微重力条件下PCM液桥内固液相变过程及热毛细对流数值模拟

doi: 10.11728/cjss2024.03.2023-0105 cstr: 32142.14.cjss2024.03.2023-0105

Evolution Mechanism of Phase Change Materials Liquid-bridge Phase Transition and Thermocapillary Convection under Microgravity Conditions

-

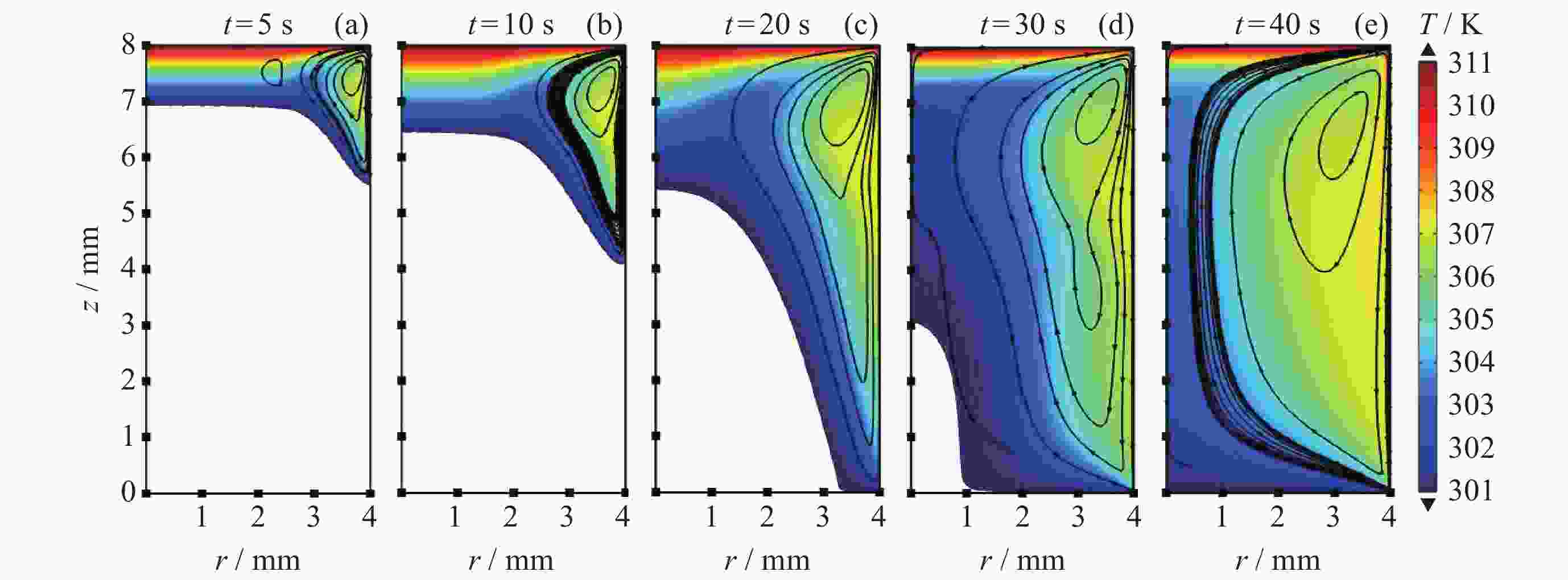

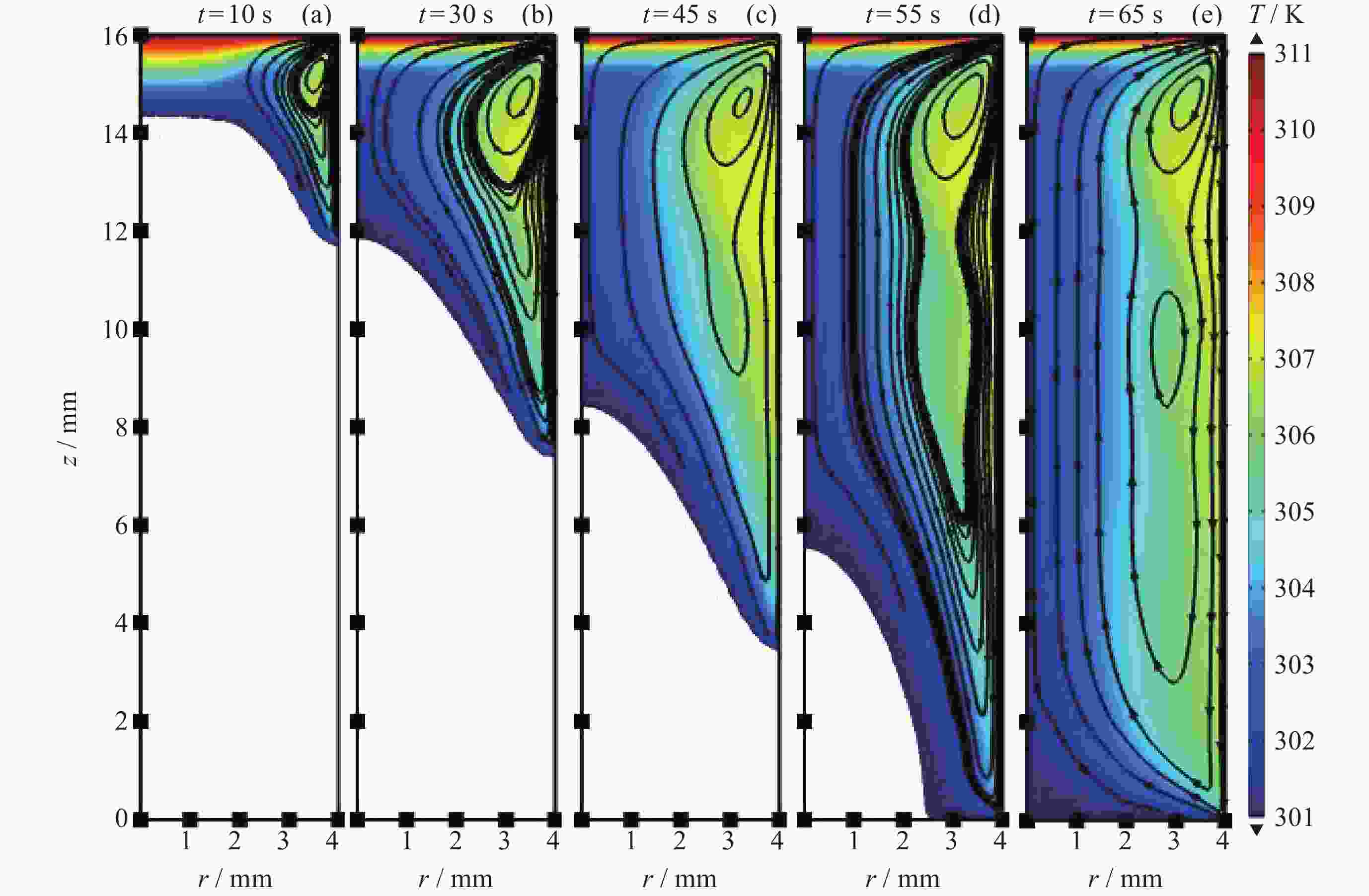

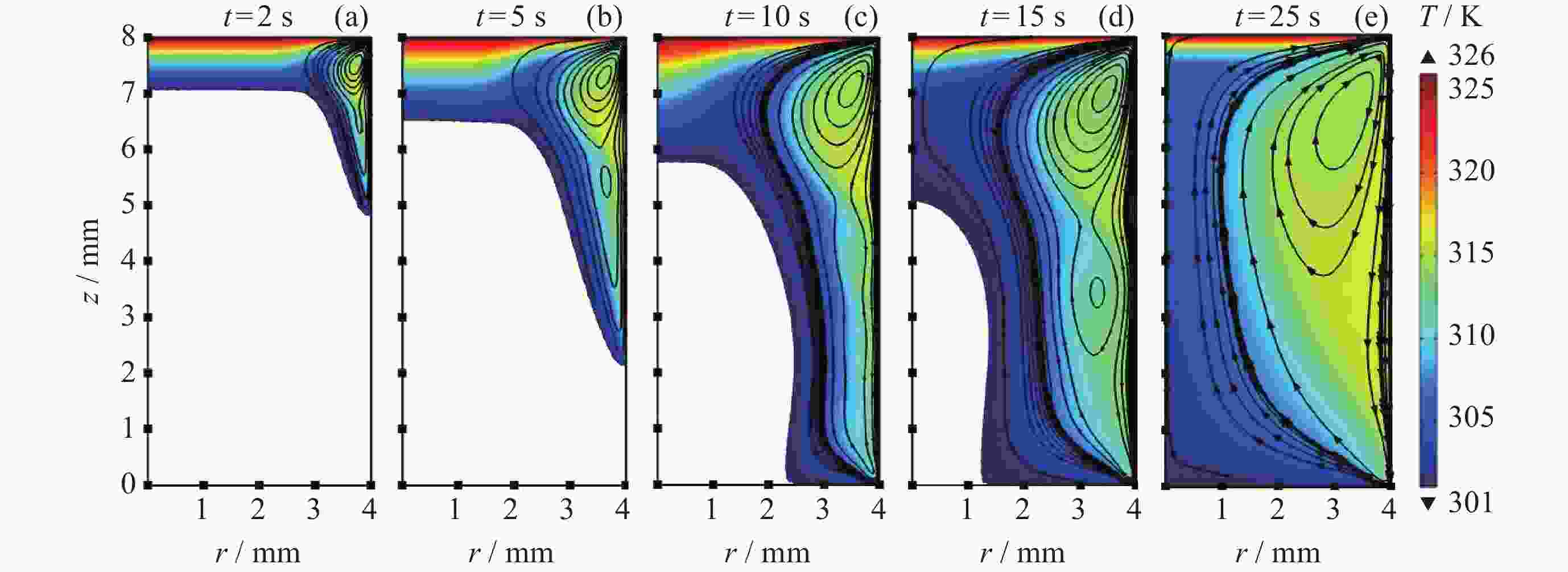

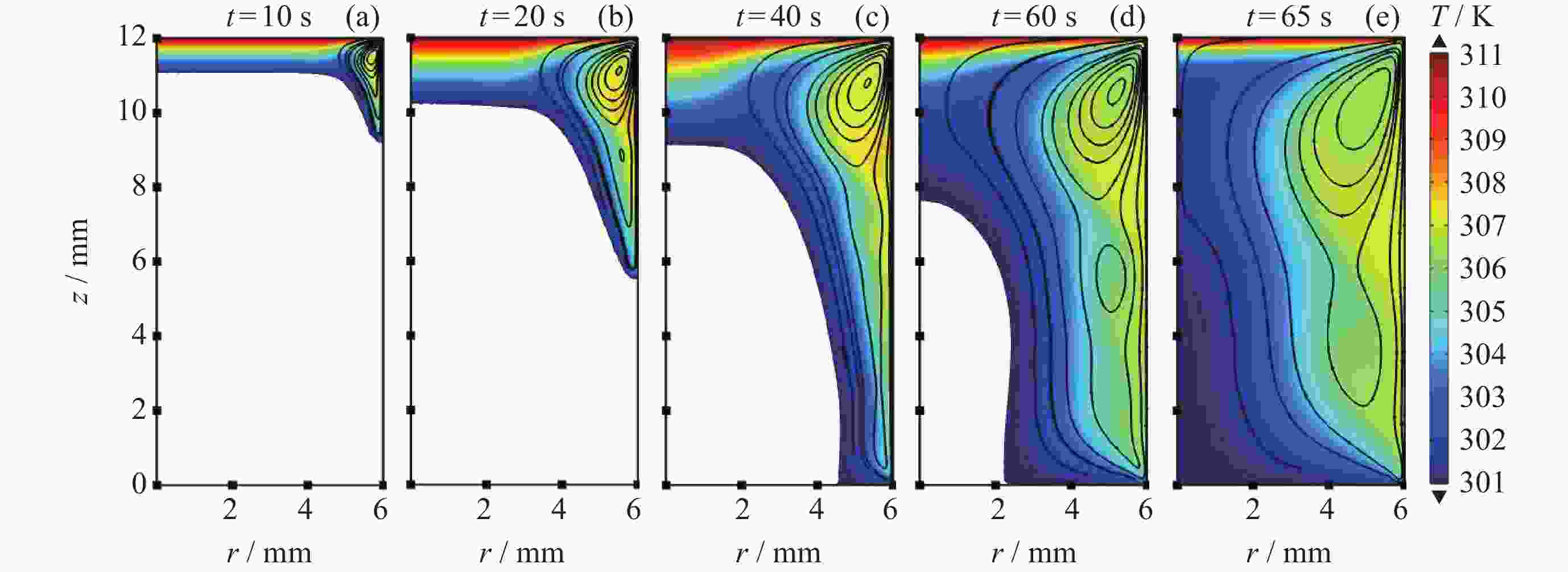

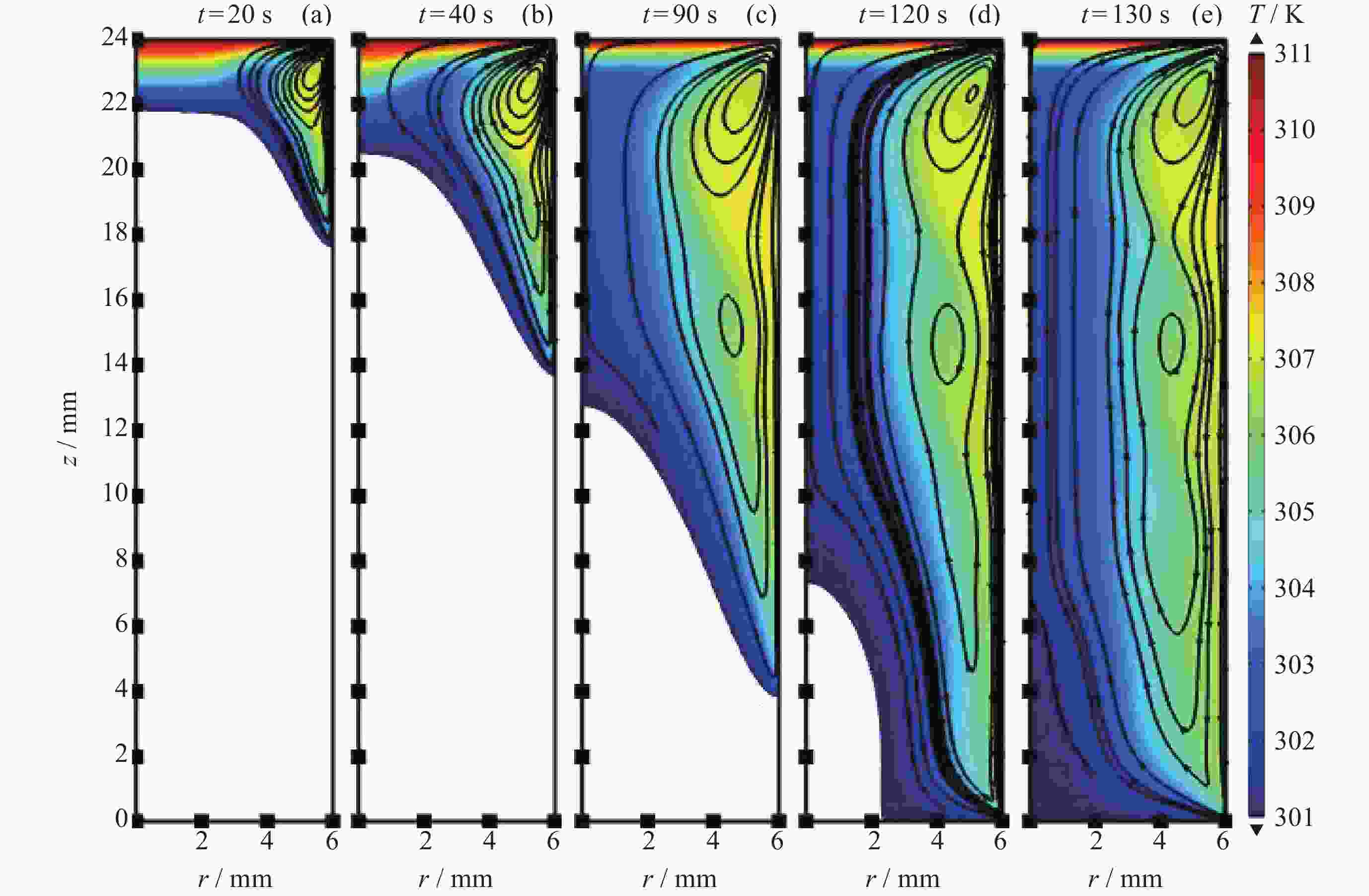

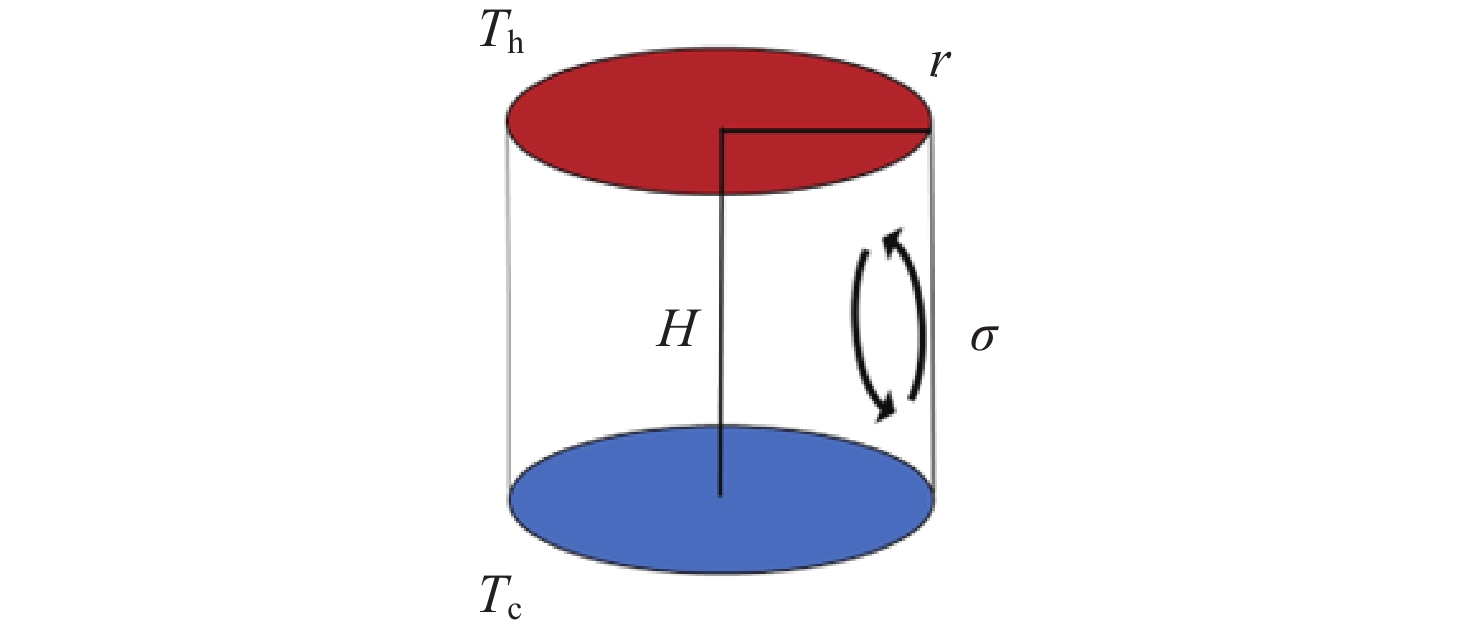

摘要: 为揭示微重力条件下PCM液桥相变过程流动特征及相变演化规律, 建立PCM液桥数理模型, 采用数值模拟的方法系统研究了不同工况下PCM液桥相变过程中固液界面的演化过程, 分析不同高径比和温差对液桥形状、固液界面演化规律、相变速度和热毛细流动的影响. 研究结果显示, 在大温差条件下热毛细流动更加强烈, 处于外部壁面处的相变材料的相变速度也会更快, 外壁处的相变界面与壁面的夹角会更小. 大高径比条件下会有同样的效果, 同时也会产生更多的涡胞结构, 热毛细对流效果更明显. 结果表明, 微重力条件下通过流体界面热毛细效应强化PCM相变是一种有效的方法.Abstract: In order to reveal the flow characteristics and evolution law of PCM liquid-bridge phase transition under microgravity conditions, the evolution process of solid-liquid interface during PCM liquid-bridge phase transition under different working conditions was numerically studied based on numerical simulation method. The effects of different height-diameter ratio and temperature difference on the shape of liquid bridge, the evolution law of solid-liquid interface, phase transition velocity and thermal capillary flow were analyzed. The results show that under the condition of large temperature difference, the thermal capillary flow is more intense, the phase transition speed of the phase change material at the outer wall is faster, and the angle between the phase change interface at the outer wall and the wall is smaller. Under the condition of large aspect ratio, the same effect will be achieved, and more vortex cell structures will be generated, and the thermal capillary convection effect is more obvious. The results show that strengthening PCM phase transition through fluid interface thermal capillary effect under microgravity conditions is an effective method.

-

Key words:

- Liquid bridge /

- Phase change material /

- Thermocapillary convection /

- Phase change /

- Interface /

- Flow

-

表 1 相变材料热物性 (T=298 K, P=1.01×105 Pa)

Table 1. Thermal properties of phase change material (T=298 K, P=1.01×105 Pa)

热物性参数 正十八烷 固相密度ρs/(kg·m–3) 865 固相比热容Cps/(J·kg–1·K–1) 1934 固相导热系数λs/(W·m–1·K–1) 0.358 液相密度ρl/(kg·m–3) 780 液相比热容Cpl/(J·kg–1·K–1) 2196 液相导热系数λl/(W·m–1·K–1) 0.148 动力黏度μ/(Pa·s) 0.00354 潜热Cl/(kJ·kg–1) 243.5 表面张力温度系数γT/(N·m–1·K–1) 8.44×10–5 熔点Tm/K 301 表 2 不同网格数下液相的最大流速

Table 2. Maximum flow rate of the liquid phase at different grid numbers

网格数 最大流速/(m·s–1) 1036 0.00637 2618 0.00645 6498 0.00647 14448 0.00649 -

[1] YOU M, ZHANG X X, LI W, et al. Effects of MicroPCMs on the fabrication of MicroPCMs/polyurethane composite foams[J]. Thermochimica Acta, 2008, 472(1/2): 20-24 [2] HASNAIN S M. Review on sustainable thermal energy storage technologies, Part I: heat storage materials and techniques[J]. Energy Conversion and Management, 1998, 39(11): 1127-1138 doi: 10.1016/S0196-8904(98)00025-9 [3] LANE G A, SHAMSUNDAR N. Solar heat storage: latent heat materials, Vol. I: background and scientific principles[J]. Journal of Solar Energy Engineering, 1983, 105(4): 467 [4] SÁNCHEZ P S, EZQUERRO J M, FERNÁNDEZ J, et al. Thermocapillary effects during the melting of phase-change materials in microgravity: steady and oscillatory flow regimes[J]. Journal of Fluid Mechanics, 2021, 908: A20 doi: 10.1017/jfm.2020.852 [5] 李杰, 杨志刚, 毛科, 等. 微重力下单晶硅生长中热毛细对流的控制研究[J]. 重庆大学学报(自然科学版), 2002, 25(3): 97-100LI Jie, YANG Zhigang, MAO Ke, et al. Study on the reduction of thermocapillary convection of the single-crystal growth of silicon under microgravity[J]. Journal of Chongqing University (Natural Science Edition), 2002, 25(3): 97-100 [6] MADRUGA S, MENDOZA C. Enhancement of heat transfer rate on phase change materials with thermocapillary flows[J]. The European Physical Journal Special Topics, 2017, 226(6): 1169-1176 doi: 10.1140/epjst/e2016-60207-7 [7] MADRUGA S, MENDOZA C. Heat transfer performance and melting dynamic of a phase change material subjected to thermocapillary effects[J]. International Journal of Heat and Mass Transfer, 2017, 109: 501-510 doi: 10.1016/j.ijheatmasstransfer.2017.02.025 [8] EZQUERRO J M, BELLO A, SÁNCHEZ P S, et al. The thermocapillary effects in phase change materials in microgravity experiment: design, preparation and execution of a parabolic flight experiment[J]. Acta Astronautica, 2019, 162: 185-196 doi: 10.1016/j.actaastro.2019.06.004 [9] EZQUERRO J M, SÁNCHEZ P S, BELLO A, et al. Experimental evidence of thermocapillarity in phase change materials in microgravity: measuring the effect of Marangoni convection in solid/liquid phase transitions[J]. International Communications in Heat and Mass Transfer, 2020, 113: 104529 doi: 10.1016/j.icheatmasstransfer.2020.104529 [10] DUAN Li, WANG Jia, KANG Qi. Research on Space and Ground Experiments of Liquid Bridge Thermocapillary Convection [C]//Summary of Papers at the 9th National Conference on Fluid Mechanics Nanjing: Fluid Mechanics Professional Committee of the Chinese Society of Mechanics, 2016 (段俐, 王佳, 康琦. 液桥热毛细对流空间和地面实验研究[C]//第九届全国流体力学学术会议论文摘要集. 南京: 中国力学学会流体力学专业委员会, 2016 [11] 张迪, 段俐, 康琦. 实践十号卫星项目——热毛细对流振荡特征的地面研究[J]. 力学与实践, 2016, 38(1): 43-48 doi: 10.6052/1000-0879-15-315ZHANG Di, DUAN Li, KANG Qi. SJ-10 satellite project—ground research of oscillations characteristics of thermocapillary convection[J]. Mechanics in Engineering, 2016, 38(1): 43-48 doi: 10.6052/1000-0879-15-315 [12] SÁNCHEZ P S, EZQUERRO J M, FERNÁNDEZ J, et al. Thermocapillary effects during the melting of phase change materials in microgravity: heat transport enhancement[J]. International Journal of Heat and Mass Transfer, 2020, 163: 120478 doi: 10.1016/j.ijheatmasstransfer.2020.120478 [13] SLOBOZHANIN L A, PERALES J M. Stability of liquid bridges between equal disks in an axial gravity field[J]. Physics of Fluids A: Fluid Dynamics, 1993, 5(6): 1305-1314 doi: 10.1063/1.858567 [14] SALGADO SÁNCHEZ P, EZQUERRO J M, PORTER J, et al. Effect of thermocapillary convection on the melting of phase change materials in microgravity: experiments and simulations[J]. International Journal of Heat and Mass Transfer, 2020, 154: 119717 doi: 10.1016/j.ijheatmasstransfer.2020.119717 [15] CHERNATINSKY V I, BIRIKH R V, BRISKMAN V A, et al. Thermocapillary flows in long liquid bridges under microgravity[J]. Advances in Space Research, 2002, 29(4): 619-624 doi: 10.1016/S0273-1177(01)00652-4 -

-

张永春 男, 1982年3月出生于江苏省苏州市, 现为江苏省特种设备安全监督检验研究院(无锡分院)职员, 高级工程师, 主要研究方向为锅炉运行优化及节能减排技术等. E-mail:

张永春 男, 1982年3月出生于江苏省苏州市, 现为江苏省特种设备安全监督检验研究院(无锡分院)职员, 高级工程师, 主要研究方向为锅炉运行优化及节能减排技术等. E-mail:

下载:

下载: