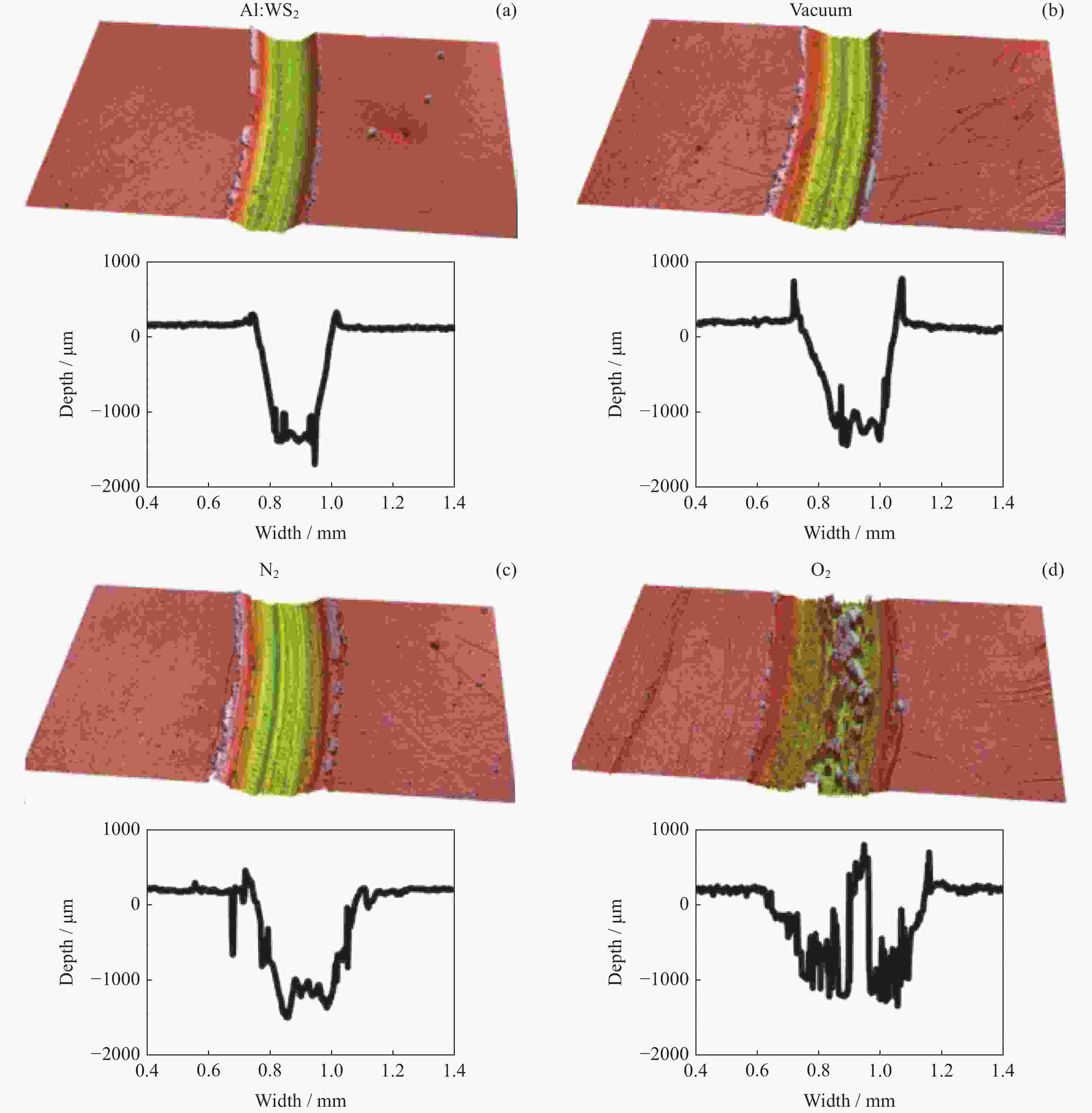

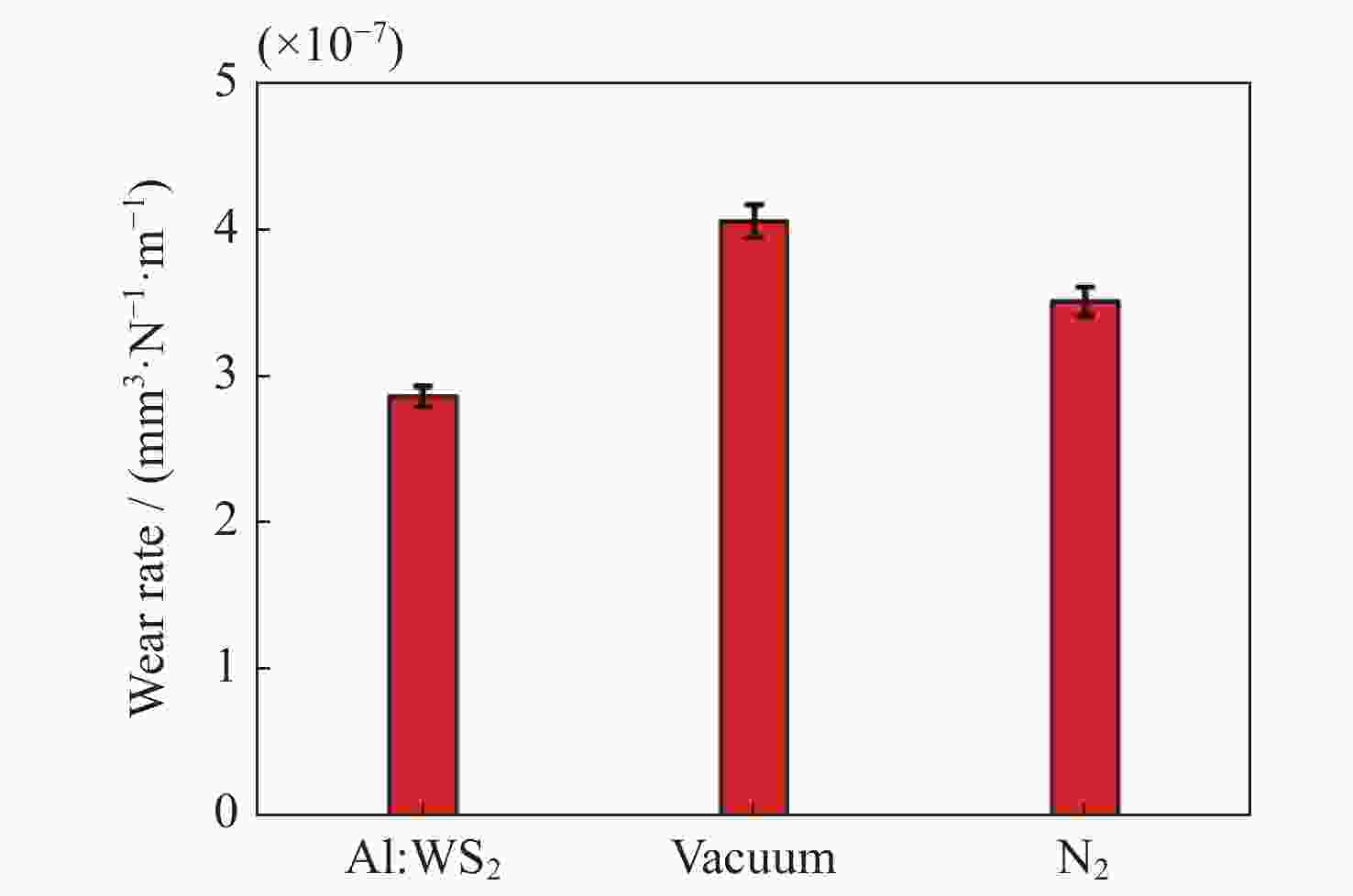

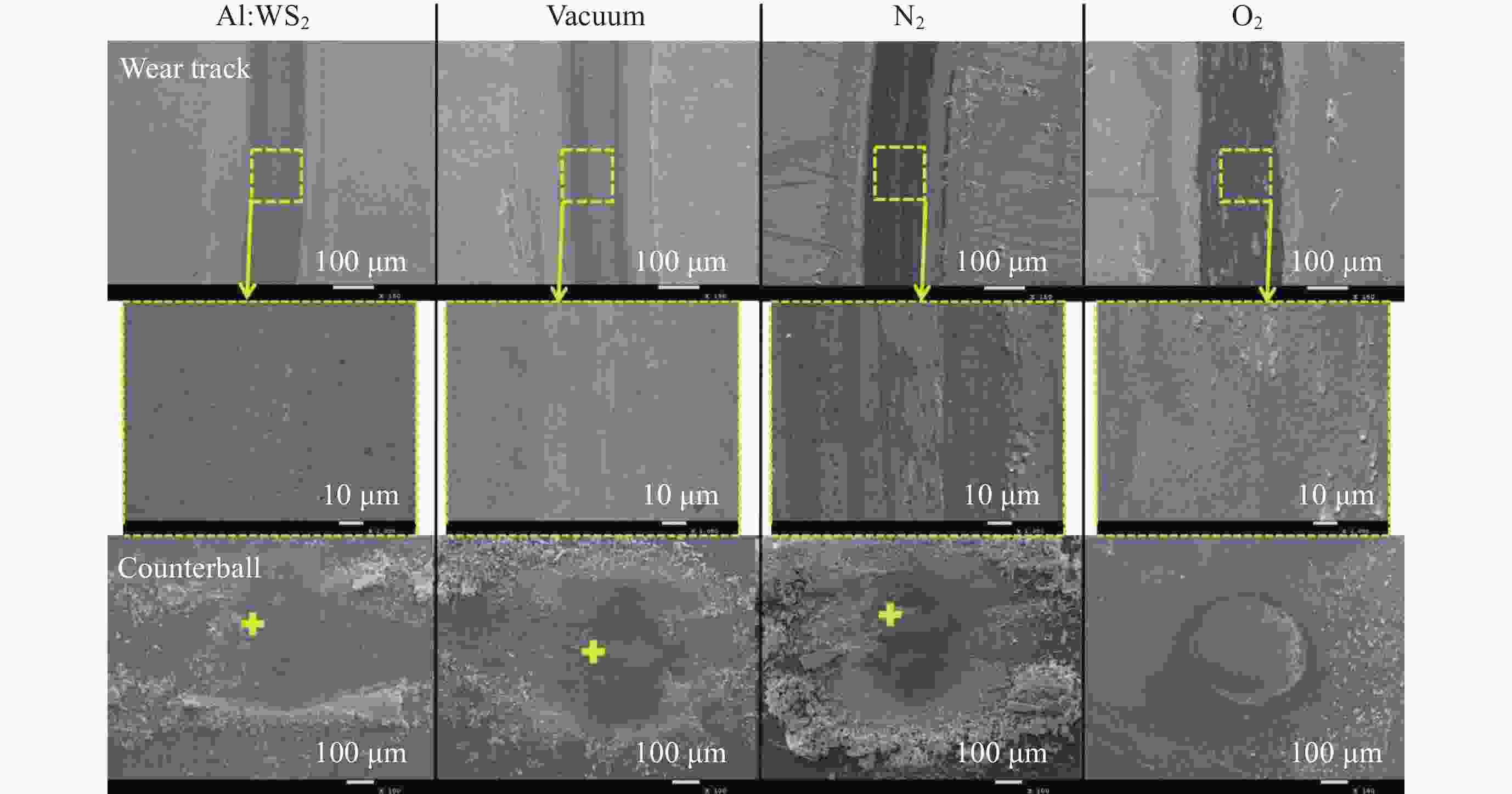

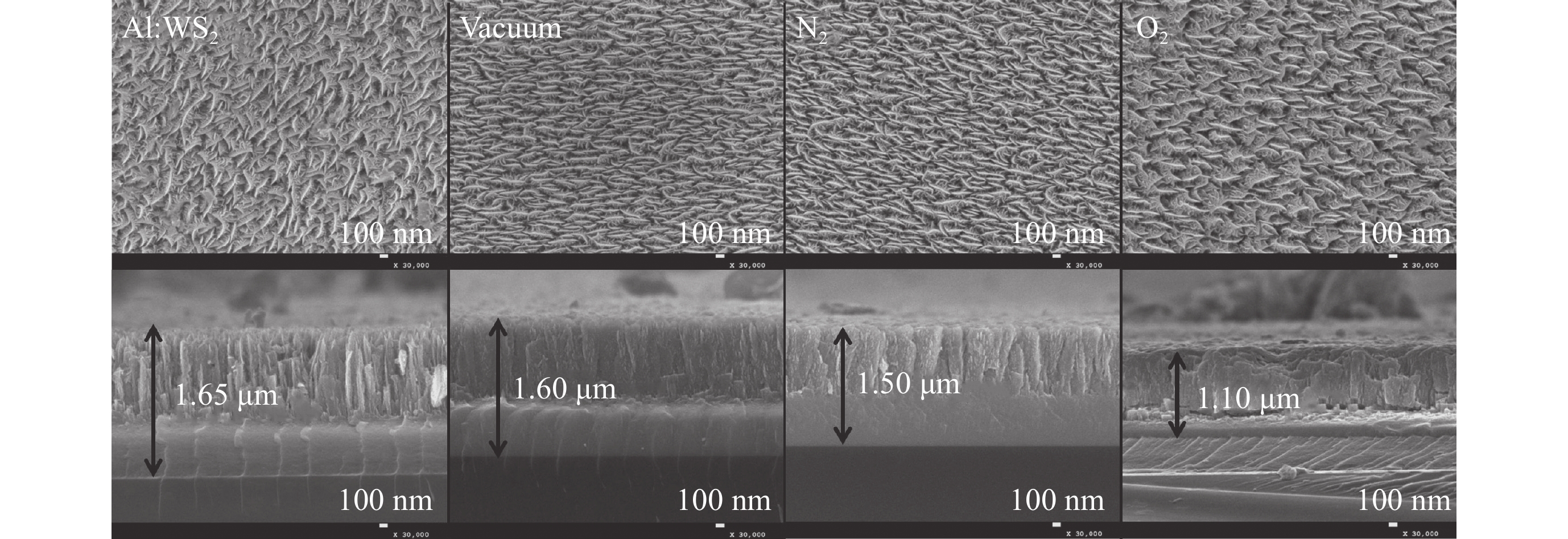

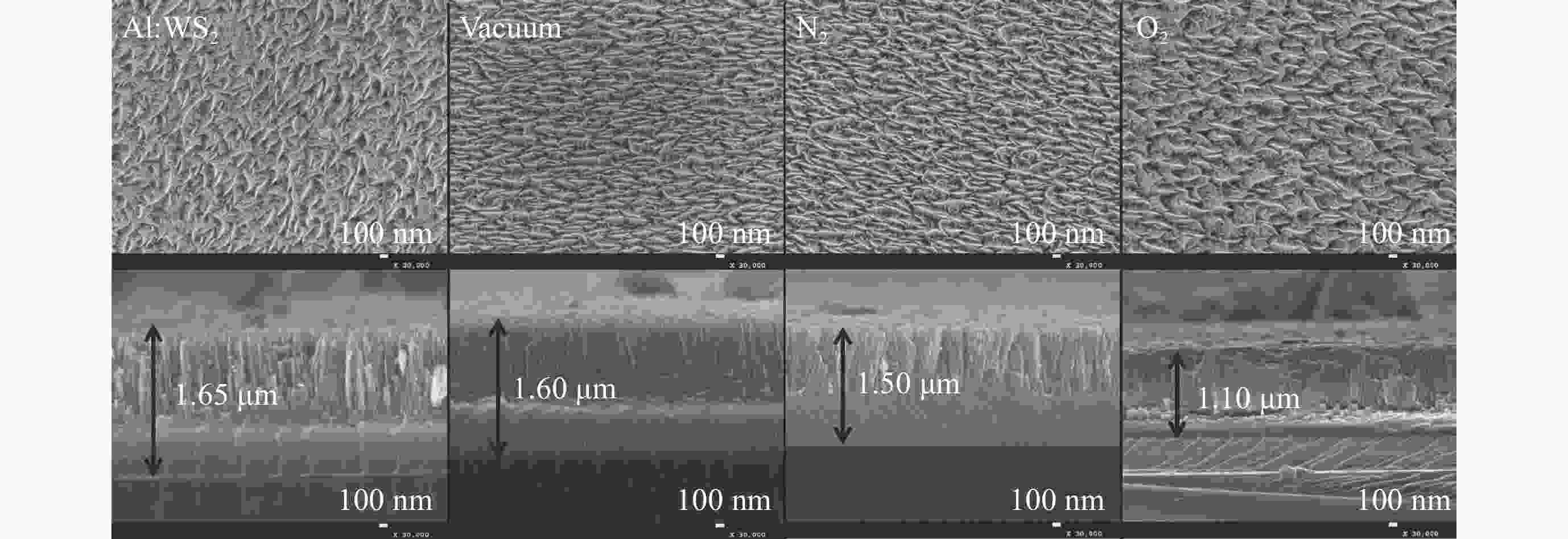

摘要: 采用磁控溅射技术制备了Al:WS2薄膜。为考查不同气氛热冲击下Al:WS2薄膜摩擦学性能的响应机理,采用自行研制的温度交变真空摩擦试验机开展了真空、氮气及氧气气氛的–100~+250℃的热冲击试验,并对热冲击后Al:WS2薄膜结构、成分以及摩擦学性能进行了研究。研究发现,热冲击后,Al:WS2薄膜柱状晶长大,S含量减少,部分WS2被氧化为WO3,薄膜硬度增加。经氮气热冲击后,薄膜的(002)衍射峰强度明显增强,使得摩擦系数降低。经真空热冲击后,在薄膜表面形成的WO3起到磨粒磨损作用,减少了薄膜寿命;经氧气热冲击后,Al:WS2薄膜中大量起润滑作用的WS2被氧化为WO3,薄膜的寿命显著缩短。Abstract: Al:WS2 films were prepared by magnetron sputtering technology. In order to investigate the response mechanism of the tribological properties of Al:WS2 film under different ambient thermal shock, the thermal shock tests of –100~+250℃ in vacuum, nitrogen and oxygen were carried out using the temperature altering vacuum tribometer developed, and the structure, composition and tribological properties of Al:WS2 films after thermal shock were mainly studied. It was found that the columnar crystal of Al:WS2 film grows, S content decreases, part of WS2 is oxidized to WO3, and the hardness of film increases after thermal shock. After thermal shock under nitrogen atmosphere, the intensity of (002) diffraction peak of Al:WS2 film is obviously enhanced, and the friction coefficient decreased. After thermal shock with vacuum, WO3 appears on the surface of Al:WS2 film plays the role of abrasive wear, which reduces the life of film. After oxygen thermal shock, a large number of WS2 is oxidized to WO3, and the wear life of the film is significantly shortened due to the serious abrasive wear.

-

Key words:

- Al:WS2 film /

- Thermal shock /

- Atmosphere /

- Friction

-

表 1 磁控溅射沉积Al:WS2薄膜的工艺参数

Table 1. Deposition parameter of Al:WS2 film by magnetron sputtering system

Deposition parameters Values WS2 target power/W 600 Al target current/A 0.15 Working pressure/Pa 6.0×10–3 Bias voltage/V –20 Ar flow/(mL·min–1) 70 Substrate rotation speed/(r·min–1) 1 Deposition time/min 150 表 2 由XPS计算得到的未处理及不同气氛热冲击后Al:WS2薄膜的相对元素含量(原子百分数)

Table 2. Calculated element content (atom percent) of untreated and thermal shocked Al:WS2 films

Specimen W S Al C O Al:WS2 12.43 19.71 0.92 44.54 22.40 Vacuum 7.73 9.85 1.31 61.86 19.25 N2 10.42 13.51 0.53 54.54 21.00 O2 9.43 4.85 0 49.88 35.84 表 3 未处理及不同气氛热冲击后Al:WS2薄膜的 W 4f XPS拟合数据

Table 3. Fitted W 4f XPS data of untreated and thermal shocked Al:WS2 films

Specimen W 4f WS2 (atom percent) WO3 (atom percent) Al:WS2 66.72 33.28 Vacuum 62.91 37.09 N2 59.56 40.44 O2 27.14 72.86 表 4 未处理及不同气氛热冲击后Al:WS2薄膜的磨斑转移膜EDS元素成分分析(原子百分数)

Table 4. Element content (atom percent) from EDS analysis of transfer films on wear scars of untreated and thermal shocked Al:WS2 films

Specimen Al W S C O Fe Al:WS2 0.2 6.3 5.9 5.5 15.4 66.6 Vacuum 0.1 0.9 0.3 5.0 10.4 83.3 N2 0.2 21.1 19.0 8.0 24.6 27.0 -

[1] JOST H P. Tribology-origin and future[J]. Wear, 1990, 136(1): 1-17 doi: 10.1016/0043-1648(90)90068-L [2] MATSUMOTO K, TAGAWA M, AKIYAMA M. Tribological characteristics of bonded MoS2 film exposed to AO, UV and real LEO environment in SM/SEED experiment[J]. AIP Conference Proceedings, 2009, 1087(1): 148-153 [3] VAZIRISERESHK M R, MARTINI A, STRUBBE D A, et al. Solid lubrication with MoS2: a review[J]. Lubricants, 2019, 7(7): 57 doi: 10.3390/lubricants7070057 [4] CAI M R, YU Q L, LIU W M, et al. Ionic liquid lubricants: when chemistry meets tribology[J]. Chemical Society Reviews, 2020, 49(21): 7753-7818 doi: 10.1039/D0CS00126K [5] SERLES P, GABER K, PAJOVIC S, et al. High temperature microtribological studies of MoS2 lubrication for low earth orbit[J]. Lubricants, 2020, 8(4): 49 doi: 10.3390/lubricants8040049 [6] 高晓明, 胡明, 孙嘉奕, 等. 润滑材料的空间环境效应[J]. 中国材料进展, 2017, 36(7/8): 481-491 doi: 10.7502/j.issn.1674-3962.2017.07.01GAO Xiaoming, HU Ming, SUN Jiayi, et al. Space environment effects on lubricants[J]. Materials China, 2017, 36(7/8): 481-491 doi: 10.7502/j.issn.1674-3962.2017.07.01 [7] 钟爱文, 姚萍屏, 肖叶龙, 等. 空间摩擦学及其材料的研究进展[J]. 航空材料学报, 2017, 37(2): 88-99 doi: 10.11868/j.issn.1005-5053.2015.000195ZHANG Aiwen, YAO Pingping, XIAO Yelong, et al. Research status and developing trend of space tribology and tribological materials[J]. Journal of Aeronautical Materials, 2017, 37(2): 88-99 doi: 10.11868/j.issn.1005-5053.2015.000195 [8] YANG J, WANG D S, FU Y L, et al. Improving the tribological and anti-corrosion property of the WS2 film through Ta doping[J]. Vacuum, 2021, 192: 110485 doi: 10.1016/j.vacuum.2021.110485 [9] FAN X, SHI Y B, CUI M J, et al. MoS2/WS2 nanosheet-based composite films irradiated by atomic oxygen: implications for lubrication in space[J]. ACS Applied Nano Materials, 2021, 4(10): 10307-10320 doi: 10.1021/acsanm.1c01816 [10] MARIAN M, BERMAN D, ROTA A, et al. Layered 2 D nanomaterials to tailor friction and wear in machine elements—a review[J]. Advanced Materials Interfaces, 2022, 9(3): 2101622 doi: 10.1002/admi.202101622 [11] YAN Z, SUI X D, YAN M M, et al. Dependence of friction and wear on the microstructures of WS2 films under a simulated space environment[J]. ACS Applied Materials & Interfaces, 2020, 12(50): 56632-56641 [12] FU Y L, JIANG D, WANG D S, et al. Tribological performance of MoS2–WS2 composite film under the atomic oxygen irradiation conditions[J]. Materials, 2020, 13(6): 1407 doi: 10.3390/ma13061407 [13] LINCE J R. Effective application of solid lubricants in spacecraft mechanisms[J]. Lubricants, 2020, 8(7): 74 doi: 10.3390/lubricants8070074 [14] XU S S, GAO X M, HU M, et al. Dependence of atomic oxygen resistance and the tribological properties on microstructures of WS2 films[J]. Applied Surface Science, 2014, 298: 36-43 doi: 10.1016/j.apsusc.2014.01.002 [15] GAO X M, FU Y L, JIANG D, et al. Structural, mechanical, and tribological properties of WS2-Al nanocomposite film for space application[J]. Tribology Letters, 2018, 66(4): 137 doi: 10.1007/s11249-018-1085-z [16] ZHANG R, CUI Q F, WENG L J, et al. Modification of structure and wear resistance of closed-field unbalanced-magnetron sputtered MoS2 film by vacuum-heat-treatment[J]. Surface and Coatings Technology, 2020, 401: 126215 doi: 10.1016/j.surfcoat.2020.126215 [17] 董春萌, 高晓明, 余兵, 等. 水浴对MoS2薄膜结构及摩擦学性能影响的研究[J]. 摩擦学学报, 2020, 40(2): 166-174DONG Chunmeng, GAO Xiaoming, YU Bing, et al. Structure and tribological behaviors of MoS2 films treated by water bath[J]. Tribology, 2020, 40(2): 166-174 [18] LIU J, SUI X D, YAN Z, et al. Cr doped MoS2 films: tribological properties, microstructure, and electronic structure[J]. Journal of Tribology, 2021, 143(9): 091401 doi: 10.1115/1.4050141 [19] DING X Z, ZENG X T, HE X Y, et al. Tribological properties of Cr- and Ti-doped MoS2 composite coatings under different humidity atmosphere[J]. Surface and Coatings Technology, 2010, 205(1): 224-231 doi: 10.1016/j.surfcoat.2010.06.041 [20] XU S S, GAO X M, SUN J Y, et al. Comparative study of moisture corrosion to WS2 and WS2/Cu multilayer films[J]. Surface and Coatings Technology, 2014, 247: 30-38 doi: 10.1016/j.surfcoat.2014.03.001 [21] CAI H C, XUE Y J, LI H, et al. Friction and wear behavior of self-lubricating La-Ti/WS2 films by unbalanced magnetron sputtering[J]. Rare Metal Materials and Engineering, 2021, 50(8): 2708-2714 [22] LIU J, YAN Z, HAO J Y, et al. Two strategies to improve the lubricating performance of WS2 film for space application[J]. Tribology International, 2022, 175: 107825 doi: 10.1016/j.triboint.2022.107825 [23] NEVSHUPA R A, DE SEGOVIA J L, ROMAN E. Surface-induced reactions of absorbed hydrogen under mutual mechanical forces[J]. Vacuum, 2005, 80(1/2/3): 241-246 -

-

下载:

下载: