Numerical Simulation of Interfacial Oscillation Inside a Micro-pin-finned Structure

-

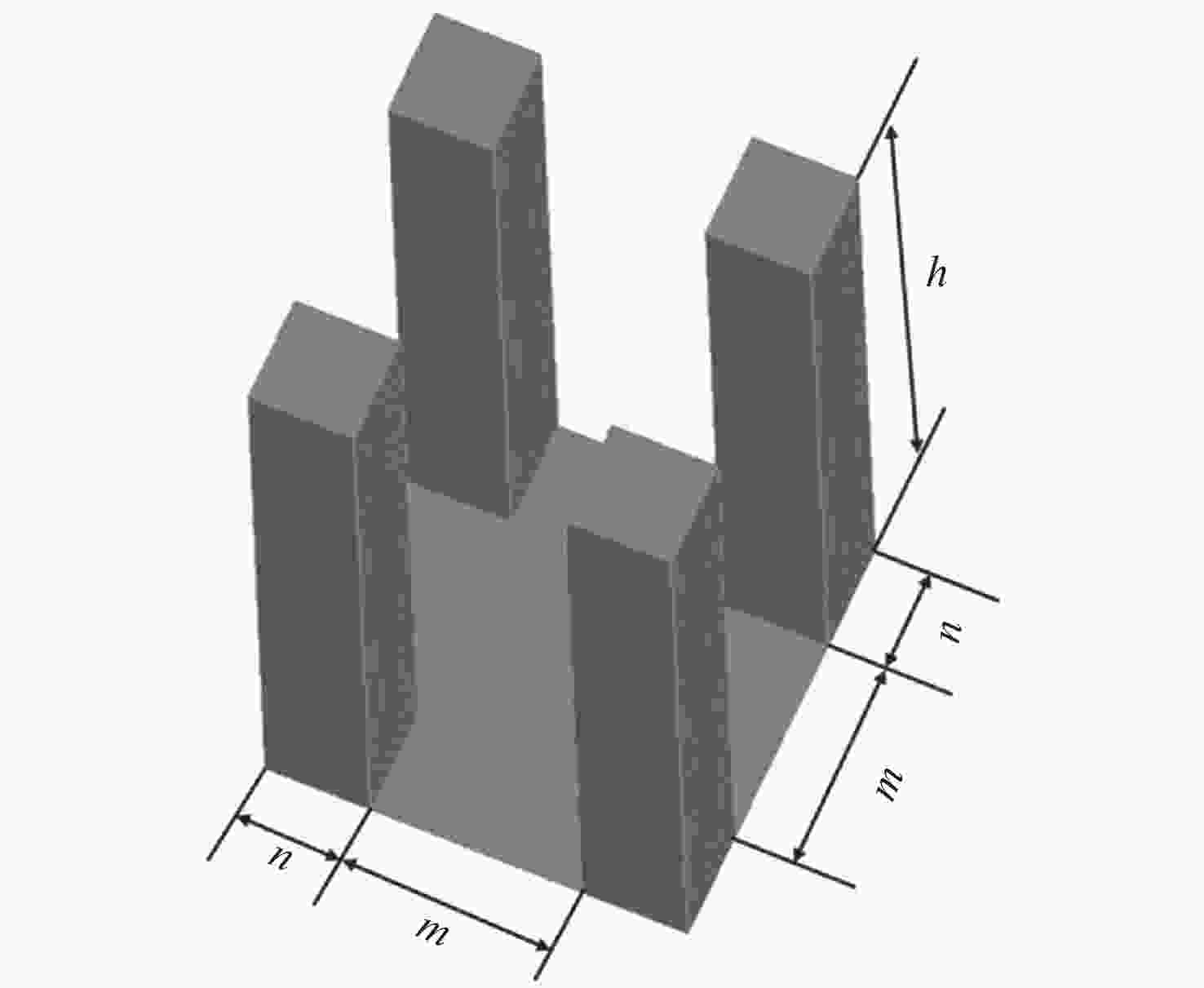

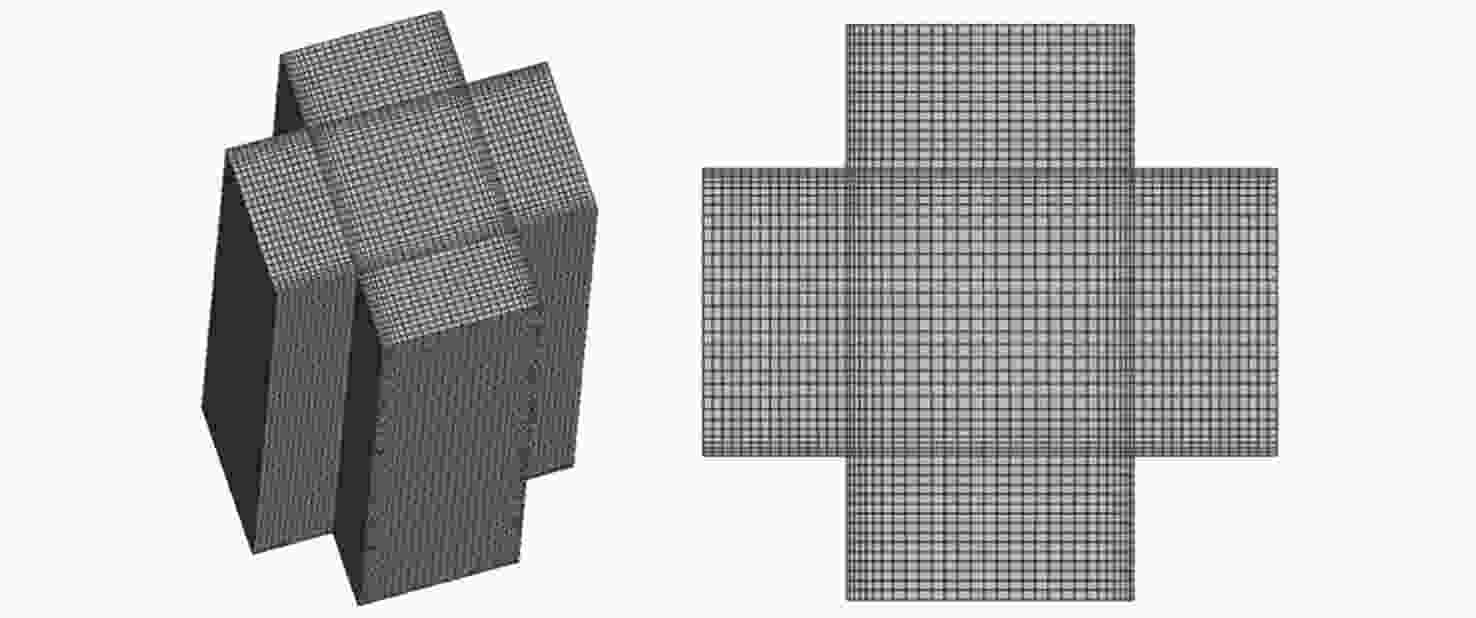

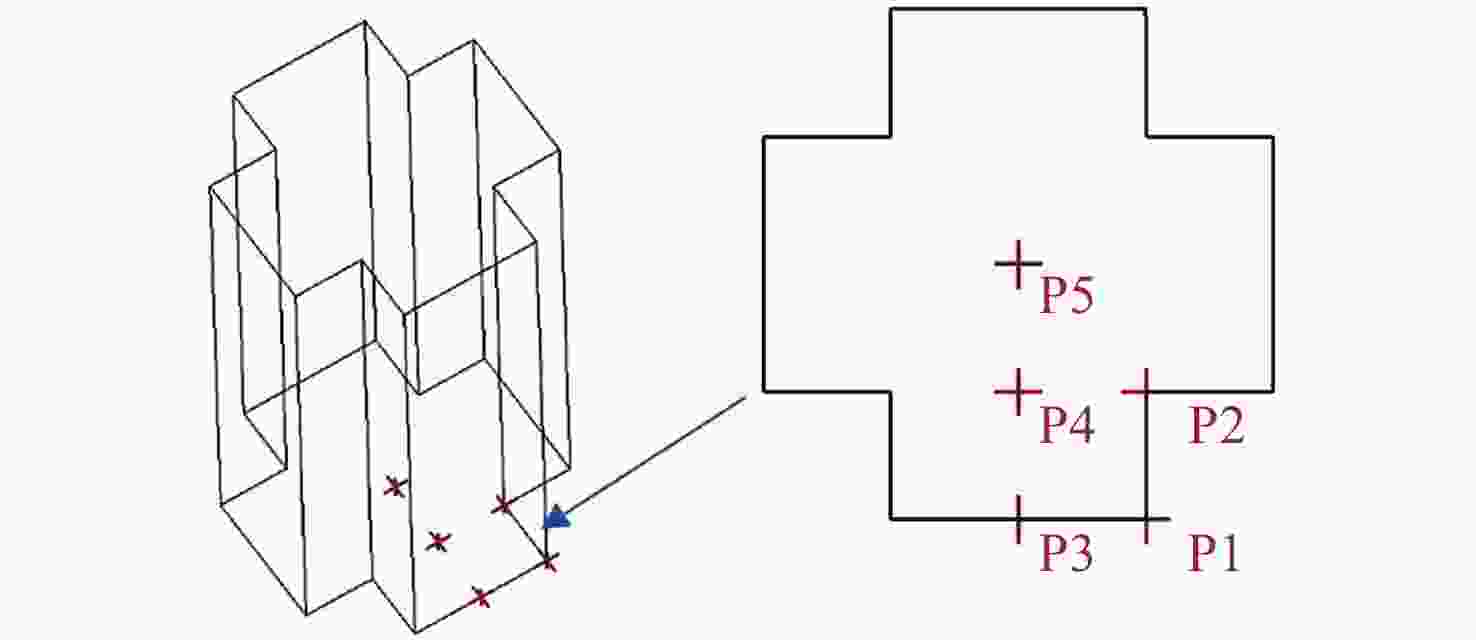

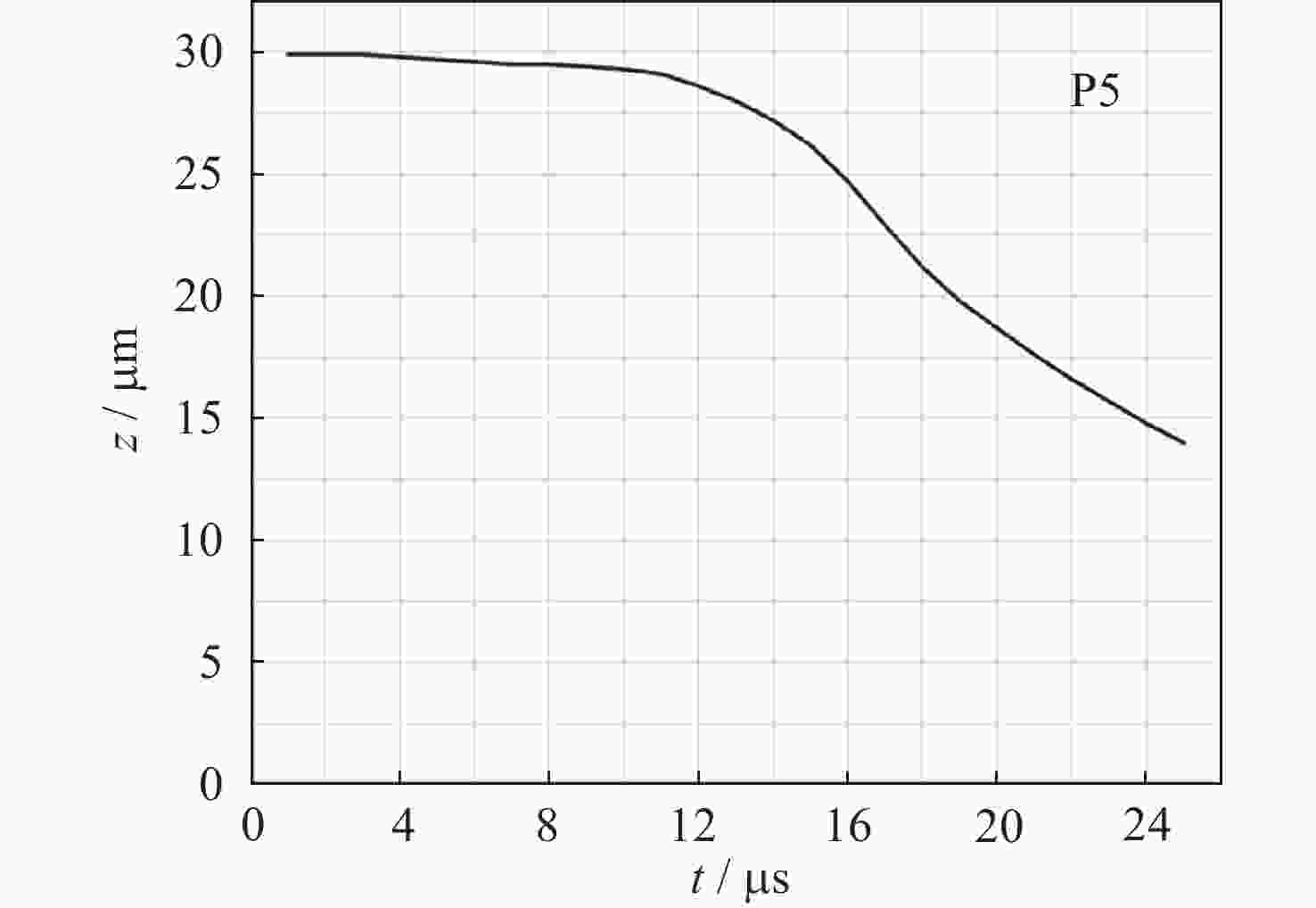

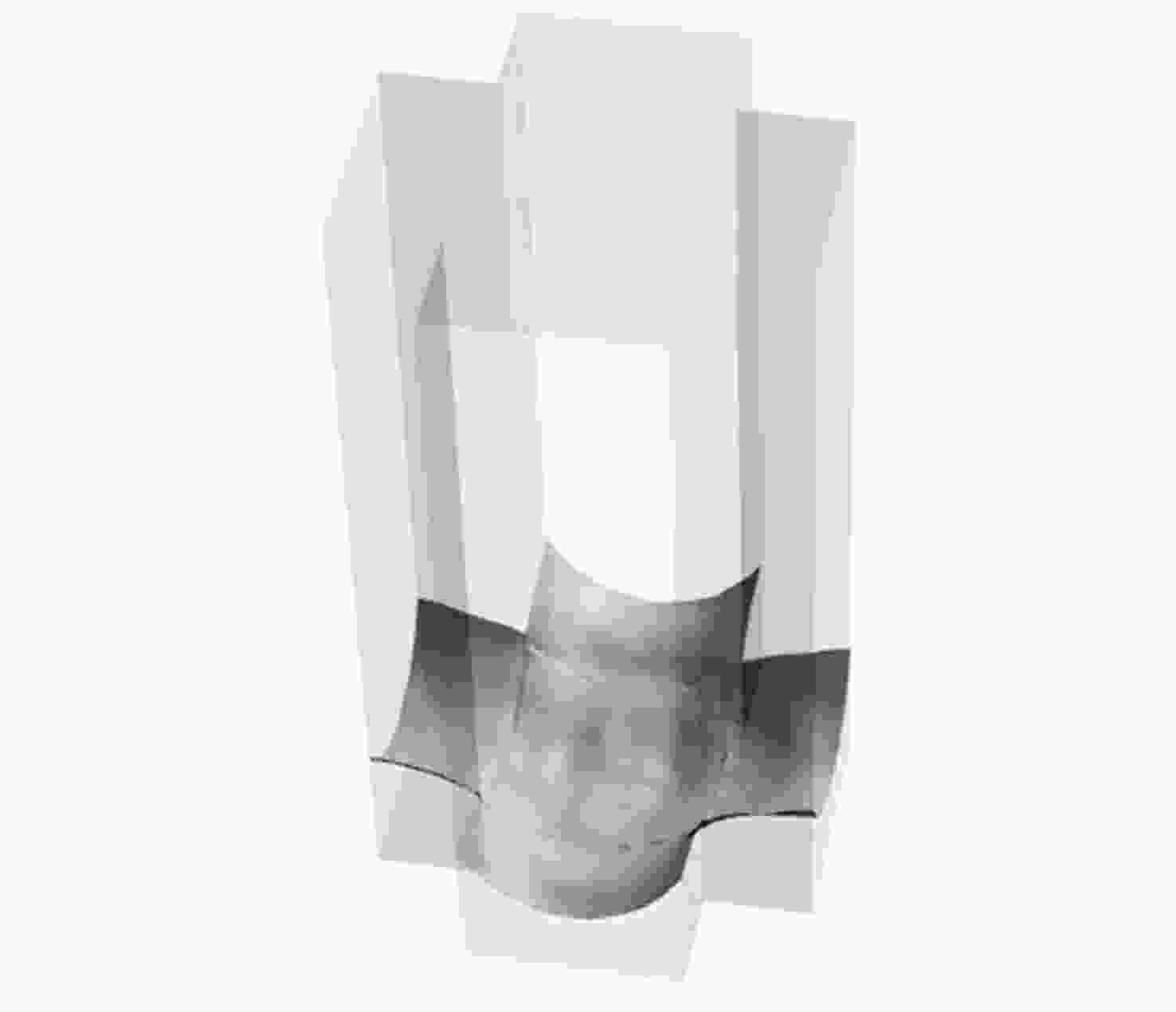

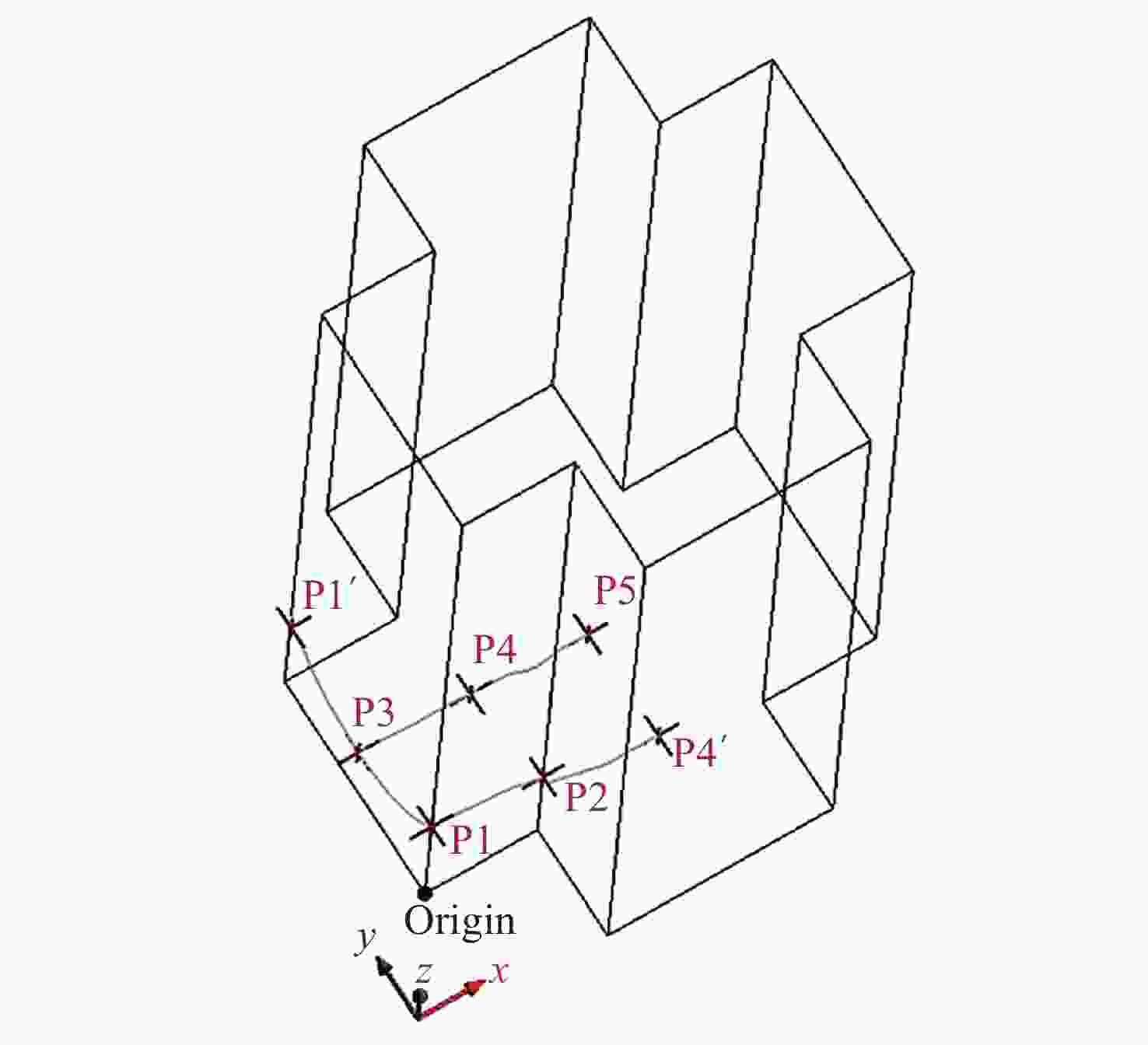

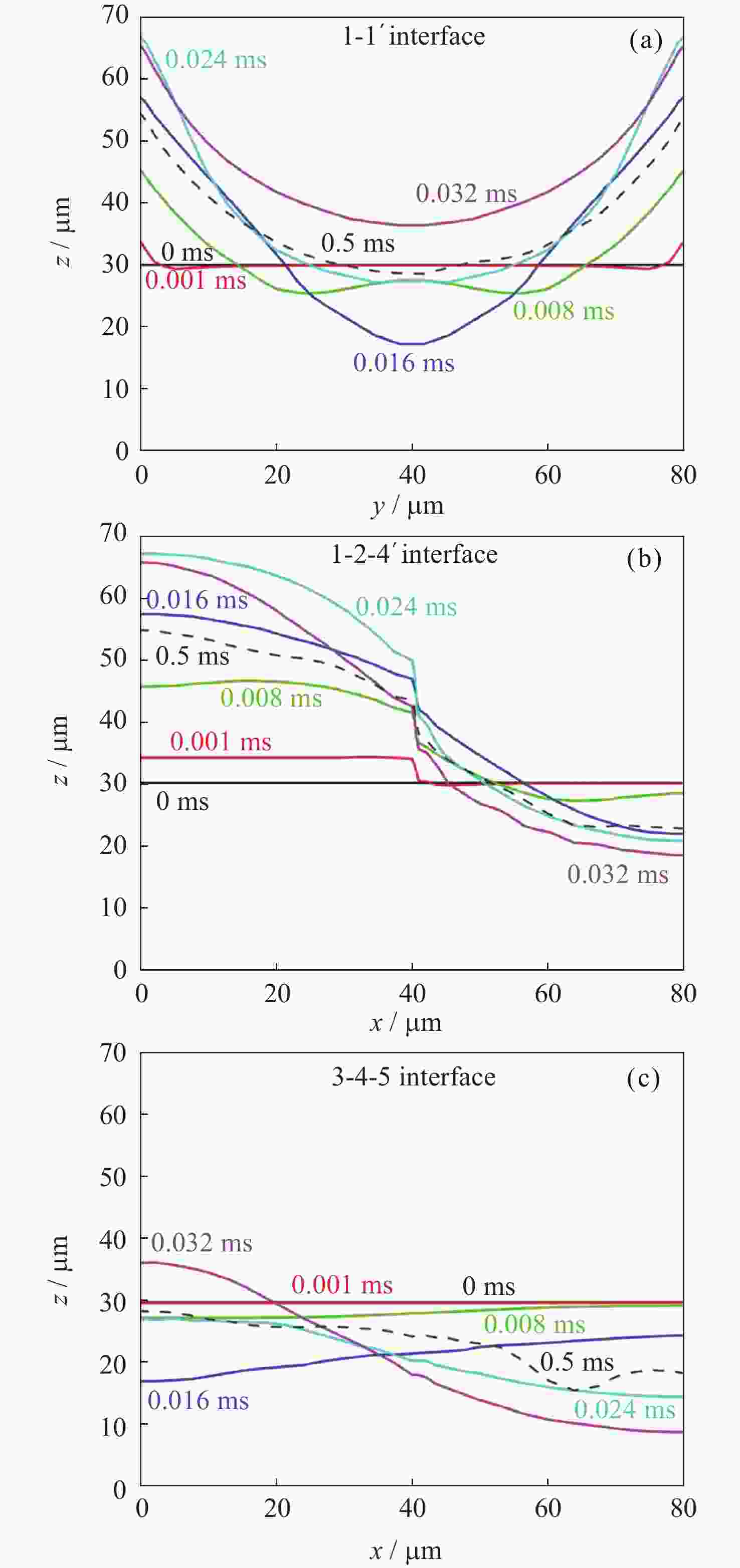

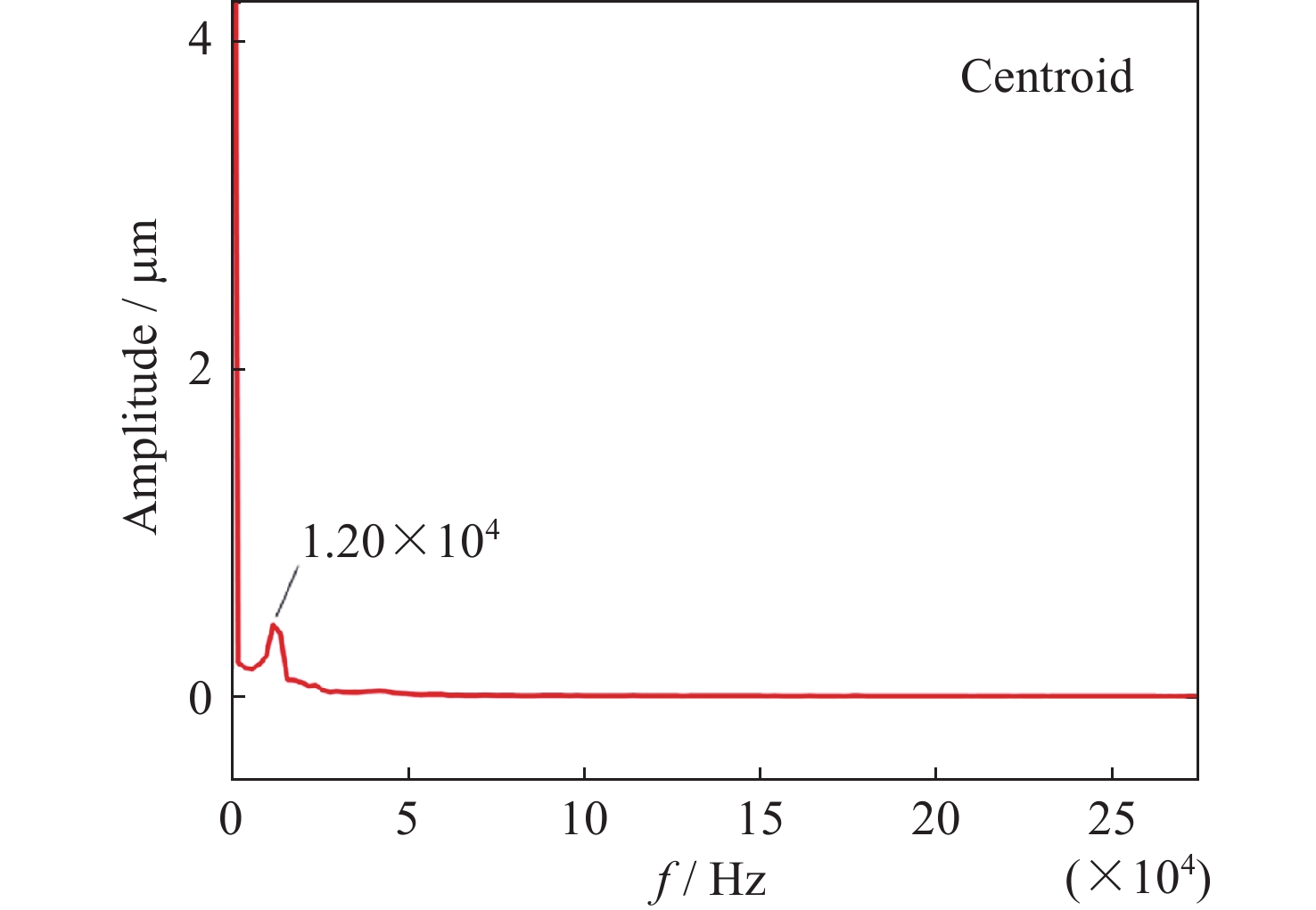

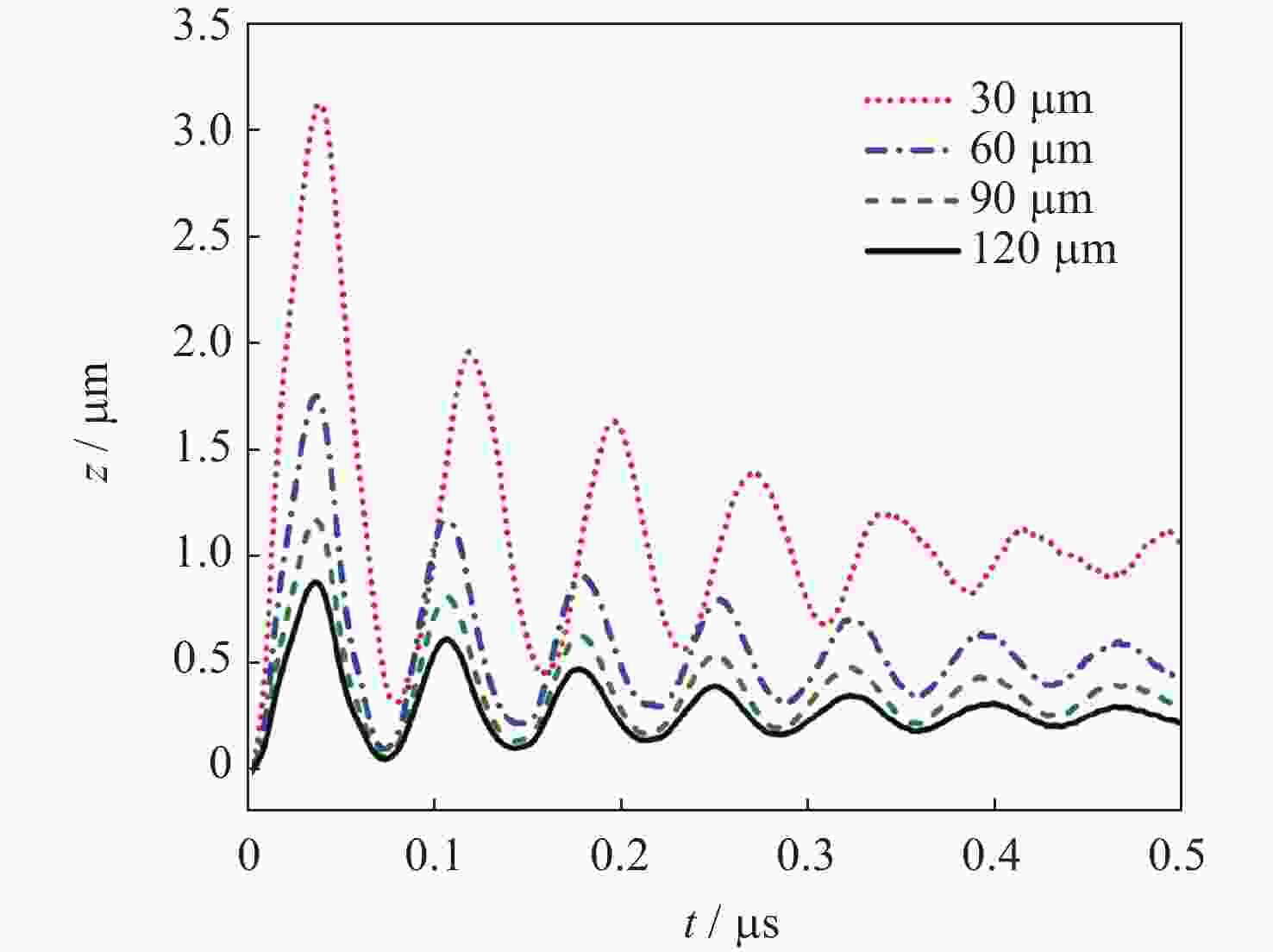

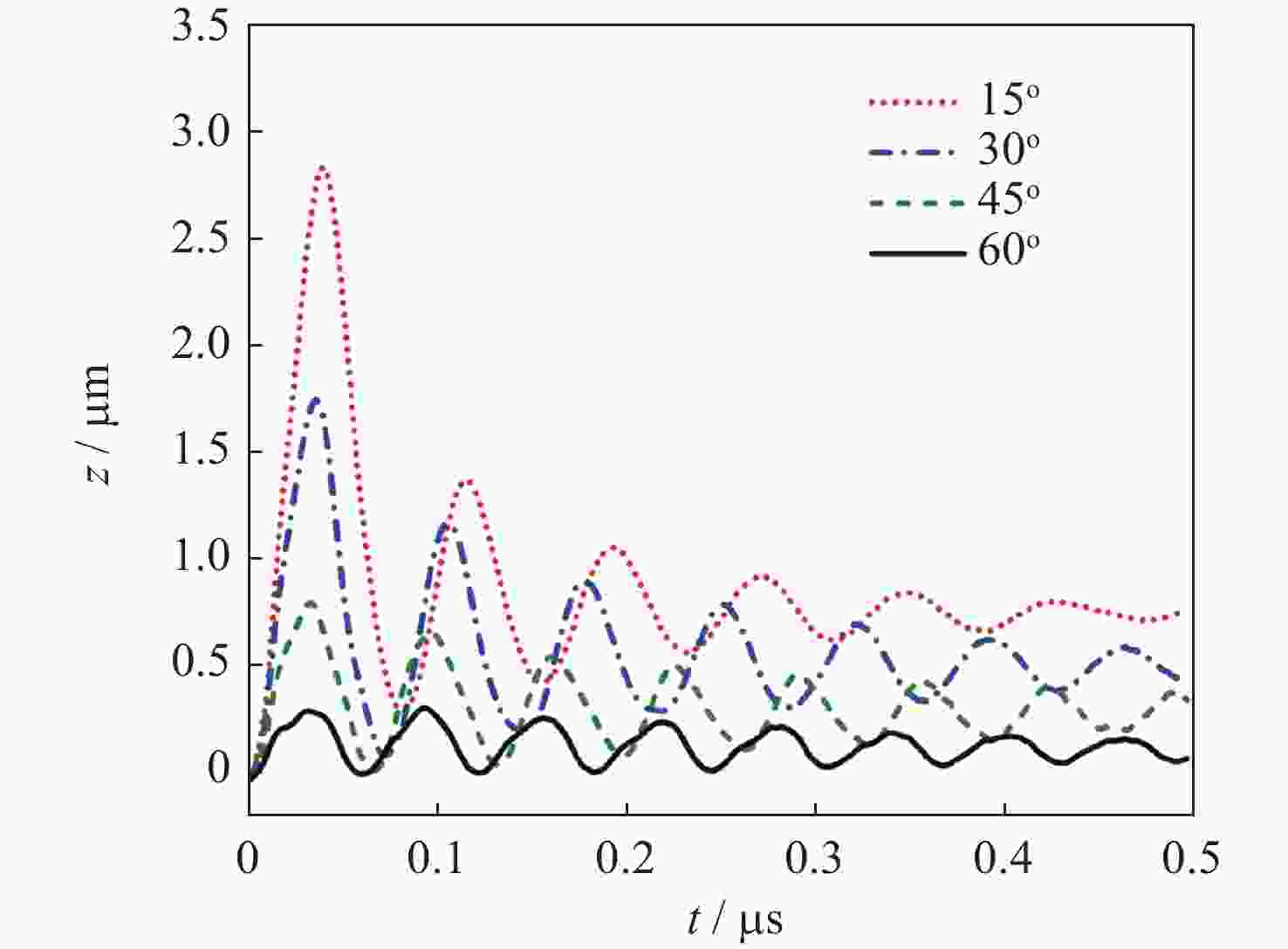

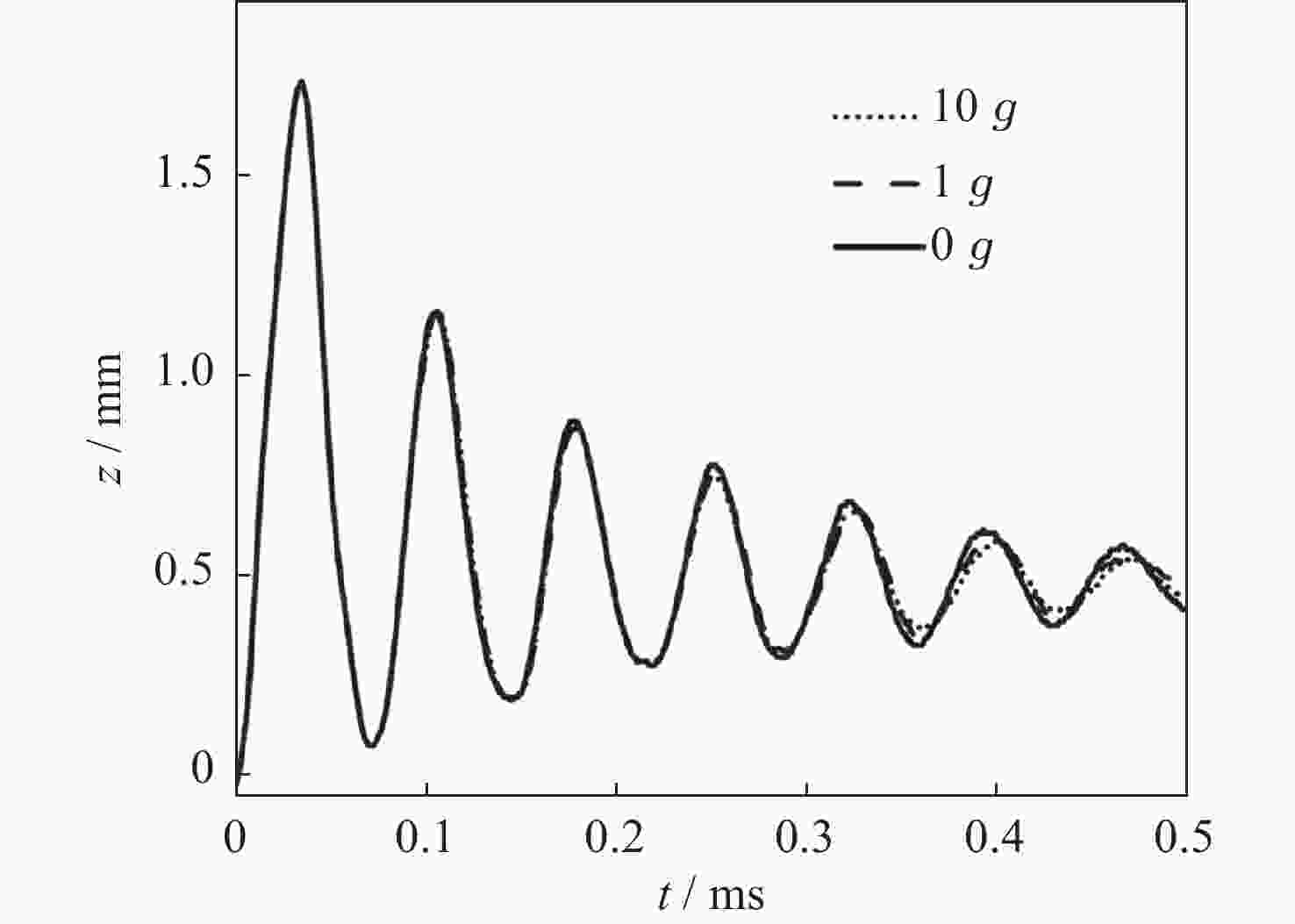

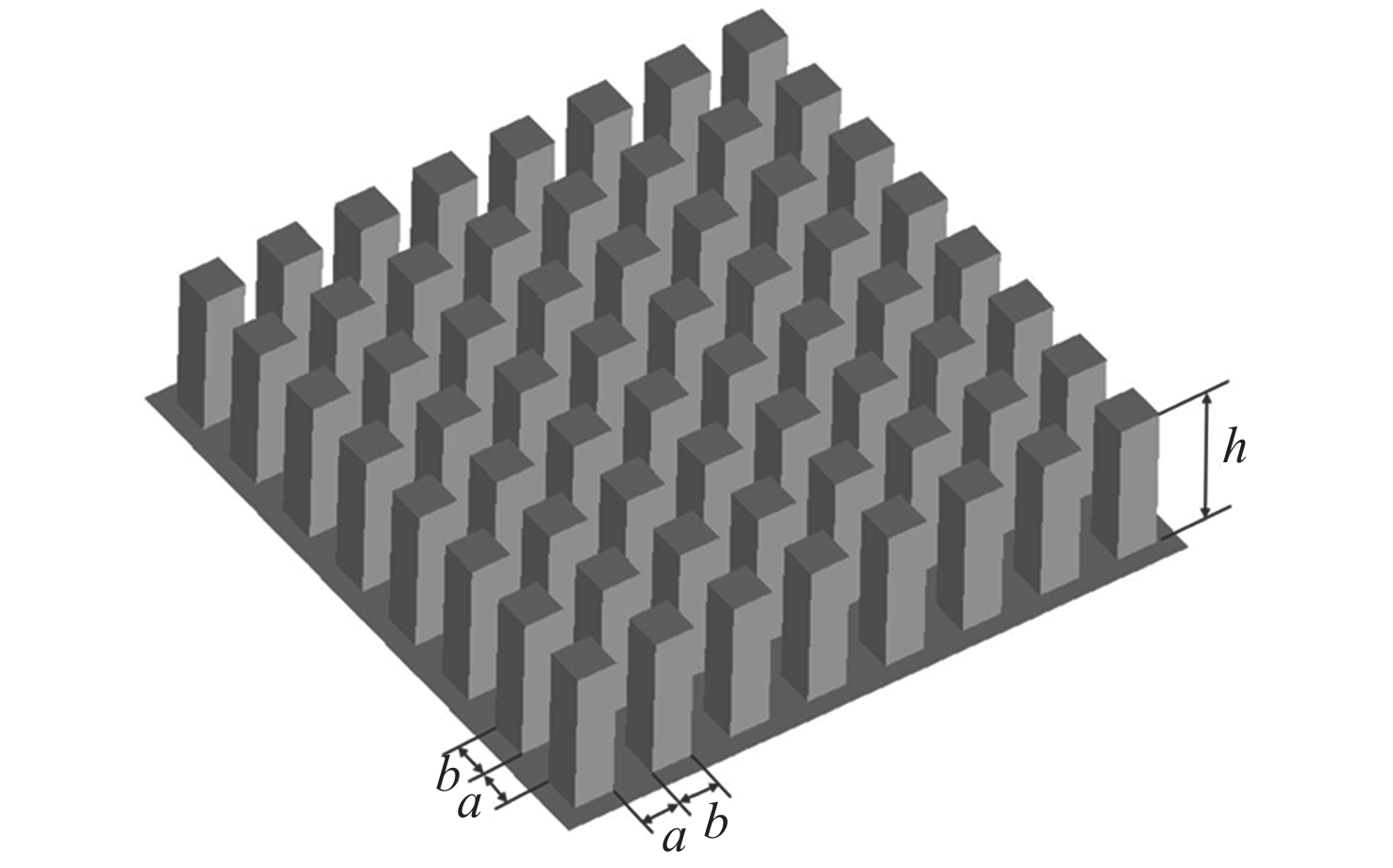

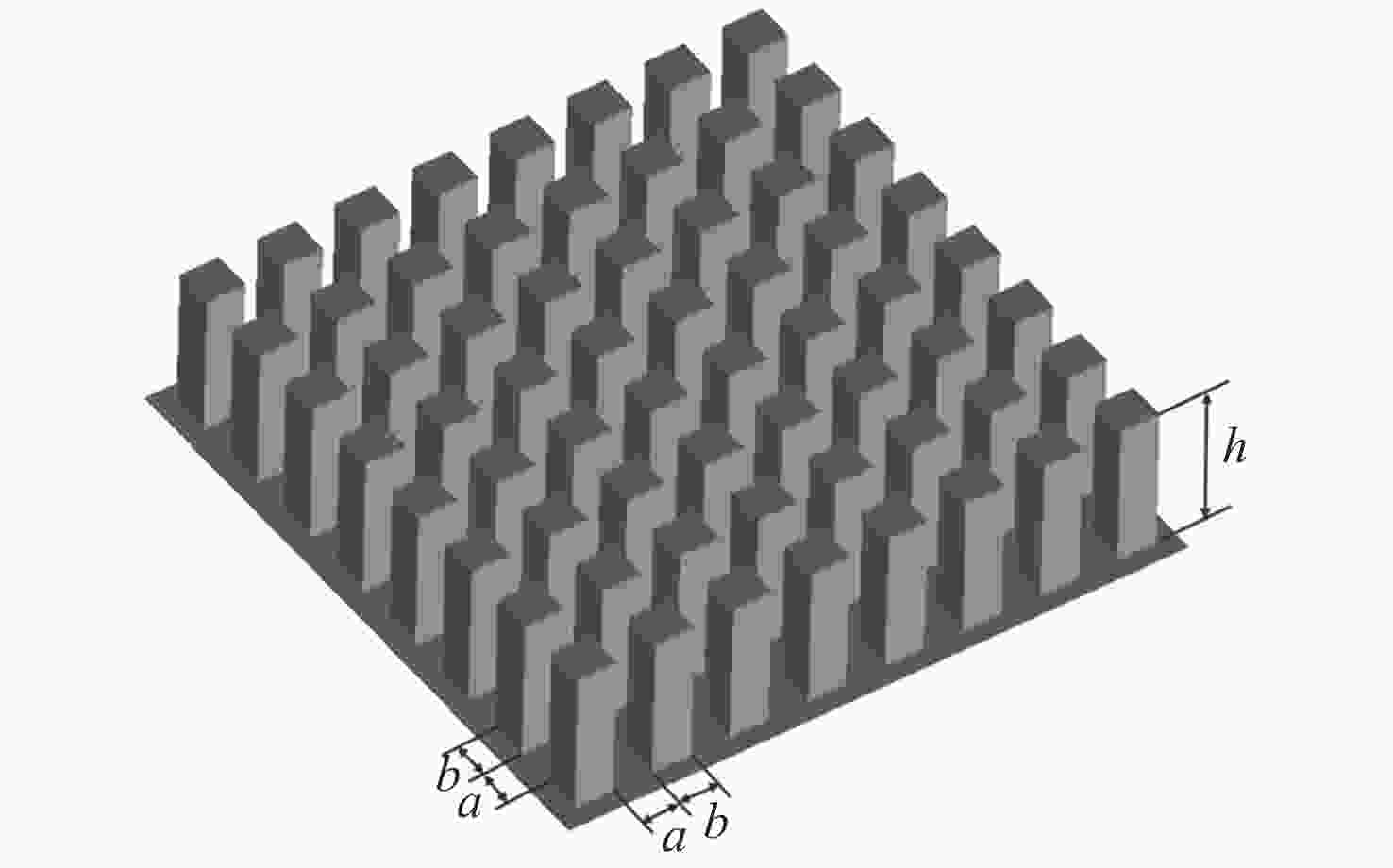

摘要: 重力突然下降引起的气液界面振荡和重构对空间流体管理具有重要影响. 考虑到贮箱壁面润湿特性在该问题中的重要作用, 借鉴传热强化领域方柱微结构表面设计思想, 提出一种利用方柱微结构壁面对液体振荡的衰减作用实现空间贮箱被动防晃的方法. 采用流体体积法(VOF)对一种方柱微结构形成的异形基本单元内气液界面振荡特性进行数值模拟, 分析自由液面随时间的变化特征, 并讨论系统振荡频率、阻尼特性等与能量耗散特性密切相关的参数变化规律. 研究发现, 初始液位主要影响液面振幅, 振幅随着初始液位高度的减小而增大, 但是液位过低时振荡过程会出现液面触底而加剧耗散; 接触角对振幅和阻尼比都有影响, 接触角增大, 振幅和阻尼比均有所减小.Abstract: The oscillation and reconstruction of gas-liquid interface caused by sudden drop of gravity is of great significance to space fluid management. Taking into account of the important role of the tank wall’s wetting characteristics, this paper draws on the idea of designing the surface of the square column micro-structure in the field of heat transfer enhancement, and puts forward a passive anti-shaking idea of the space tank by using the damping effect of the square column micro-structure wall on the liquid oscillation. In addition, the gas-liquid interface oscillation characteristics in a special-shaped basic unit formed by a square column microstructure were numerically simulated by using the Volume of Fluid (VOF) method, and the variation of the free liquid surface characteristics with time was analyzed. In particular, the oscillation frequency, damping characteristics and other parameters closely related to the energy dissipation characteristics of the system were discussed, which provided the reference basis for space applications. The results show that the gas-liquid interface within the square-column microstructure produces a repositioning phenomenon accompanied by damped oscillations when gravity plummets from a strongly overloaded state. The initial liquid level height mainly affects the amplitude of the liquid surface oscillation. An initial liquid level lower than 30 μm leads to a bottoming out of the liquid surface during the oscillation process, which increases the damping ratio. In the absence of bottoming out, the higher the initial level is, the lower the amplitude of the oscillation is. The contact angle affects the amplitude and damping ratio of the oscillation process, and both the amplitude and damping ratio decrease gradually as the contact angle increases. In a wide gravity range, the magnitude of the final gravity level is between microgravity and 10 times normal gravity, the gas-liquid two-phase flow characteristics inside the square-column microstructures are similar, and the gravity effect is rather weak.

-

Key words:

- Microgravity /

- Shake /

- Gas-liquid interface /

- Space fluid management

-

表 1 氨工质的气液两相流体物性参数

Table 1. Physical properties of gas and liquid phase of ammonia

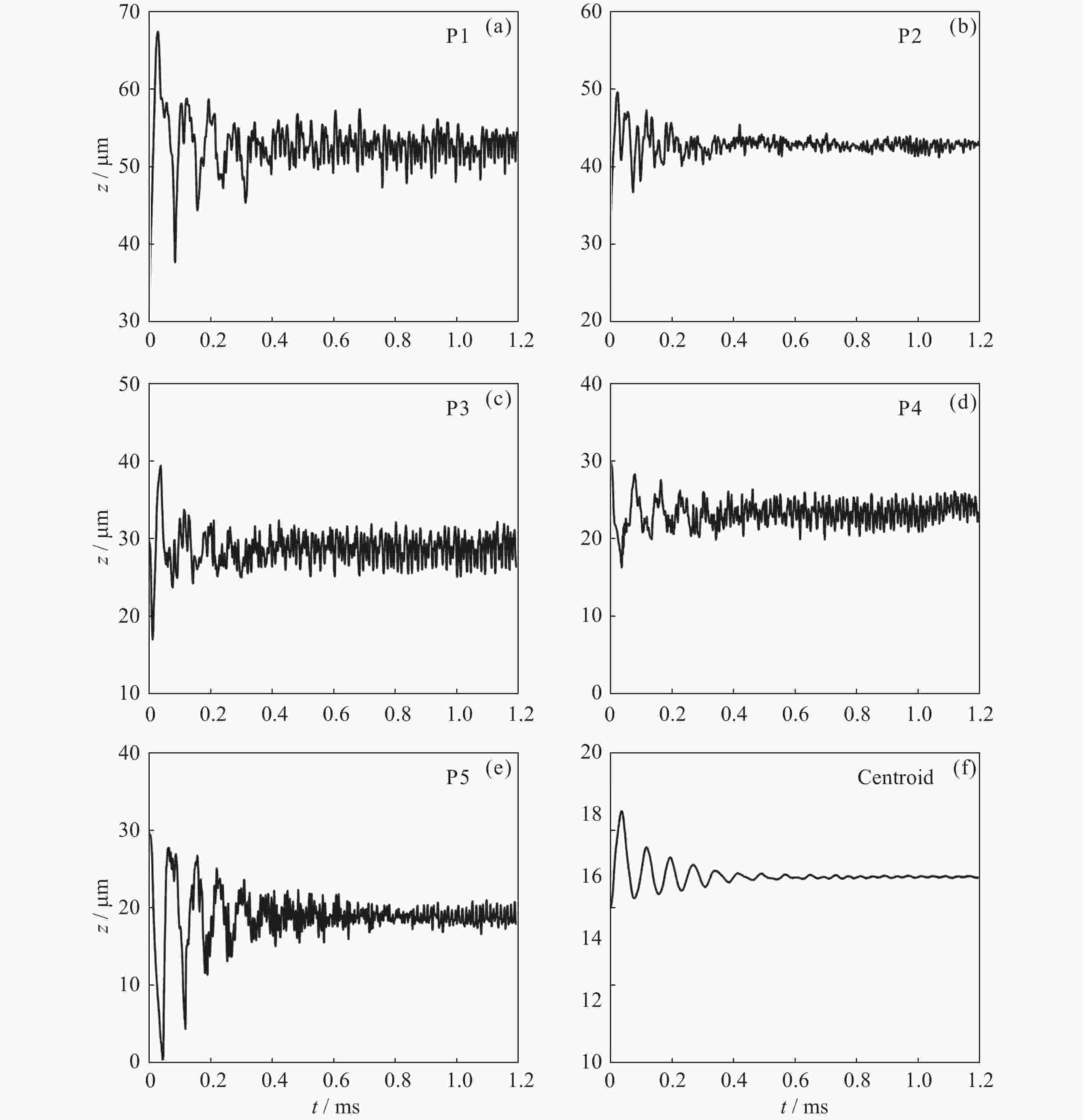

特性 气体 液体 密度/(kg·m–3) 6.7 610.2 动力黏度/(μPa$ \cdot $s) 9.68 138.32 表面张力/(N·m–1) 0.0072 接触角/(°) 30 表 2 特征点和质心的振动拟合参数

Table 2. Vibration fitting parameters of feature points and centroid

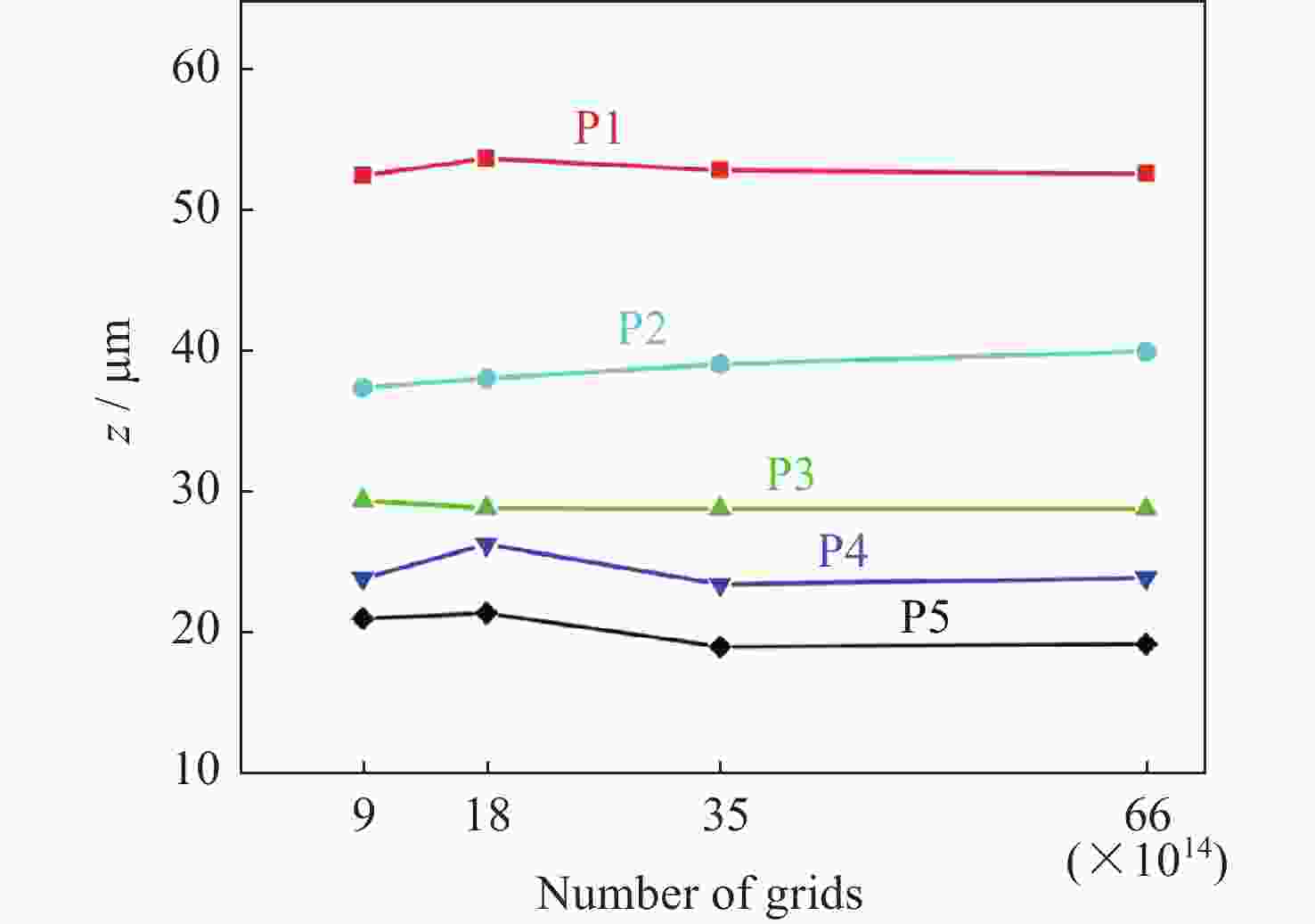

Point $ A_0 $/mm $ \zeta $ $ {\omega }_{\mathrm{d}} $/(rad·s–1) 1 1.90×10–5 0.0776 78000 2 7.00×10–6 0.0362 170000 3 1.35×10–5 0.0817 78000 4 8.15×10–6 0.0665 78000 5 2.10×10–5 0.0742 78000 质心 1.70×10–6 0.0793 75398 表 3 不同初始液位下的振动拟合参数

Table 3. Vibration fitting parameters at different initial liquid levels

h/μm $ {A}_{0} $/mm $ \zeta $ $ {\omega }_{\mathrm{d}} $/(rad·s–1) 20 1.1×10–6 0.0713 64114 30 1.7×10–6 0.0793 75398 60 1.0×10–6 0.0624 87965 90 7.0×10–7 0.0624 87965 120 5.0×10–7 0.0624 87965 表 4 不同接触角下的振动拟合参数

Table 4. Vibration fitting parameters at different contact angles

θ $ {A}_{0} $/mm $ \zeta $ $ {\omega }_{\mathrm{d}} $/(rad·s–1) 15° 1.6×10–6 0.1055 75398 30° 1.0×10–6 0.0624 87965 45° 4.0×10–7 0.0298 100530 60° 1.6×10–7 0.0219 100530 -

[1] AKYILDIZ H. A numerical study of the effects of the vertical baffle on liquid sloshing in two-dimensional rectangular tank[J]. Journal of Sound and Vibration, 2012, 331(1): 41-52 doi: 10.1016/j.jsv.2011.08.002 [2] IBRAHIM R A, HEINRICH R T. Experimental investigation of liquid sloshing under parametric random excitation[J]. Journal of Applied Mechanics, 1988, 55(2): 467-473 doi: 10.1115/1.3173701 [3] CUI D L, YAN S Z, GUO X S, et al. Parametric resonance of liquid sloshing in partially filled spacecraft tanks during the powered-flight phase of rocket[J]. Aerospace Science and Technology, 2014, 35: 93-105 doi: 10.1016/j.ast.2014.03.006 [4] DALMON A, LEPILLIEZ M, TANGUY S, et al. Comparison between the FLUIDICS experiment and direct numerical simulations of fluid sloshing in spherical tanks under microgravity conditions[J]. Microgravity Science and Technology, 2019, 31(1): 123-138 doi: 10.1007/s12217-019-9675-4 [5] YANG W J, ZHANG T T, LI C, et al. Numerical simulation of pitching sloshing under microgravity[J]. Journal of Applied Fluid Mechanics, 2019, 12(5): 1527-1537 doi: 10.29252/jafm.12.05.29677 [6] ARNDT T, DREYER M. Damping behavior of sloshing liquid in laterally excited cylindrical propellant vessels[J]. Journal of Spacecraft and Rockets, 2008, 45(5): 1085-1088 doi: 10.2514/1.35019 [7] LI J C, LIN H, ZHAO J F, et al. Dynamic behaviors of liquid in partially filled tank in short-term microgravity[J]. Microgravity Science and Technology, 2018, 30(6): 849-856 doi: 10.1007/s12217-018-9642-5 [8] 魏列, 杜王芳, 薛子扬, 等. 重力跳变引起的贮箱内气液界面波传播规律[J]. 空间科学学报, 2023, 43(5): 875-882 doi: 10.11728/cjss2023.05.2023-yg12WEI Lie, DU Wangfang, XUE Ziyang, et al. Wave propagation law at the gas-liquid interface in a storage tank due to gravity jumps[J]. Chinese Journal of Space Science, 2023, 43(5): 875-882 doi: 10.11728/cjss2023.05.2023-yg12 [9] 苗楠, 王天舒, 李俊峰. 微重环境下液体晃动研究进展[J]. 力学与实践, 2016, 38(3): 229-236 doi: 10.6052/1000-0879-15-185MIAO Nan, WANG Tianshu, LI Junfeng. Research progress of liquid sloshing in microgravity[J]. Mechanics in Engineering, 2016, 38(3): 229-236 doi: 10.6052/1000-0879-15-185 [10] AOKI K, NAKAMURA T, IGARASHI I, et al. Experimental investigation of baffle effectiveness on nonlinear propellant sloshing in RLV[C]//43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit. Cincinnati: AIAA, 2007 [11] MALEKI A, ZIYAEIFAR M. Sloshing damping in cylindrical liquid storage tanks with baffles[J]. Journal of Sound and Vibration, 2008, 311(1/2): 372-385 [12] 杨唱, 孙冰, 方杰. 航天器贮箱出流过程液体晃动及防晃[J]. 航空动力学报, 2018, 33(12): 3065-3072YANG Chang, SUN Bing, FANG Jie. Liquid sloshing and anti-sloshing of spacecraft tank during outflow[J]. Journal of Aerospace Power, 2018, 33(12): 3065-3072 [13] 于瑾, 李宝海, 王求生, 等. 贮箱防晃挡板结构形式和晃动阻尼研究[J]. 导弹与航天运载技术, 2021(5): 147-149, 154YU Jin, LI Baohai, WANG Qiusheng, et al. The research of sloshing suppression baffle structure and slosh damping of propellant tank[J]. Missiles and Space Vehicles, 2021(5): 147-149, 154 [14] WÖLK G, DREYER M, RATH H J, et al. Damped oscillations of a liquid/gas surface upon step reduction in gravity[J]. Journal of Spacecraft and Rockets, 1997, 34(1): 110-117 doi: 10.2514/2.3179 [15] GERSTMANN J, DREYER M E, RATH H J. Surface reorientation upon step reduction in gravity[J]. AIP Conference Proceedings, 2000, 504(1): 847-853 [16] MICHAELIS M, DREYER M E, RATH H J. Experimental investigation of the liquid interface reorientation upon step reduction in gravity[J]. Annals of the New York Academy of Sciences, 2002, 974(1): 246-260 doi: 10.1111/j.1749-6632.2002.tb05911.x [17] MICHAELIS M, GERSTMANN J, DREYER M E, et al. Damping behavior of the free liquid interface oscillation upon step reduction in gravity[J]. Proceedings in Applied Mathematics and Mechanics, 2003, 2(1): 320-321 doi: 10.1002/pamm.200310144 [18] LI J C, LIN H, LI K, et al. Liquid sloshing in partially filled capsule storage tank undergoing gravity reduction to low/micro-gravity condition[J]. Microgravity Science and Technology, 2020, 32(4): 587-596 doi: 10.1007/s12217-020-09801-3 [19] LI J C, LIN H, LI K, et al. Dynamic behavior in a storage tank in reduced gravity using dynamic contact angle method[J]. Microgravity Science and Technology, 2020, 32(6): 1039-1048 doi: 10.1007/s12217-020-09831-x [20] ÖNER D, MCCARTHY T J. Ultrahydrophobic surfaces. Effects of topography length scales on wettability[J]. Langmuir, 2000, 16(20): 7777-7782 doi: 10.1021/la000598o [21] YOSHIMITSU Z, NAKAJIMA A, WATANABE T, et al. Effects of surface structure on the hydrophobicity and sliding behavior of water droplets[J]. Langmuir, 2002, 18(15): 5818-5822 doi: 10.1021/la020088p [22] LIU B, LANGE F F. Pressure induced transition between superhydrophobic states: Configuration diagrams and effect of surface feature size[J]. Journal of Colloid and Interface Science, 2006, 298(2): 899-909 doi: 10.1016/j.jcis.2006.01.025 [23] 张永海, 薛艳芳, 魏进家, 等. 微重力下微结构表面池沸腾气泡动力学研究[J]. 工程热物理学报, 2013, 34(11): 2112-2115ZHANG Yonghai, XUE Yanfang, WEI Jinjia, et al. Pool boiling heat transfer and bubble dynamics over micro-pin-finned surface under microgravity[J]. Journal of Engineering Thermophysics, 2013, 34(11): 2112-2115 [24] 薛艳芳, 魏进家, 赵建福, 等. 微重力下微结构表面强化沸腾换热研究[J]. 工程热物理学报, 2012, 33(3): 441-444XUE Yanfang, WEI Jinjia, ZHAO Jianfu, et al. Boiling heat transfer enhancement by using micro-structure surface under microgravity[J]. Journal of Engineering Thermophysics, 2012, 33(3): 441-444 [25] 孔新, 张永海, 魏进家, 等. 微结构表面微重力下沸腾换热及临界机理研究[J]. 工程热物理学报, 2023, 44(6): 1587-1593KONG Xin, ZHANG Yonghai, WEI Jinjia, et al. Investigation of boiling heat transfer performance and mechanism of critical heat flux for micro-structured surface under microgravity[J]. Journal of Engineering Thermophysics, 2023, 44(6): 1587-1593 [26] HIRT C W, NICHOLS B D. Volume of fluid (VOF) method for the dynamics of free boundaries[J]. Journal of Computational Physics, 1981, 39(1): 201-225 doi: 10.1016/0021-9991(81)90145-5 [27] 魏列, 杜王芳, 赵建福, 等. 微重力条件下部分充液贮箱气液界面波动特性的数值模拟[J]. 力学学报, 2022, 54(4): 1004-1011 doi: 10.6052/0459-1879-21-645WEI Lie, DU Wangfang, ZHAO Jianfu, et al. Numerical study on gas-liquid interface waves in partially filled tanks under microgravity condition[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(4): 1004-1011 doi: 10.6052/0459-1879-21-645 [28] Weislogel M M. Fluid interface phenomena in a low-gravity environment: recent results from drop tower experimentation[C]//Space Forum. Gordon and Breach Science Publishers, 1998, 3(GRC-E-DAA-TN58785) [29] BOSANQUET C H. LV. On the flow of liquids into capillary tubes[J]. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1923, 45(267): 525-531 doi: 10.1080/14786442308634144 [30] CAI J C, CHEN Y, LIU Y, et al. Capillary imbibition and flow of wetting liquid in irregular capillaries: A 100-year review[J]. Advances in Colloid and Interface Science, 2022, 304: 102654 doi: 10.1016/j.cis.2022.102654 -

-

王素龙 男, 1999年12月出生于江苏省徐州市, 现为中国石油大学(北京)硕士研究生, 主要研究方向为多相流体力学. E-mail:

王素龙 男, 1999年12月出生于江苏省徐州市, 现为中国石油大学(北京)硕士研究生, 主要研究方向为多相流体力学. E-mail:

下载:

下载: