Research Progress of Electrocaloric Cooling Technology and Prospect for Space Applications

-

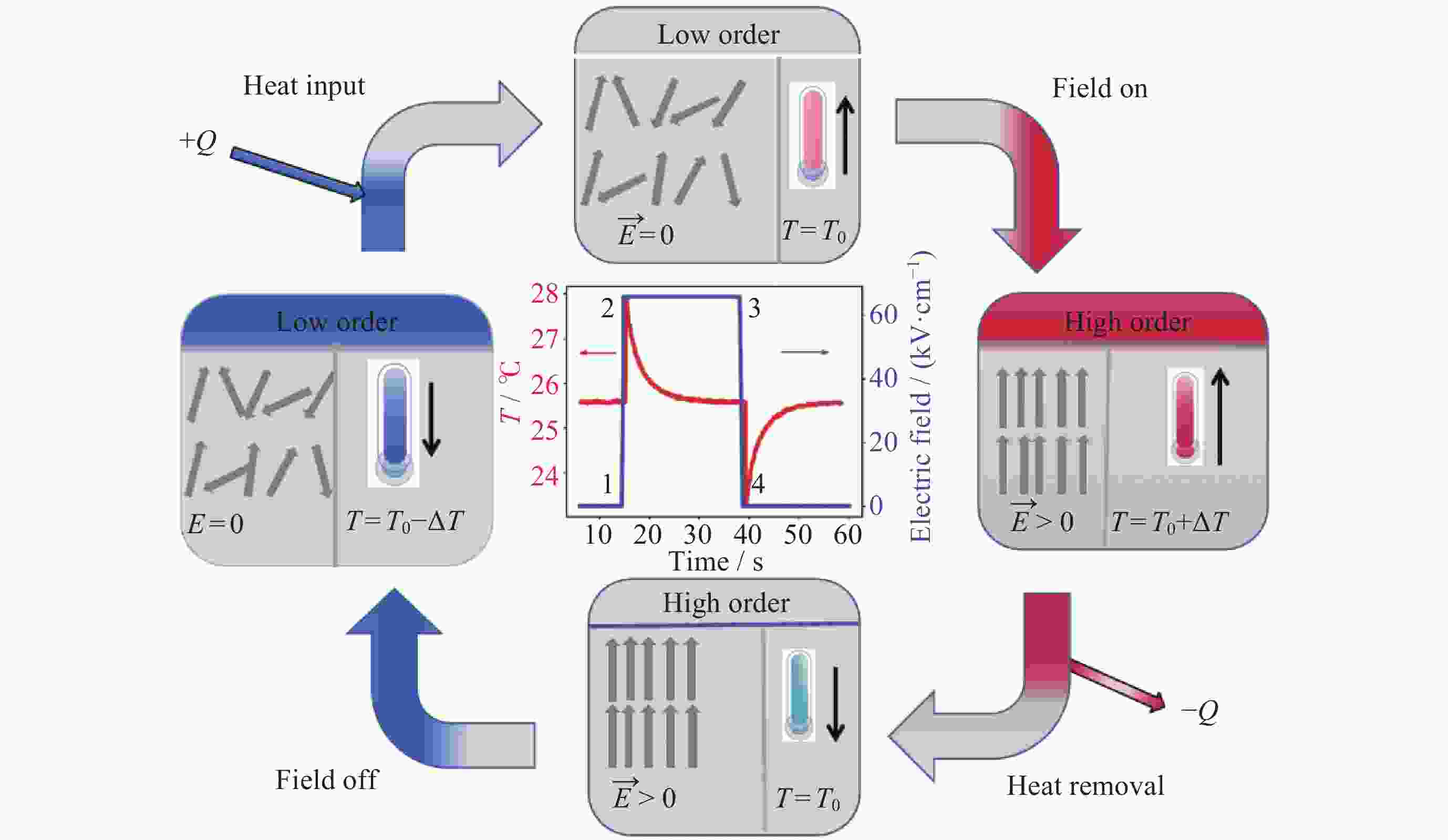

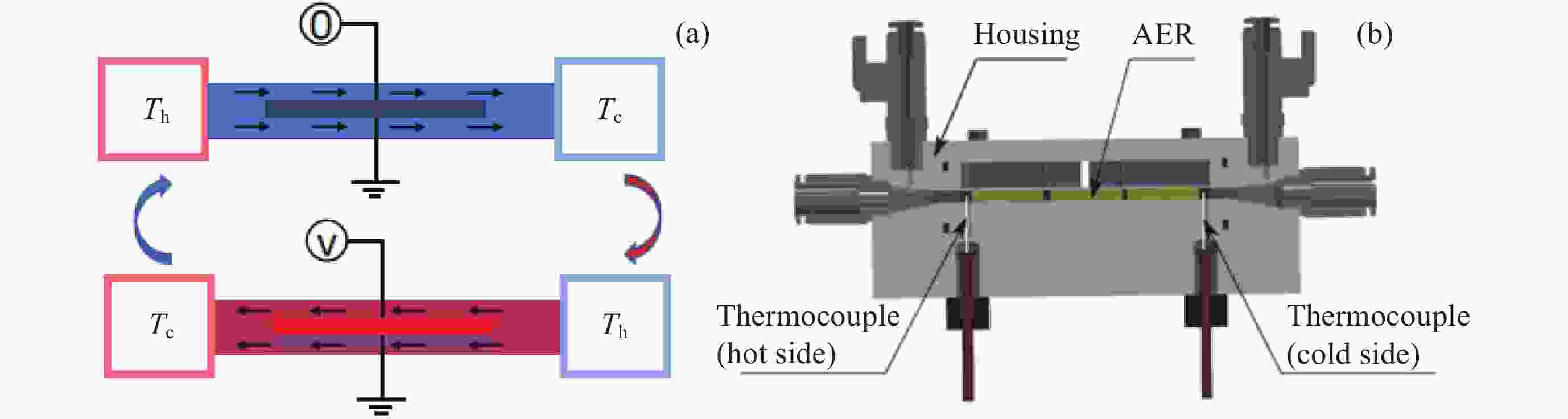

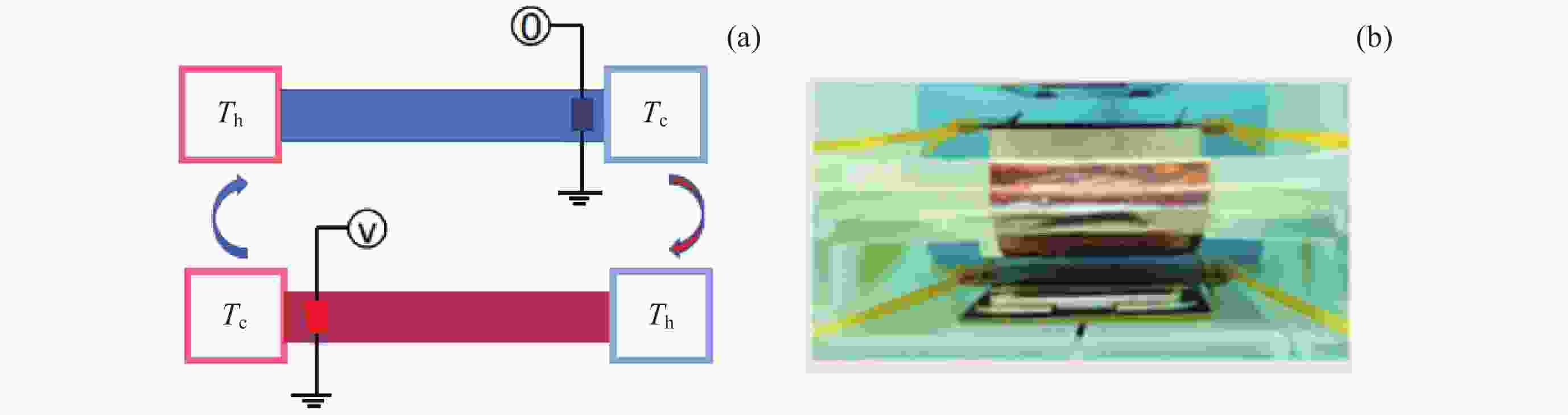

摘要: 电卡制冷技术是一种新型的固态制冷技术, 利用电卡材料在加电和去电过程的熵变实现制冷循环, 具有高能效、轻量化、无制冷剂泄漏特点, 在航天冷藏箱、空间可穿戴设备等领域具有巨大的应用前景. 目前, 空间热电制冷技术存在电耗大、制冷系数低等问题, 限制了该技术未来在航天工程中的应用. 本文从电卡材料性能、电卡冷热分离方法及电卡制冷器件三方面进行回顾和分析, 介绍了电卡组分、形态、制备工艺、可靠性和稳定性方面的研究进展, 总结了电卡制冷原理以及主动式和被动式的冷热分离方法, 归纳了往复单级和往复多级电卡器件的工作原理. 最后, 展望了电卡制冷技术未来在空间科学领域的发展方向.Abstract: Electric card refrigeration technology is a new type of solid-state refrigeration technology that utilizes the entropy change of electrocaloric materials during the process of charging and discharging to achieve a refrigeration cycle. It has the characteristics of high energy efficiency, light weight, and no refrigerant leakage, so that it has great application prospects in fields such as aerospace refrigerators and space wearable devices. Until now, space thermoelectric cooling technology has many problems such as high-power consumption and low Coefficient of Performance (COP), which limit its application in future aerospace engineering. This article reviews and analyzes the material properties, cold and hot separation methods, and electrocaloric refrigeration devices. It introduces the research progress in the electrocaloric composition, morphology, preparation process, feasibility, and stability, summarizes the electrocaloric refrigeration principle, as well as cold and hot separation methods of active and passive ways, and summarizes the working principles of reciprocating single-stage and reciprocating cascade electrocaloric refrigeration devices. Finally, the future development direction of electrocaloric cooling technology in the field of space science was discussed.

-

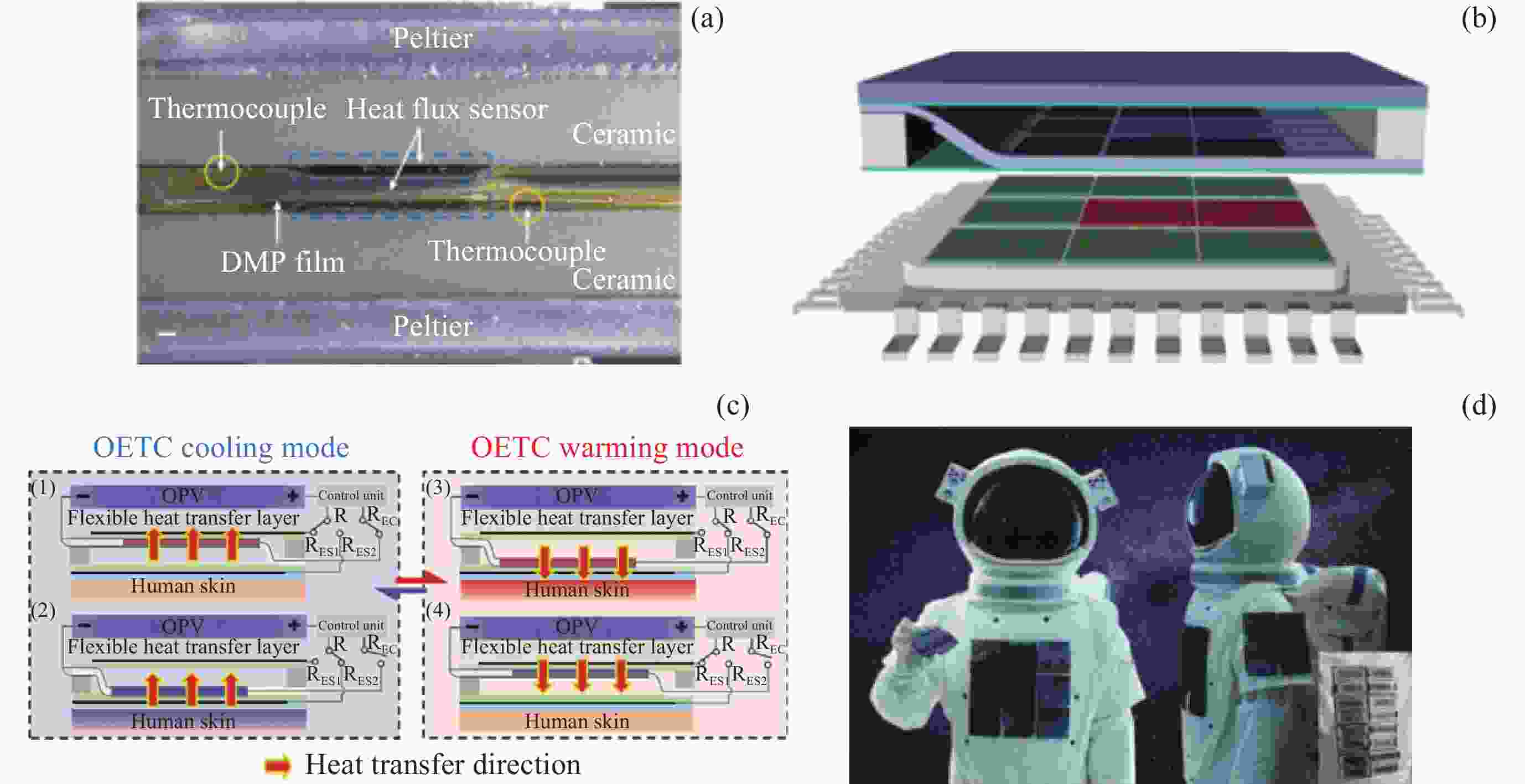

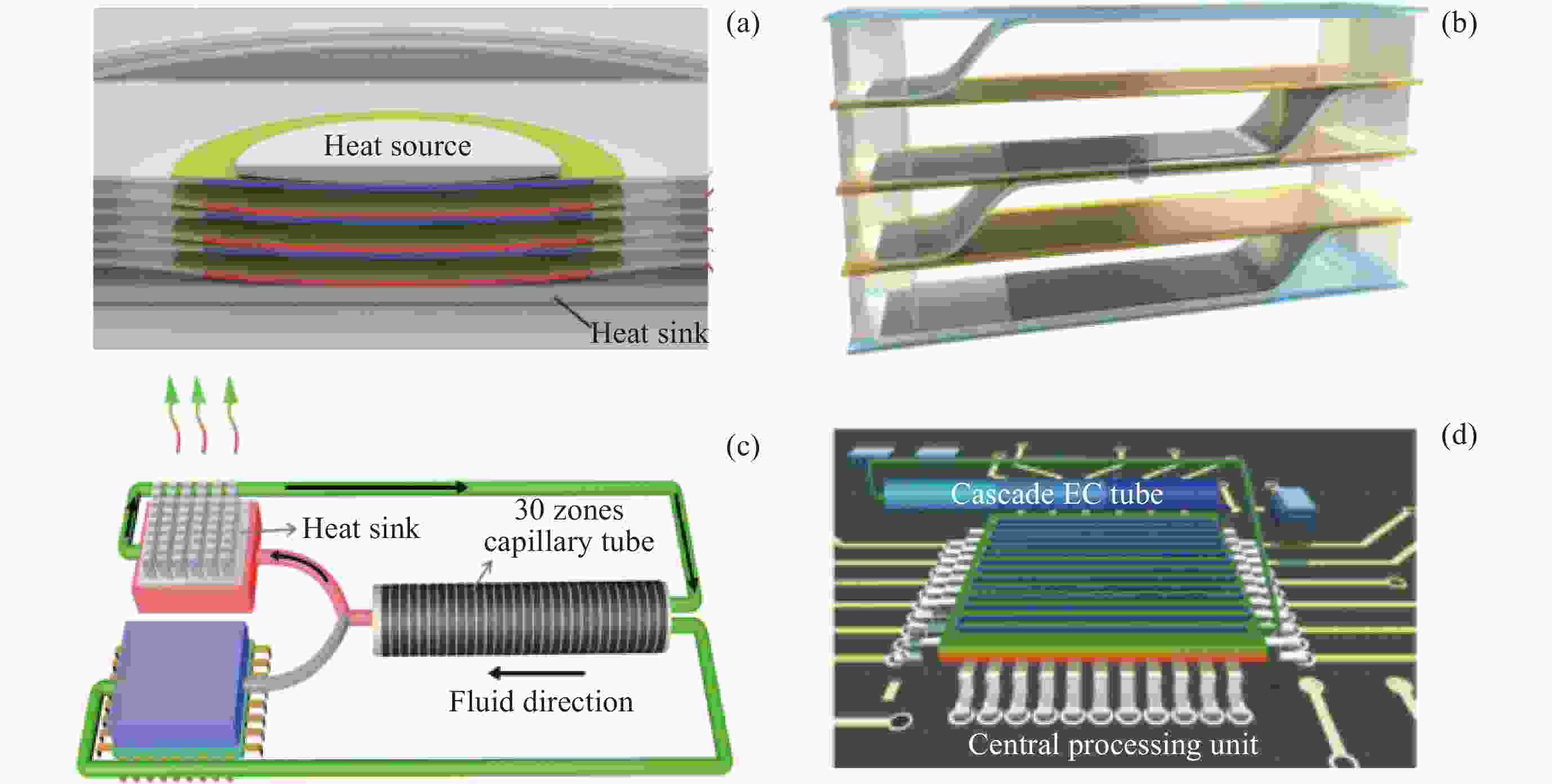

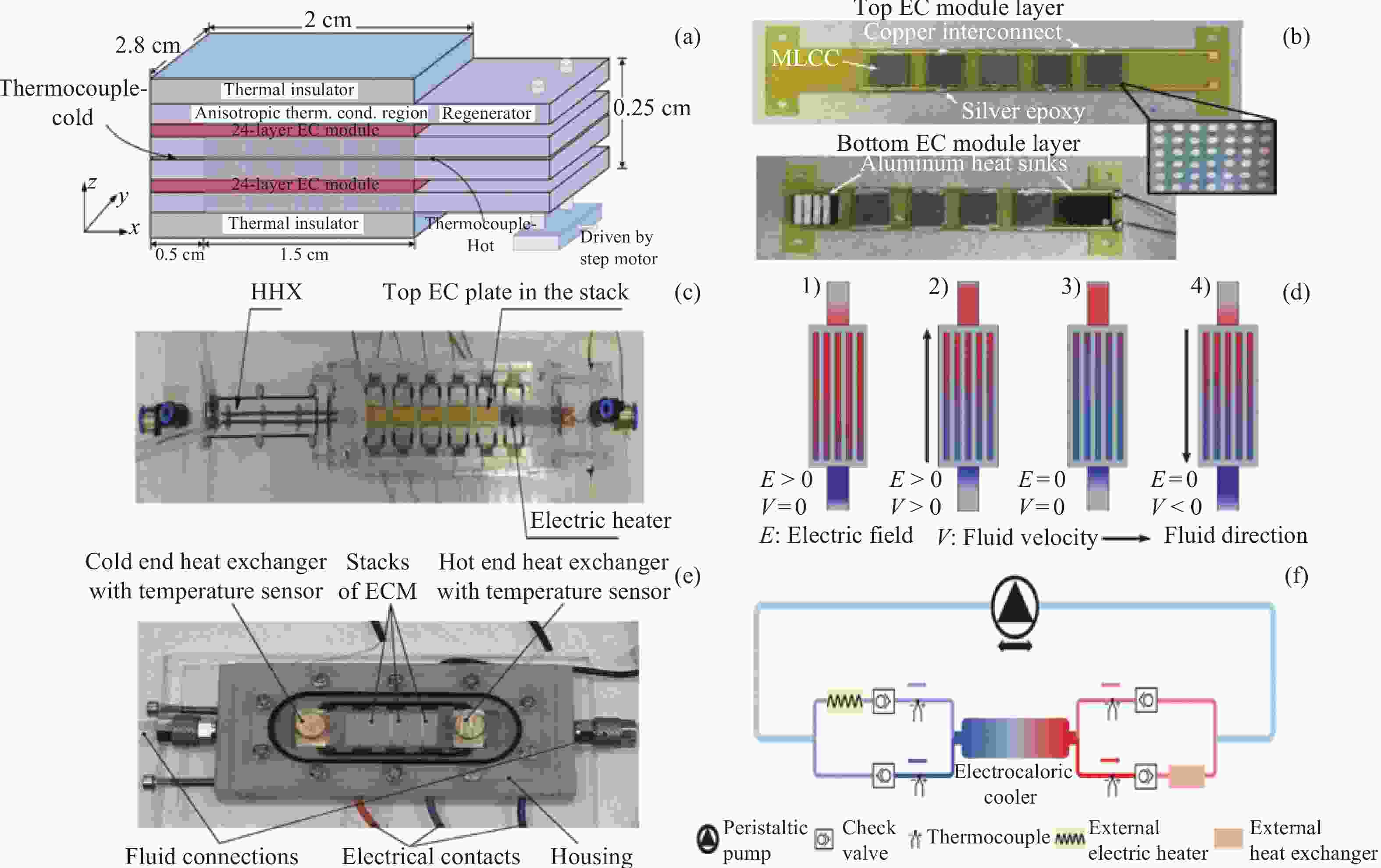

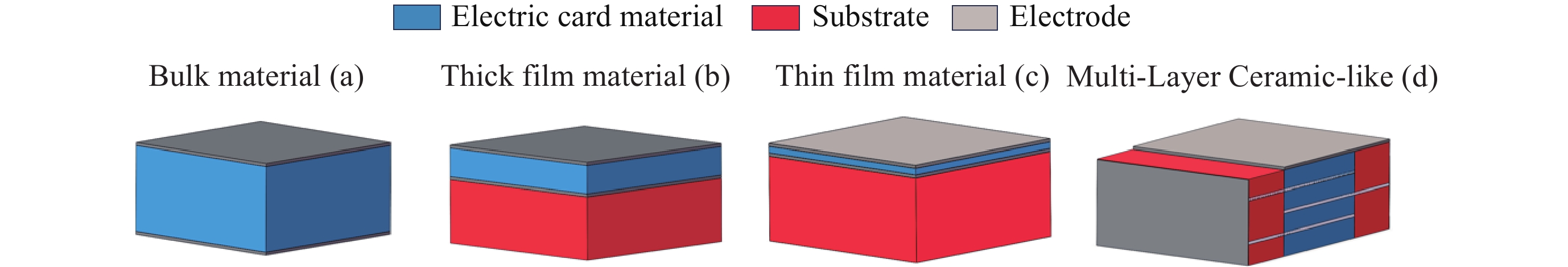

图 8 往复多级回热制冷器件. (a)高分子材料主动回热制冷器件, (b) PST多层电容制冷器件, (c) PMN-100xPT制冷器件, (d) PST多层平板式制冷器件, (e) PMN-8 PT制冷器件, (f)双回路主动回热制冷器件

Figure 8. Reciprocating cascade regenerative refrigeration device. (a) Polymer material active regenerative refrigeration device, (b) PST-based multi-layer device, (c) PMN-100xPT device, (d) PST-based cascade flat device, (e) PMN-8 PT-based device, (f) double-circuit active regenerative device

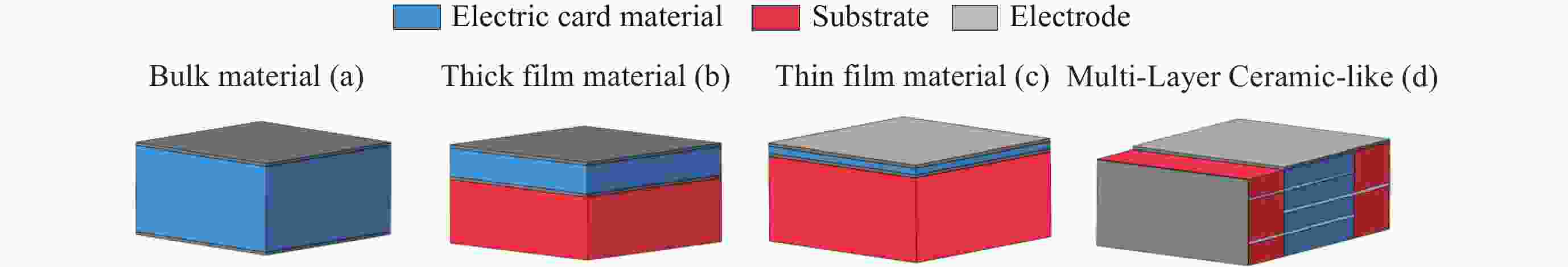

表 1 不同组分电卡材料的组成、形态、测试条件及其性能参数

Table 1. Composition, configuration, testing conditions, and property parameters of different types of electrocaloric materials

材料 形态 测试

温度T/K温变

ΔT/K电场强度E/

(kV·cm–1)电热强度(ΔT/

ΔE)/(K·cm·kV–1)熵变ΔS/

(J·kg–1·K–1)无机

材料PMN-30 PT[10] 块体 418 2.6 90 0.289 - (Pb0.97La0.02)(Zr0.80Sn0.14Ti0.06)O3[15] 块体 323 –14.1 110 0.128 –13.5 Pb 0.8 Ba0.2ZrO3[11] 薄膜 290 45 598 0.075 46.9 PbZr0.95Ti0.05O3[17] 薄膜 495 12 480 0.025 8 Ba(Zr0.20Ti0.80)O3−Ba(Sn0.11 Ti0.89)O3[16] 厚膜 298 5.2 330 0.016 6.9 BaZr0.2Ti0.8O3[25] 厚膜 - –7 195 0.036 –17.16 PbSc0.5Ta0.5O3[18] MLC 330 –6.1 290 0.021 –53 有机

材料P(VDF-TrFE) 68%/32%[12] 厚膜 306 20 160 0.125 95 P(VDF-TrFE-CFE)

59.2%/33.6%/7.2%[26]厚膜 303 14.8 150 0.987 95 复合

材料P(VDF-TrFE-CFE)/PBZ 97%/3%[14] 薄膜 243 13.99 150 0.093 52.7 P(VDF-TrFE-CFE)/PMN-PT[27] 薄膜 303 31 180 0.171 - -

[1] HU H H, JU Y W, YU J C, et al. Highly stabilized and efficient thermoelectric copper selenide[J]. Nature Materials, 2024, 23(4): 527-534 [2] LI P, QIU P F, XU Q, et al. Colossal Nernst power factor in topological semimetal NbSb2[J]. Nature Communications, 2022, 13(1): 7612 [3] ZHANG S, DELIYORE-RAMÍREZ J, DENG S, et al. Highly reversible extrinsic electrocaloric effects over a wide temperature range in epitaxially strained SrTiO3 films[J]. Nature Materials, 2024, 23(5): 639-647 [4] QIAN S X, CATALINI D, MUEHLBAUER J, et al. High-performance multimode elastocaloric cooling system[J]. Science, 2023, 380(6646): 722-727 [5] 新黄河. 七次上太空的航天冰箱,为何只有海尔能造[EB/OL]. [2022-04-16]. https://www.toutiao.com/article/7087208257655210530/?wid=1747802224560 [6] LI C Y, CAI Y C, XIE Y F, et al. Enhanced dielectric/ferroelectric properties of P(VDF-TrFE) composite films with organic perovskite ferroelectrics[J]. Applied Physics Express, 2023, 16(3): 031008 [7] WANG D, CHEN X, YUAN G L, et al. Toward artificial intelligent self-cooling electronic skins: large electrocaloric effect in all-inorganic flexible thin films at room temperature[J]. Journal of Materiomics, 2019, 5(1): 66-72 [8] 白洋, 李建厅, 秦士强, 等. 面向高效固态制冷应用的铁电陶瓷材料[J]. 现代技术陶瓷, 2018, 39(6): 369-389BAI Yang, LI Jianting, QIN Shiqiang, et al. Ferroelectric ceramics for high-efficient solid-state refrigeration[J]. Advanced Ceramics, 2018, 39(6): 369-389 [9] SUN H C, MENG Y Z, HAN F F, et al. Simultaneously achieved large electrocaloric effect and broad working temperature range in transparent Sm-doped 0.88Pb(Mg1/3Nb2/3)O3-0.12PbTiO3 ceramics at low electric field[J]. Ceramics International, 2024, 50(11): 19237-19244 [10] ROŽIČ B, KOSEC M, URŠIČ H, et al. Influence of the critical point on the electrocaloric response of relaxor ferroelectrics[J]. Journal of Applied Physics, 2011, 110(6): 064118 [11] PENG B L, FAN H Q, ZHANG Q. A giant electrocaloric effect in nanoscale antiferroelectric and ferroelectric phases coexisting in a relaxor Pb0.8Ba0.2ZrO3 thin film at room temperature[J]. Advanced Functional Materials, 2013, 23(23): 2987-2992 [12] LU S G, ROŽIČ B, ZHANG Q M, et al. Organic and inorganic relaxor ferroelectrics with giant electrocaloric effect[J]. Applied Physics Letters, 2010, 97(16): 162904 [13] 李子超, 施骏业, 陈江平, 等. 电卡制冷材料与系统发展现状与展望[J]. 制冷学报, 2021, 42(1): 1-13LI Zichao, SHI Junye, CHEN Jiangping, et al. Electrocaloric cooling materials and systems: a review and perspective[J]. Journal of Refrigeration, 2021, 42(1): 1-13 [14] QIAN G M, ZHU K J, LI X, et al. The electrocaloric effect of PBZ/PVDF flexible composite film near room temperature[J]. Journal of Materials Science: Materials in Electronics, 2021, 32(12): 12001-12016 [15] ZHUO F P, LI Q, GAO J H, et al. Giant negative electrocaloric effect in (Pb, La)(Zr, Sn, Ti)O3 antiferroelectrics near room temperature[J]. ACS Applied Materials :Times New Roman;">& Interfaces, 2018, 10(14): 11747-11755 [16] LI J L, CHANG Y F, YANG S, et al. Lead-free bilayer thick films with giant electrocaloric effect near room temperature[J]. ACS Applied Materials :Times New Roman;">& Interfaces, 2019, 11(26): 23346-23352 [17] MISCHENKO A S, ZHANG Q, SCOTT J F, et al. Giant electrocaloric effect in thin-film PbZr0.95Ti0.05O3[J]. Science, 2006, 311(5765): 1270-1271 [18] NAIR B, USUI T, CROSSLEY S, et al. Large electrocaloric effects in oxide multilayer capacitors over a wide temperature range[J]. Nature, 2019, 575(7783): 468-472 [19] ZHENG S Y, DU F H, ZHENG L R, et al. Colossal electrocaloric effect in an interface-augmented ferroelectric polymer[J]. Science, 2023, 382(6674): 1020-1026 [20] HUANG Y F, GU T, RUI G C, et al. A relaxor ferroelectric polymer with an ultrahigh dielectric constant largely promotes the dissociation of lithium salts to achieve high ionic conductivity[J]. Energy :Times New Roman;">& Environmental Science, 2021, 14(11): 6021-6029 [21] SADL M, PRAH U, KOVACOVA V, et al. Multifunctional flexible ferroelectric thick-film structures with energy storage, piezoelectric and electrocaloric performance[J]. Journal of Materials Chemistry C, 2023, 11(29): 10058-10068 doi: 10.1039/D3TC01555F [22] LI X Y, YANG J L, PAN X H, et al. New soft actuating way by rapidly temperature change of electrocaloric effect[J]. ACS Applied Materials :Times New Roman;">& Interfaces, 2023, 15(24): 29449-29456 [23] LU S J, CHEN G R, ZHANG Y C, et al. Electrocaloric effect in lead-free 0.5Ba(Zr0.2Ti0.8) O3-0.5(Ba0.7Ca0.3) TiO3 ceramic measured by direct and indirect methods[J]. Ceramics International, 2018, 44(17): 21950-21955 [24] QIAN X S, HAN D L, ZHENG L R, et al. High-entropy polymer produces a giant electrocaloric effect at low fields[J]. Nature, 2021, 600(7890): 664-669 [25] YE H J, QIAN X S, JEONG D Y, et al. Giant electrocaloric effect in BaZr0.2Ti0.8O3 thick film[J]. Applied Physics Letters, 2014, 105(15): 152908 [26] LI X Y, QIAN X S, LU S G, et al. Tunable temperature dependence of electrocaloric effect in ferroelectric relaxor poly (vinylidene fluoride-trifluoroethylene-chlorofluoroethylene terpolymer[J]. Applied Physics Letters, 2011, 99(5): 052907 [27] LI Q, ZHANG G Z, ZHANG X S, et al. Relaxor ferroelectric-based electrocaloric polymer nanocomposites with a broad operating temperature range and high cooling energy[J]. Advanced Materials, 2015, 27(13): 2236-2241 [28] 赵建福, 王双峰, 刘强, 等. 中国微重力科学研究回顾与展望[J]. 空间科学学报, 2021, 41(1): 34-45 doi: 10.11728/cjss2021.01.034ZHAO Jianfu, WANG Shuangfeng, LIU Qiang, et al. Retrospect and perspective on microgravity science in China[J]. Chinese Journal of Space Science, 2021, 41(1): 34-45 doi: 10.11728/cjss2021.01.034 [29] MENG Y, PU J H, PEI Q B. Electrocaloric cooling over high device temperature span[J]. Joule, 2021, 5(4): 780-793 doi: 10.1016/j.joule.2020.12.018 [30] SINYAVSKY Y V, PASHKOV N D, GOROVOY Y M, et al. The optical ferroelectric ceramic as working body for electrocaloric refrigeration[J]. Ferroelectrics, 1989, 90(1): 213-217 [31] PLAZNIK U, KITANOVSKI A, ROŽIČ B, et al. Bulk relaxor ferroelectric ceramics as a working body for an electrocaloric cooling device[J]. Applied Physics Letters, 2015, 106(4): 043903 [32] JIA Y B, JU Y S. A solid-state refrigerator based on the electrocaloric effect[J]. Applied Physics Letters, 2012, 100(24): 242901 [33] LI M D, SHEN X Q, CHEN X, et al. Thermal management of chips by a device prototype using synergistic effects of 3-D heat-conductive network and electrocaloric refrigeration[J]. Nature Communications, 2022, 13(1): 5849 [34] HAN D L, ZHANG Y J, HUANG C L, et al. Self-oscillating polymeric refrigerator with high energy efficiency[J]. Nature, 2024, 629(8014): 1041-1046 [35] MA R J, ZHANG Z Y, TONG K, et al. Highly efficient electrocaloric cooling with electrostatic actuation[J]. Science, 2017, 357(6356): 1130-1134 [36] BAI P J, ZHANG Q, CUI H, et al. An active pixel-matrix electrocaloric device for targeted and differential thermal management[J]. Advanced Materials, 2023, 35(15): 2209181 [37] WANG Z Y, BO Y W, BAI P J, et al. Self-sustaining personal all-day thermoregulatory clothing using only sunlight[J]. Science, 2023, 382(6676): 1291-1296 [38] WU H X, ZHU Y, YAN W Z, et al. A self-regenerative heat pump based on a dual-functional relaxor ferroelectric polymer[J]. Science, 2024, 386(6721): 546-551 [39] MENG Y, ZHANG Z Y, WU H X, et al. A cascade electrocaloric cooling device for large temperature lift[J]. Nature Energy, 2020, 5(12): 996-1002 [40] CUI H, ZHANG Q, BO Y W, et al. Flexible microfluidic electrocaloric cooling capillary tube with giant specific device cooling power density[J]. Joule, 2022, 6(1): 258-268 [41] BAI P J, CUI H, ZHANG D, et al. A highly efficient cascade electrocaloric cooling tube with enhanced temperature change by sawtooth voltage[J]. Next Materials, 2023, 1(1): 100001 [42] GU H M, QIAN X S, LI X Y, et al. A chip scale electrocaloric effect based cooling device[J]. Applied Physics Letters, 2013, 102(12): 122904 doi: 10.1063/1.4799283 [43] WANG Y D, ZHANG Z Y, USUI T, et al. A high-performance solid-state electrocaloric cooling system[J]. Science, 2020, 370(6512): 129-133 [44] PLAZNIK U, VRABELJ M, KUTNJAK Z, et al. Numerical modelling and experimental validation of a regenerative electrocaloric cooler[J]. International Journal of Refrigeration, 2019, 98: 139-149 [45] TORELLÓ A, LHERITIER P, USUI T, et al. Giant temperature span in electrocaloric regenerator[J]. Science, 2020, 370(6512): 125-129 doi: 10.1126/science.abb8045 [46] BLUMENTHAL P, RAATZ A. Design methodology for electrocaloric cooling systems[J]. Energy Technology, 2018, 6(8): 1560-1566 doi: 10.1002/ente.201800139 [47] LI J N, TORELLÓ A, KOVACOVA V, et al. High cooling performance in a double-loop electrocaloric heat pump[J]. Science, 2023, 382(6672): 801-805 -

-

常启泰 男, 1999年3月出生于吉林省榆树市, 现为桂林电子科技大学机械工程专业在读研究生, 主要研究方向为电卡制冷实验研究. E-mail:

常启泰 男, 1999年3月出生于吉林省榆树市, 现为桂林电子科技大学机械工程专业在读研究生, 主要研究方向为电卡制冷实验研究. E-mail:

下载:

下载: