Experimental Study of a Manifold Pin-fin Diamond Heat Sink for High Heat Flux Chips

-

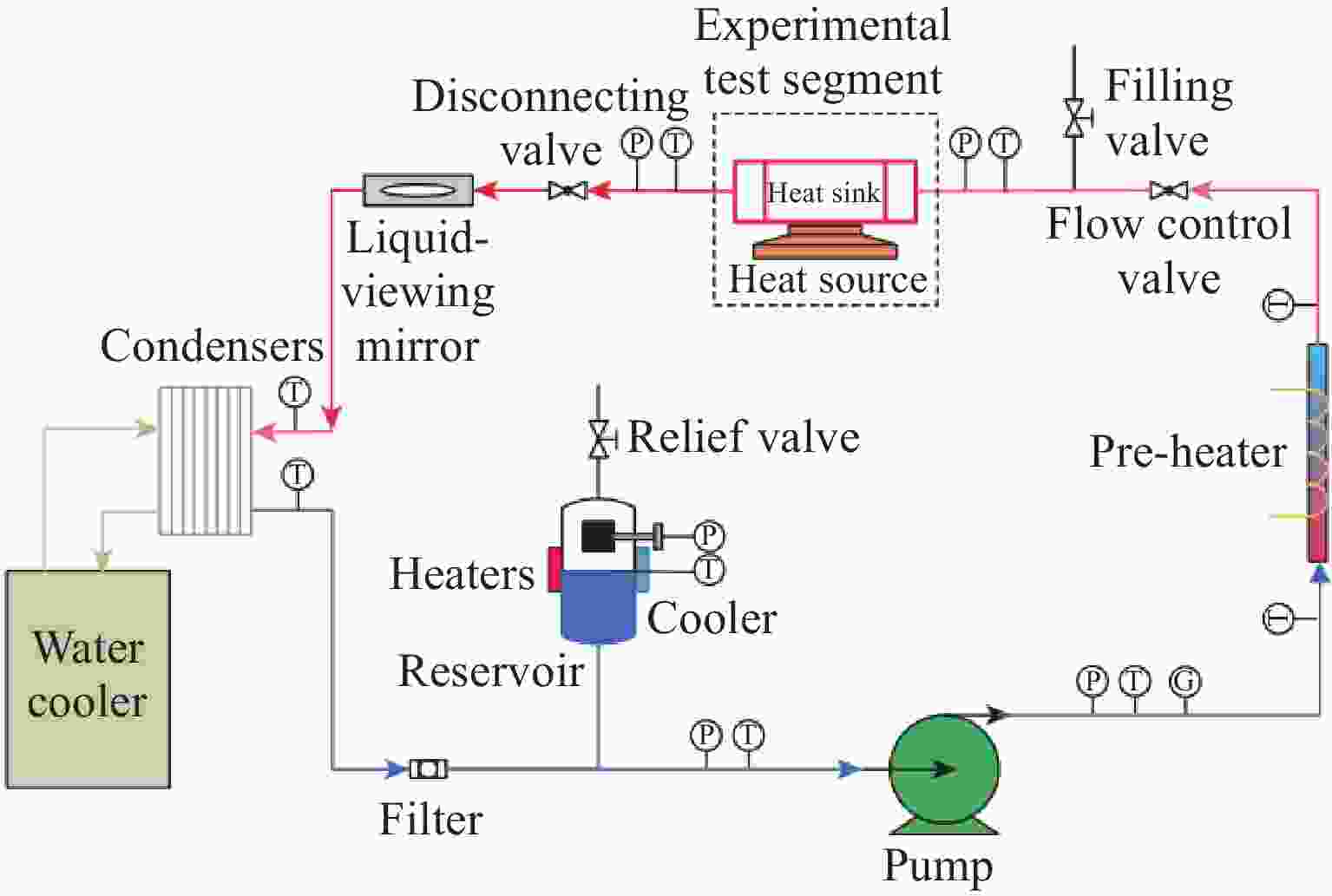

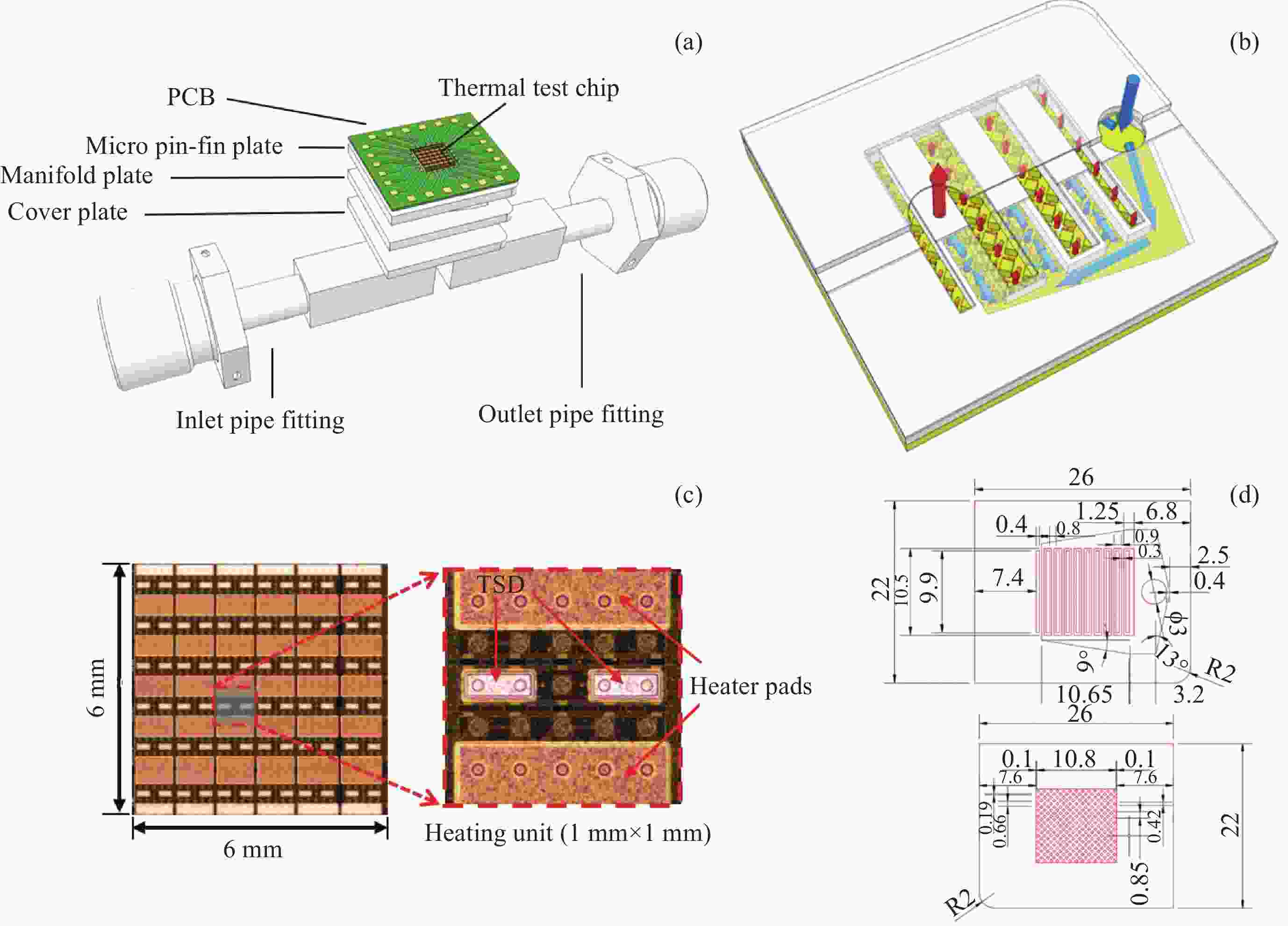

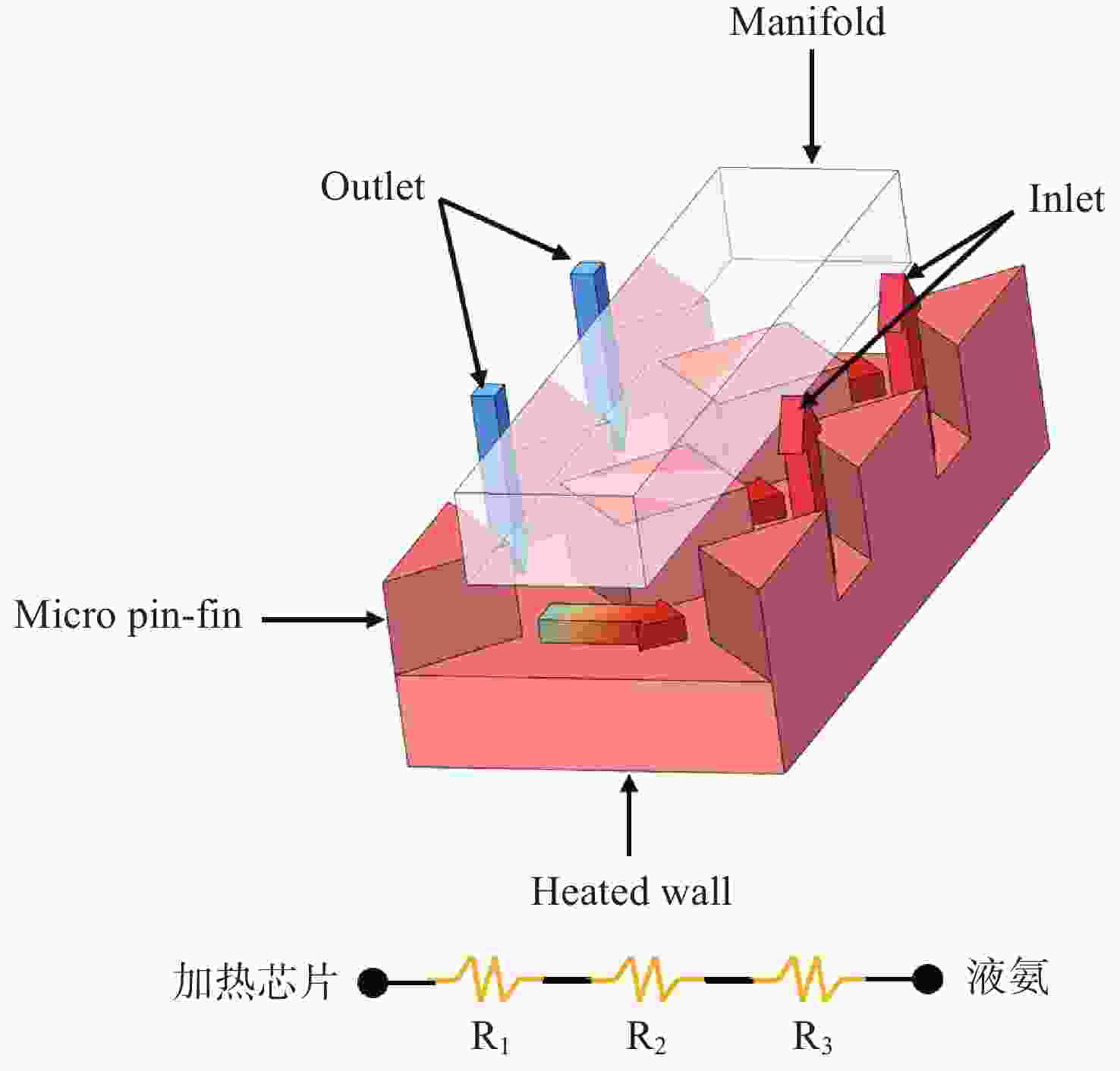

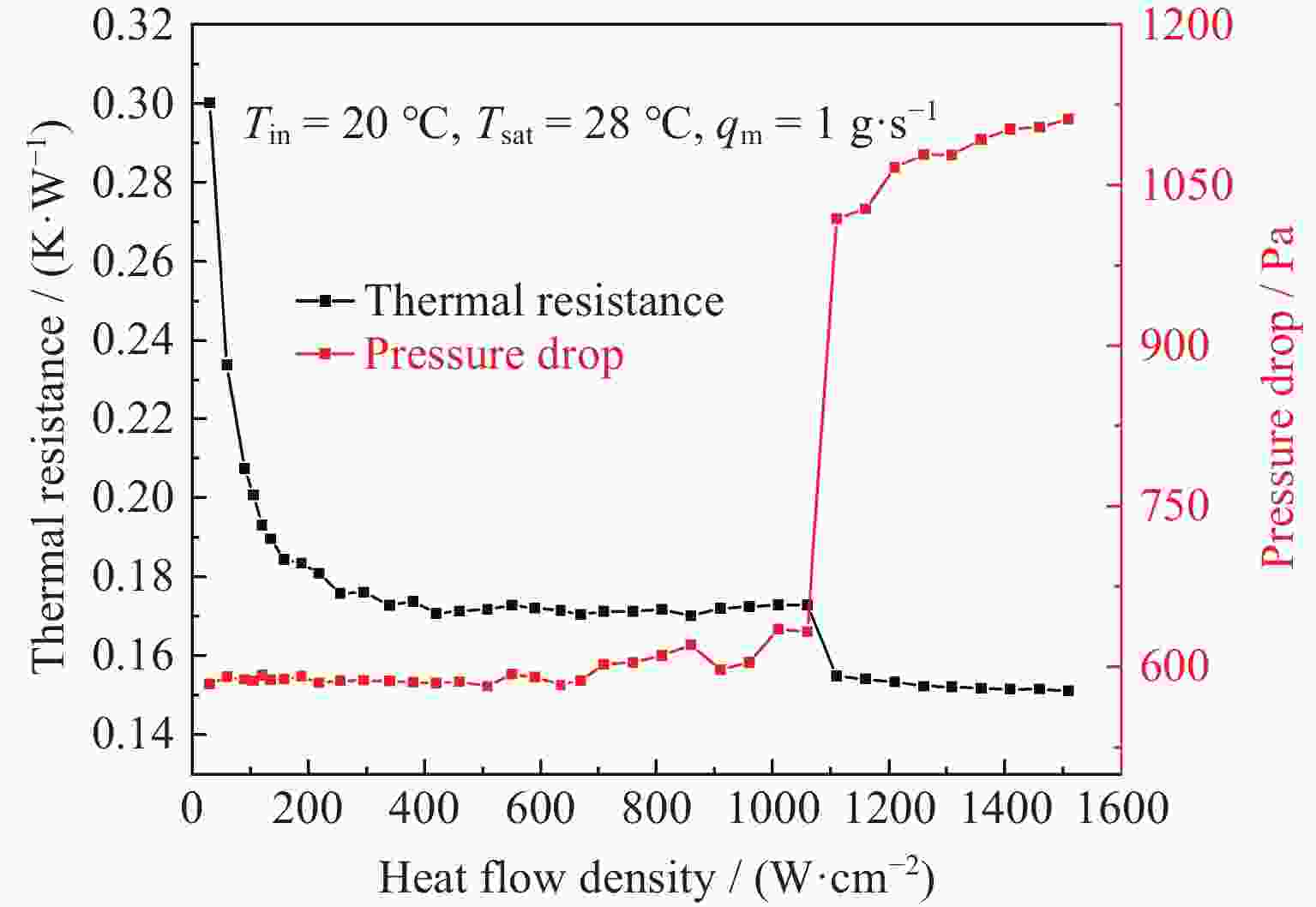

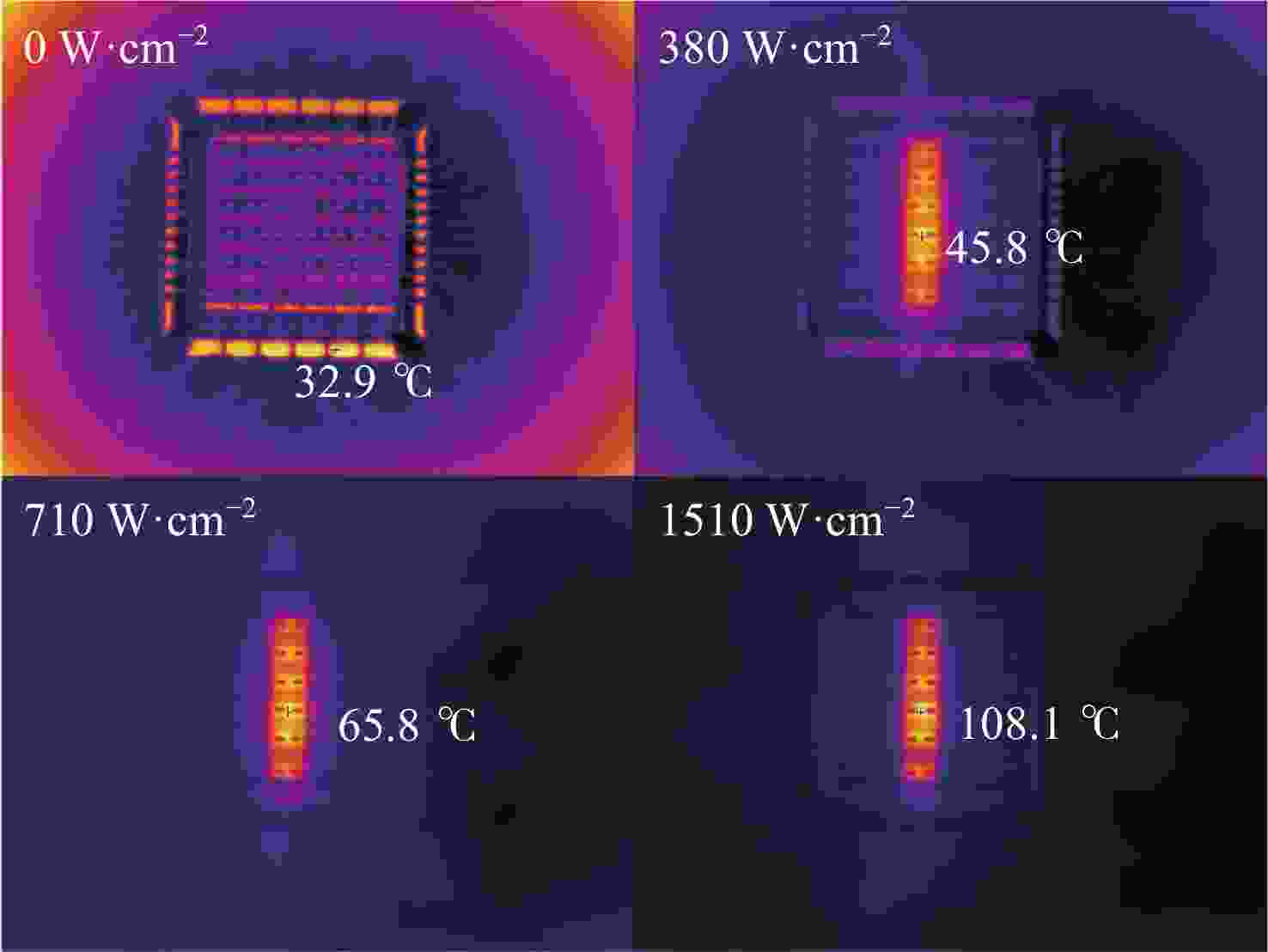

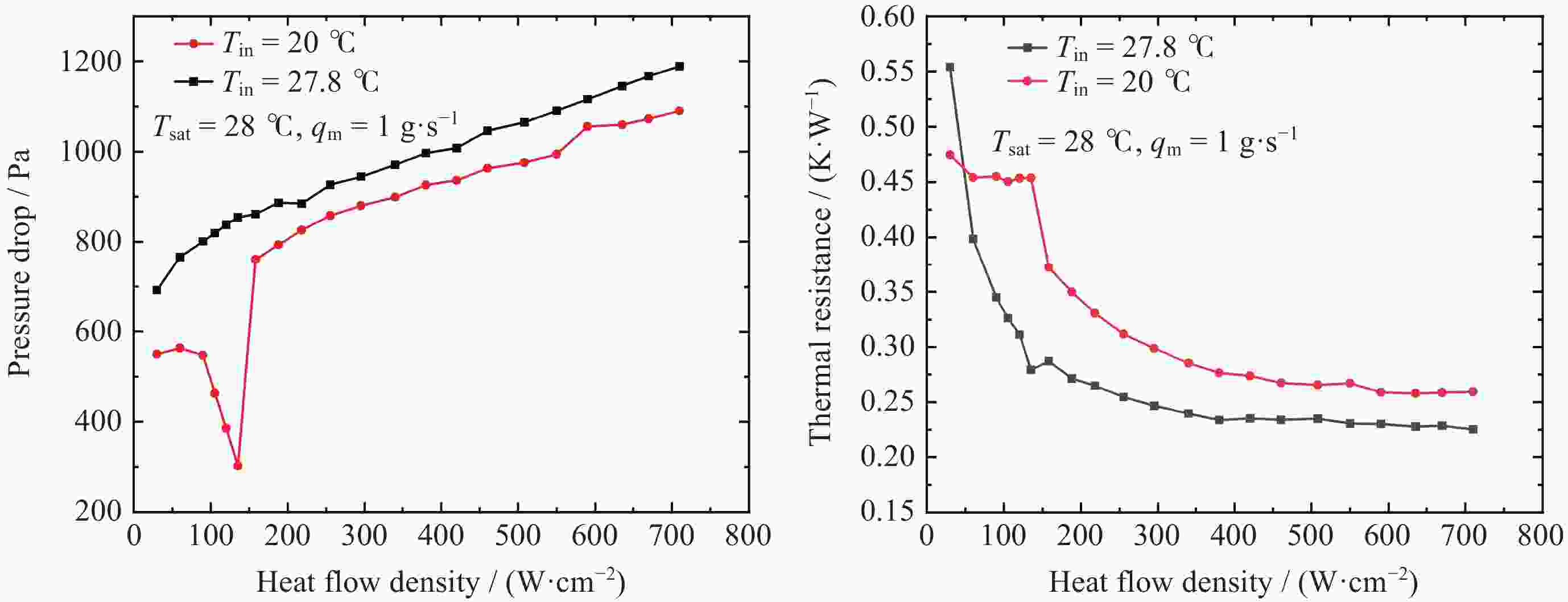

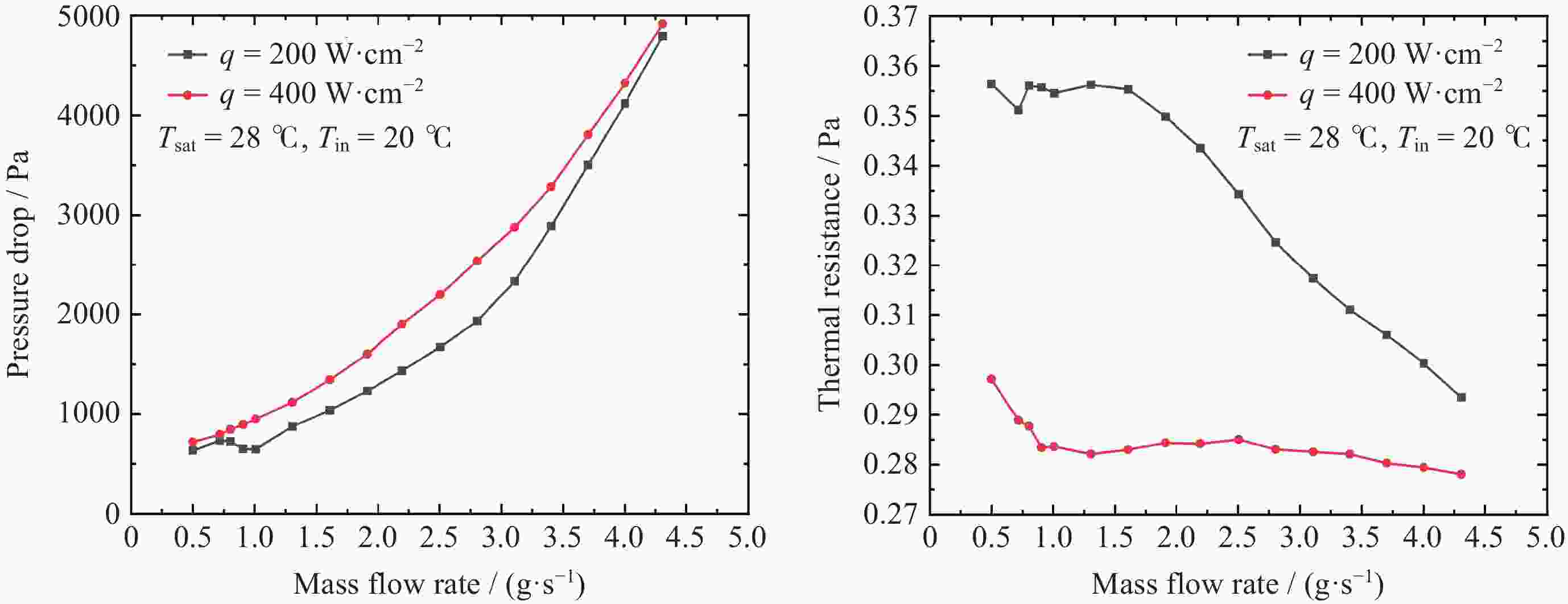

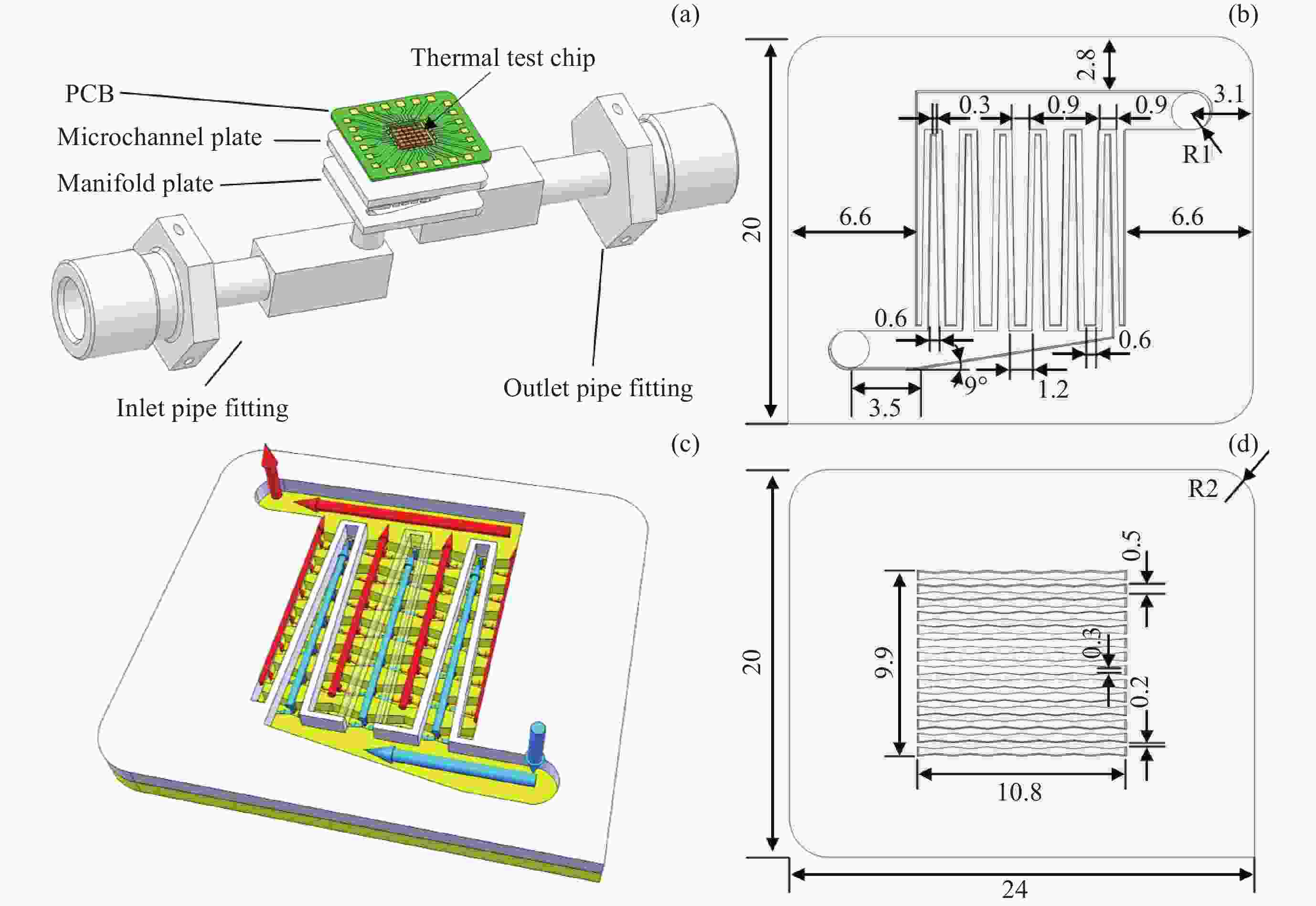

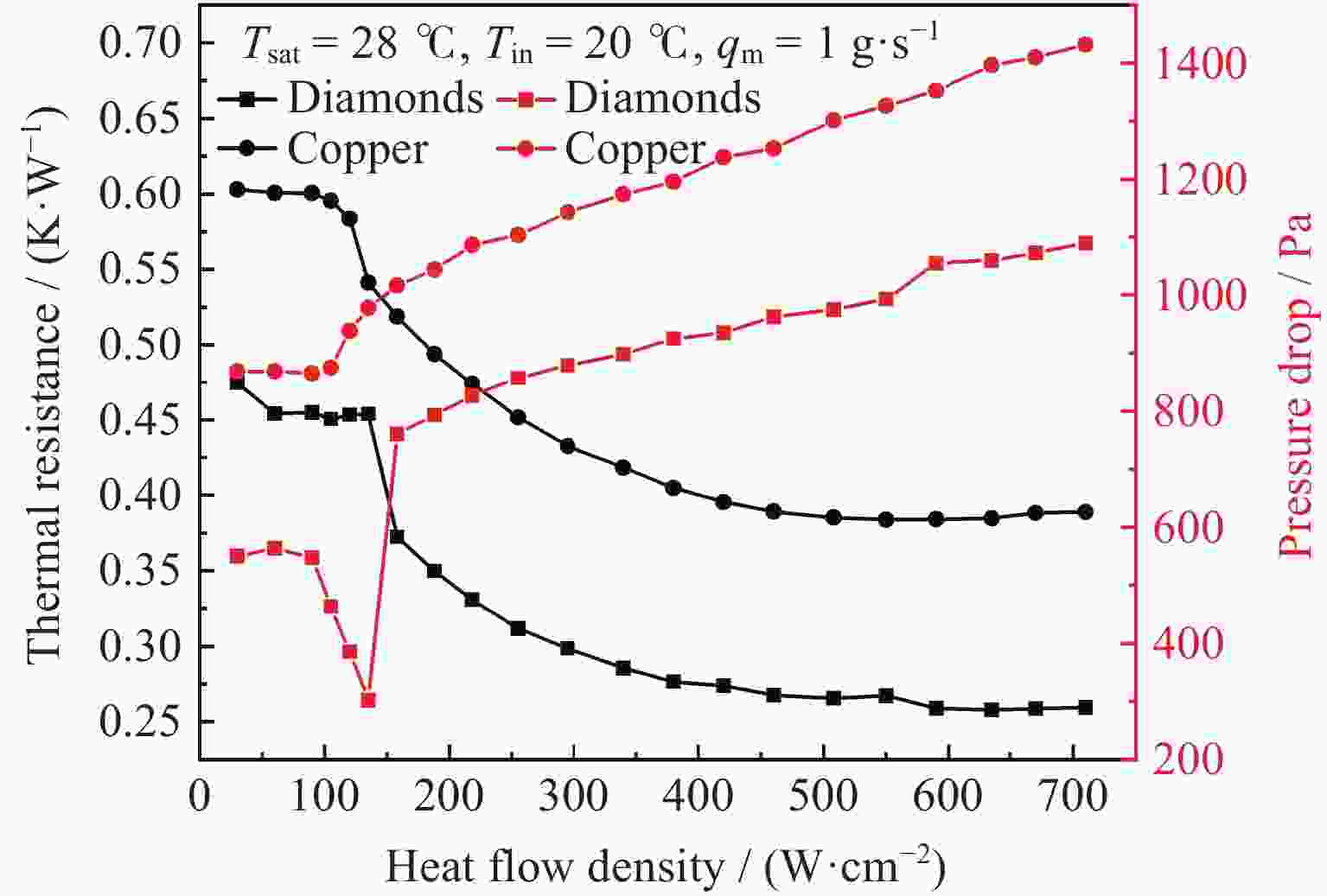

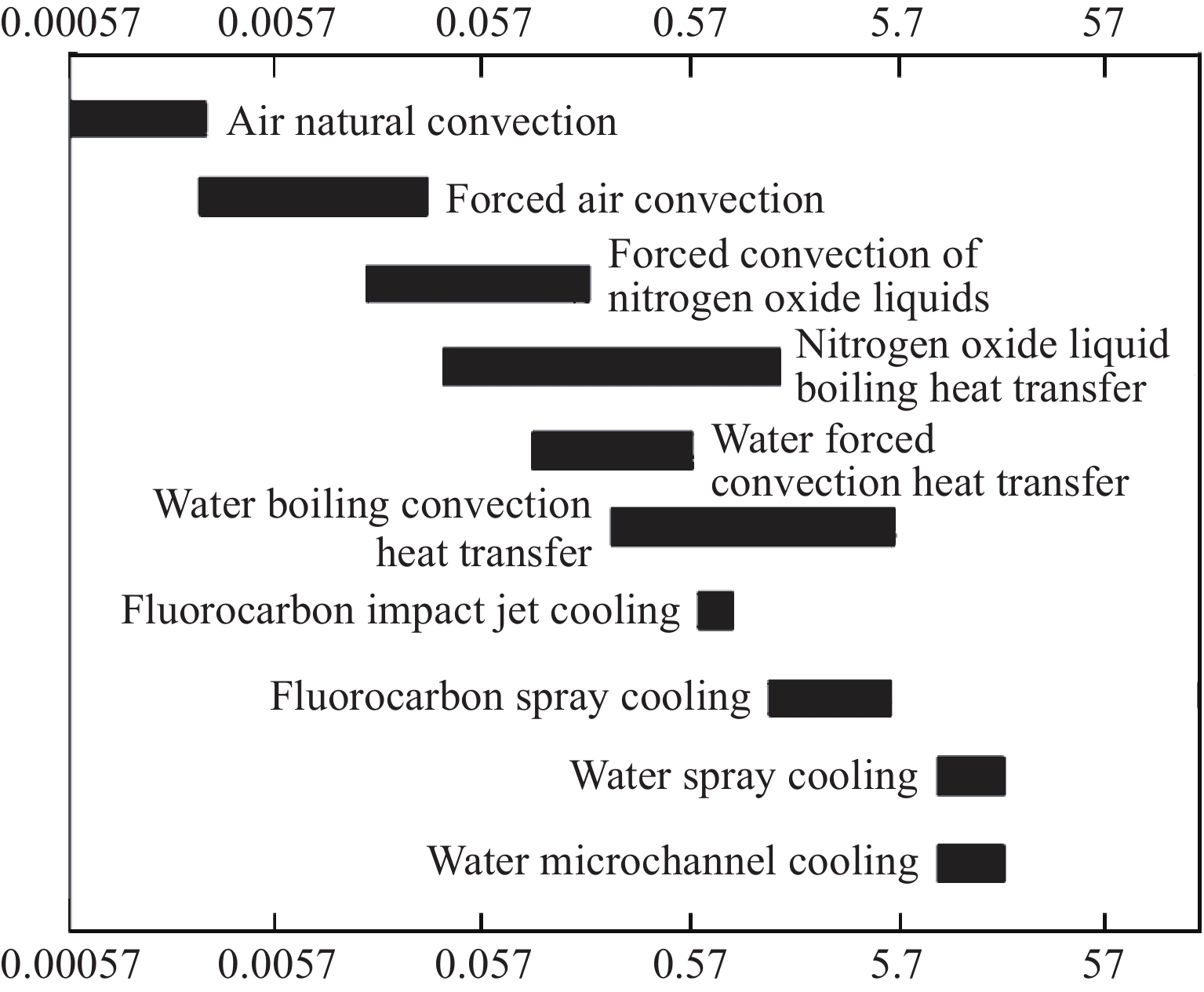

摘要: 微通道散热器是解决高热流密度功率器件的散热难题的有效手段之一, 本文设计并制造了一种适用于高热流散热的金刚石歧管针翅微通道散热器. 利用热测试芯片作为模拟热源, 研究了该散热器在基于氨工质的泵驱两相流回路中的热工性能. 在1510 W·cm–2的局部热流下, 芯片热源表面温度为102.5℃, 热阻为0.151 K·W–1, 压降为1.1 kPa. 研究了进口温度、热流密度、质量流量对散热器热阻和压降的影响, 发现在较高的进口温度条件下散热器的热阻最小. 保持各种工作参数一致, 与铜材质的扩缩流道歧管微通道散热器进行对比, 在710 W·cm–2热流条件下, 金刚石歧管针翅微通道散热器的热阻降低33.32%, 压降降低23.88%.Abstract: A manifold pin-fin microchannel diamond heat sink for high heat flux chips was designed and fabricated. Thermal performance of the heat sink in a pump-driven two-phase ammonia loop was investigated using a thermal test chip as a simulated heat source. Chip surface temperature of 102.5℃ with thermal resistance of 0.151 K·W–1 and pressure drop of 1.1 kPa under localized heat flow of 1510 W·cm–2 were obtained. The effects of inlet temperature, heat flux, and mass flow rate on thermal resistance and pressure drop of the heat sink were investigated, and it was found that the thermal resistance of the heat sink was minimized under higher inlet temperature conditions. Keeping all the other operating parameters consistent, the thermal resistance of the diamond manifold pin-fin microchannel radiator was 33.32% smaller and the pressure drop was 23.88% lower under 710 W·cm–2 heat flow conditions when compared with the expanded and contracted manifold microchannel radiator made of copper.

-

Key words:

- Diamond /

- Manifold pin-fin heatsink /

- Flow boiling /

- Ammonia /

- High heat flux

-

表 1 金刚石热沉和铜热沉对比

Table 1. Comparison of diamond and copper heat sink

金刚石热沉 铜热沉 热沉材质 金刚石 无氧铜 歧管布局 HU三层 Z双层 通道结构 错排针肋 扩缩通道 -

[1] 骆洋. 歧管式微通道内气液流动沸腾换热的数值模拟与实验研究[D]. 杭州: 浙江大学, 2021LUO Yang. Numerical and Experimental Investigation of Liquid-Vapor Two-Phase Flow Boiling in Manifold Micro-channel[D]. Hangzhou: Zhejiang University, 2021 [2] AGOSTINI B, FABBRI M, PARK J E, et al. State of the art of high heat flux cooling technologies[J]. Heat Transfer Engineering, 2007, 28(4): 258-281 doi: 10.1080/01457630601117799 [3] SARKAR S, GUPTA R, ROY T, et al. Review of jet impingement cooling of electronic devices: emerging role of surface engineering[J]. International Journal of Heat and Mass Transfer, 2023, 206: 123888 doi: 10.1016/j.ijheatmasstransfer.2023.123888 [4] CHENG W L, ZHANG W W, CHEN H, et al. Spray cooling and flash evaporation cooling: the current development and application[J]. Renewable and Sustainable Energy Reviews, 2016, 55: 614-628 doi: 10.1016/j.rser.2015.11.014 [5] 杜鹏, 周庆忠, 郑涵文, 等. 用于高密度集成微系统的微通道散热技术研究进展[J]. 微电子学与计算机, 2023, 40(1): 87-96DU Peng, ZHOU Qingzhong, ZHENG Hanwen, et a1. Research progress of microchannel cooling technology for high-density microsystems[J]. Microelectronics & Computer, 2023, 40(1): 87-96 [6] 高旭, 王学会, 雷刚, 等. 微重力流动沸腾气泡脱离机制[J]. 低温工程, 2015(2): 7-11,27 doi: 10.3969/j.issn.1000-6516.2015.02.002GAO Xu, WANG Xuehui, LEI Gang, et al. Bubble departure mechanism in microgravity flow boiling[J]. Cryogenics, 2015(2): 7-11,27 doi: 10.3969/j.issn.1000-6516.2015.02.002 [7] HONG S H, WANG J X, GAO Z J, et al. Review on state-of-the-art research in pool and flow boiling under microgravity[J]. Experimental Thermal and Fluid Science, 2023, 144: 110848 doi: 10.1016/j.expthermflusci.2023.110848 [8] LEE H, PARK I, MUDAWAR I, et al. Micro-channel evaporator for space applications–2. Assessment of predic-tive tools[J]. International Journal of Heat and Mass Transfer, 2014, 77: 1231-1249 doi: 10.1016/j.ijheatmasstransfer.2014.06.008 [9] HUANG Y P, YANG Q, ZHAO J Q, et al. Experimental study on flow boiling heat transfer characteristics of ammonia in microchannels[J]. Microgravity Science and Technology, 2020, 32(3): 477-492 doi: 10.1007/s12217-020-09786-z [10] VAN ERP R, SOLEIMANZADEH R, NELA L, et al. Co-designing electronics with microfluidics for more sustainable cooling[J]. Nature, 2020, 585(7824): 211-216 doi: 10.1038/s41586-020-2666-1 [11] 朱迅仪, 陈超伟, 张井志, 等. 歧管微通道热沉研究进展与展望[J]. 制冷学报, 2023, 44(4): 15-33 doi: 10.3969/j.issn.0253-4339.2023.04.015ZHU Xunyi, CHEN Chaowei, ZHANG Jingzhi, et al. Development and prospects of manifold microchannel heat sink research[J]. Journal of Refrigeration, 2023, 44(4): 15-33 doi: 10.3969/j.issn.0253-4339.2023.04.015 [12] LIN Y H, LUO Y, LI W, et al. Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements[J]. International Journal of Heat and Mass Transfer, 2021, 171: 121118 doi: 10.1016/j.ijheatmasstransfer.2021.121118 [13] WU Z H, XIAO W, SONG B. Efficient thermal management of high-power electronics via jet-enhanced HU-type manifold microchannel[J]. International Journal of Heat and Mass Transfer, 2024, 221: 125113 doi: 10.1016/j.ijheatmasstransfer.2023.125113 [14] JUNG K W, KHARANGATE C R, LEE H, et al. Embedded cooling with 3D manifold for vehicle power electronics application: single-phase thermal-fluid performance[J]. International Journal of Heat and Mass Transfer, 2019, 130: 1108-1119 doi: 10.1016/j.ijheatmasstransfer.2018.10.108 [15] PALKO J W, LEE H, ZHANG C, et al. Extreme two-phase cooling from laser-etched diamond and conformal, template-fabricated microporous copper[J]. Advanced Functional Materials, 2017, 27(45): 1703265 doi: 10.1002/adfm.201703265 [16] TANG K, LIN G P, GUO Y D, et al. Thermal-hydraulic characterization of manifold microchannel heat sink with diverging channels and uniform heating[J]. Thermal Science and Engineering Progress, 2023, 46: 102235 doi: 10.1016/j.tsep.2023.102235 [17] 汤凯, 黄岩培, 郭元东, 等. 局部热点射流式微通道流动沸腾实验研究[J]. 工程热物理学报, 2024, 45(6): 1743-1748TANG Kai, HUANG Yanpei, GUO Yuandong, et al. Experimental study on localized hot spot jet impingement flow boiling[J]. Journal of Engineering Thermophysics, 2024, 45(6): 1743-1748 [18] KALANI A, KANDLIKAR S G. Flow patterns and heat transfer mechanisms during flow boiling over open micro-channels in tapered manifold (OMM)[J]. International Journal of Heat and Mass Transfer, 2015, 89: 494-504 doi: 10.1016/j.ijheatmasstransfer.2015.05.070 [19] 杨涵. 微通道流动沸腾传热特性及可视化实验研究[D]. 大连: 大连理工大学, 2022YANG Han. Experimental Study of Flow Boiling Heat Transfer Characteristics and Visualization in Micro-Channels[D]. Dalian: Dalian University of Technology, 2022 [20] HUANG Y P, MIAO J Y, NIU Z T, et al. Experimental investigation on heat transfer and pressure drop characteri-stics of confined jet impingement boiling on hybrid-structured surface[J]. Applied Thermal Engineering, 2023, 218: 119320 doi: 10.1016/j.applthermaleng.2022.119320 [21] TANG K, HUANG Y P, LIN G P, et al. Thermal-hydraulic performance of ammonia in manifold microchannel heat sink[J]. Applied Thermal Engineering, 2023, 232: 121000 doi: 10.1016/j.applthermaleng.2023.121000 -

-

乔通 男, 2001年5月生于湖南省邵阳市. 现就读于北京航空航天大学航空科学与工程学院, 硕士研究生, 主要研究方向为歧管微通道换热、流动沸腾传热实验研究. E-mail:

乔通 男, 2001年5月生于湖南省邵阳市. 现就读于北京航空航天大学航空科学与工程学院, 硕士研究生, 主要研究方向为歧管微通道换热、流动沸腾传热实验研究. E-mail:

下载:

下载: