Research and Prospect of In-situ Construction Materials on Mars

-

摘要: 火星风化层作为一种重要的原位自然资源, 在火星基础设施建设上具有重要作用. 基于与地球上不同的火星极端环境与火壤特殊性质, 系统研究了火星原位建造材料的物理特征与机械性质, 重点分析了火壤类混凝土材料(具体包括含硫混凝土、聚合物混凝土、地聚物混凝土与水凝胶基混凝土)、火壤熔融与烧结原位固化材料两个方面的最新研究进展. 尽管目前火星原位建造材料的研究已取得一定成果, 但仍面临诸如聚合物混凝土原位制备困难、熔融与烧结过程能耗较大, 以及在火星环境下建造材料服役性能不足等局限问题. 根据火星原位建造材料在未来的发展方向, 研究结果旨在积极推进对火星原位建造材料的深入研究, 为实现火星原位建造提供借鉴与参考.Abstract: Martian regolith has gradually become a consensus as an important in-situ natural resource for building habitats and infrastructure on Mars. As more and more research focusing on in-situ utilization of Martian regolith, this article provides a comprehensive review of construction materials based on Martian regolith. However, it is necessary to consider the vastly different environmental conditions on Mars compared to Earth, such as low gravity, near vacuum, large temperature differences, cosmic ray radiation and so on. Similarly, due to the unique chemical composition, particle size, porosity, as well as thermal and mechanical properties of Martian regolith, it also brings several certain difficulties for in-situ production of construction materials on Mars. As a result, based on the extreme environment of Mars and the special properties of Martian regolith, this article provides a detailed overview of the preparation process and physical and mechanical characteristics of in-situ construction materials. Then, the research progress in two aspects of various Martian regolith-based concrete materials (including sulfur concrete, polymer concrete, geopolymer concrete, hydrogel-based concrete), Martian regolith-based melting and sintering materials is further emphasized. Moreover, this article systematically compares the preparation conditions and in-situ utilization rates of each construction material and analyzes both the advantages and weakness of their preparation processes in the special Martian environment. Finally, the problems and limitations of the above-mentioned materials in Martian in-situ construction are pointed out, including difficulties in production of polymer concrete, high energy consumption during melting and sintering processes, and insufficient service performance of construction materials in Martian environments. Accordingly, in order to provide useful references for the realization of in-situ construction on Mars in the future, the development direction of construction materials has been proposed in three aspects, which are the improved methods of anhydrous concrete represented by polymer concrete, optimization of melting and sintering processes and development of new materials suitably adapted to the environment.

-

Key words:

- Martian regolith /

- In-situ resources /

- Concrete /

- Melting /

- Sintering

-

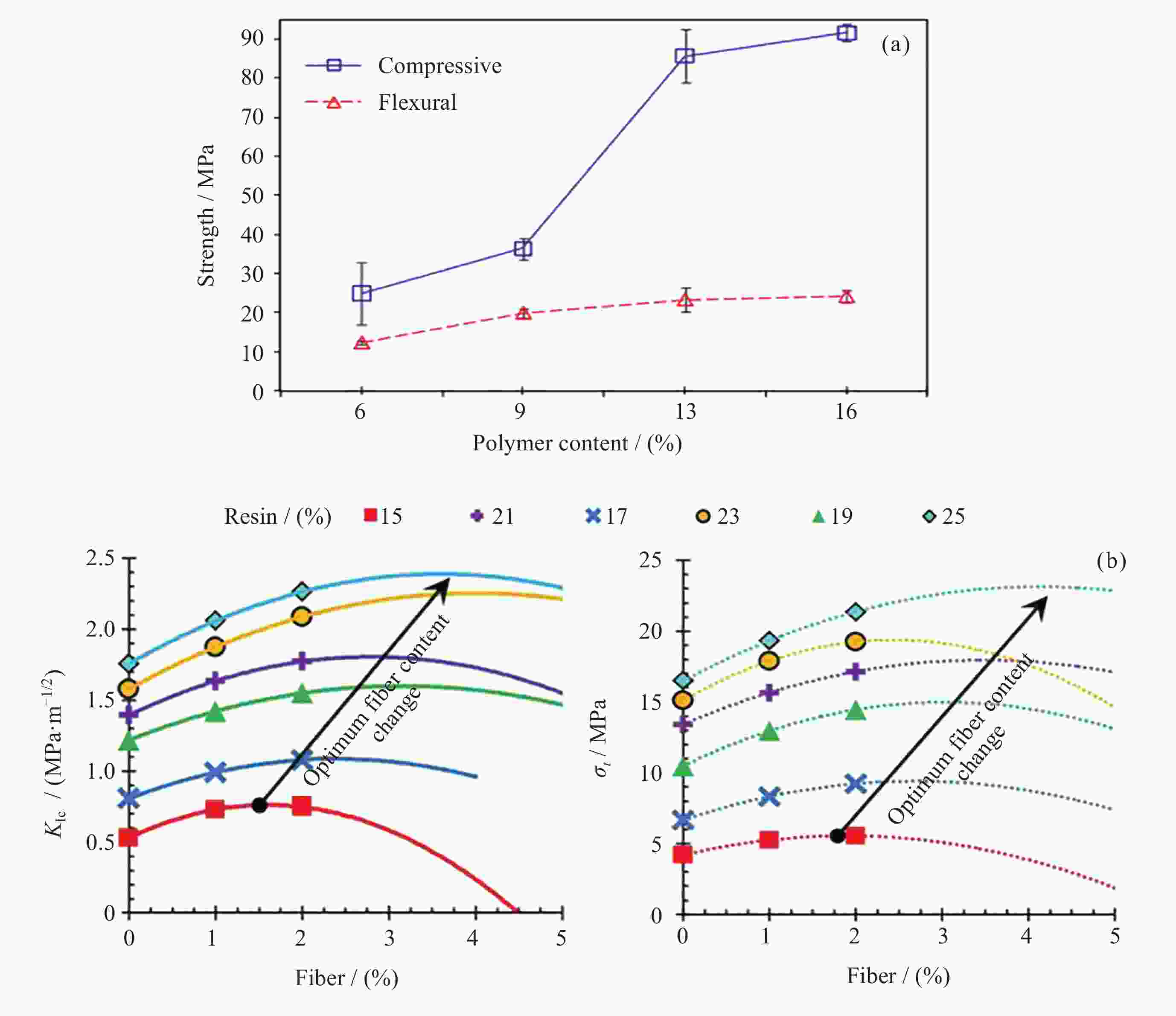

图 4 聚合物含量和添加纤维对地聚合物混凝土性能的影响. (a) 聚合物含量对环氧聚合物混凝土抗压强度和抗弯强度的影响, (b)断裂韧性和抗拉强度由于在不同树脂含量中添加纤维引起的变化, 以及树脂含量变化引起的最佳纤维含量变化趋势

Figure 4. Effect of polymer content and added fiber on properties of geopolymer concrete. (a) Effect of polymer content on the compressive and flexural strength of epoxy polymer concretes, (b) changes in fracture toughness and tensile strength due to the addition of fibers to the resin content, and trends in optimal fiber content due to changes in resin content

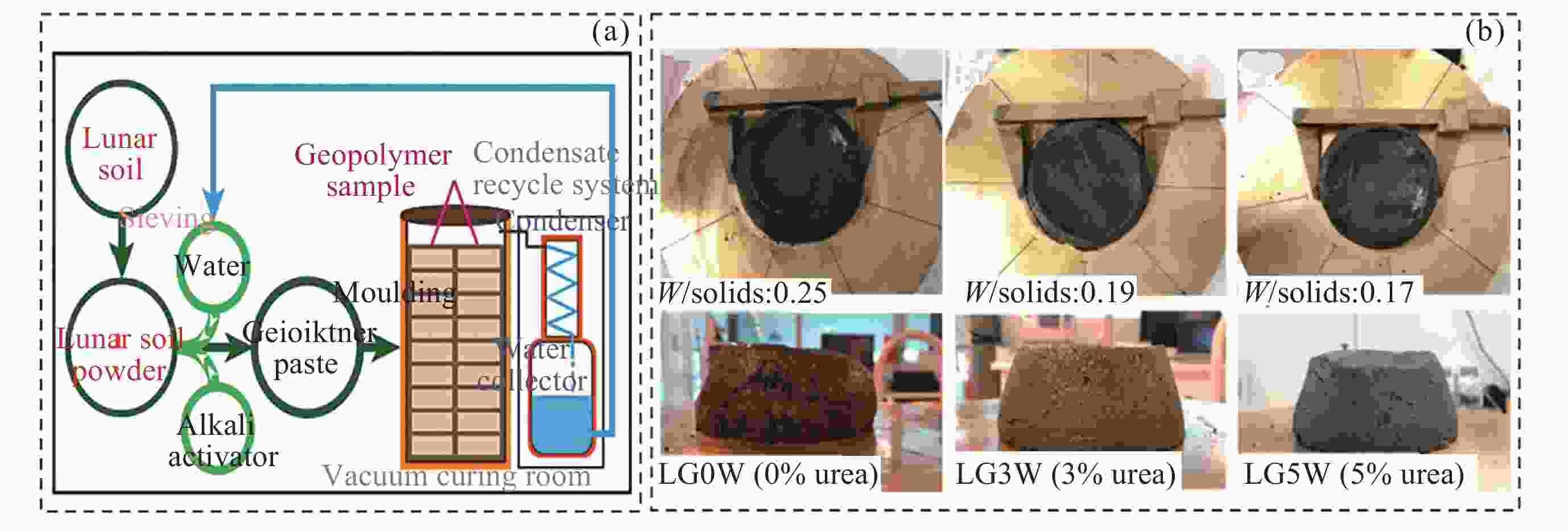

图 5 减少地聚合物混凝土制备用水量的两种措施. (a)制备地质聚合物的样品和假设的水循环装置工艺流程, (b)地质聚合物的流动性的小型坍落度测量

Figure 5. Two measures to reduce water consumption in preparation of geopolymer concrete. (a) Process flow chart for the preparation of a geopolymer sample and a hypothetical water-recycling device, (b) mini slump measurements of the flowability of the geopolymers

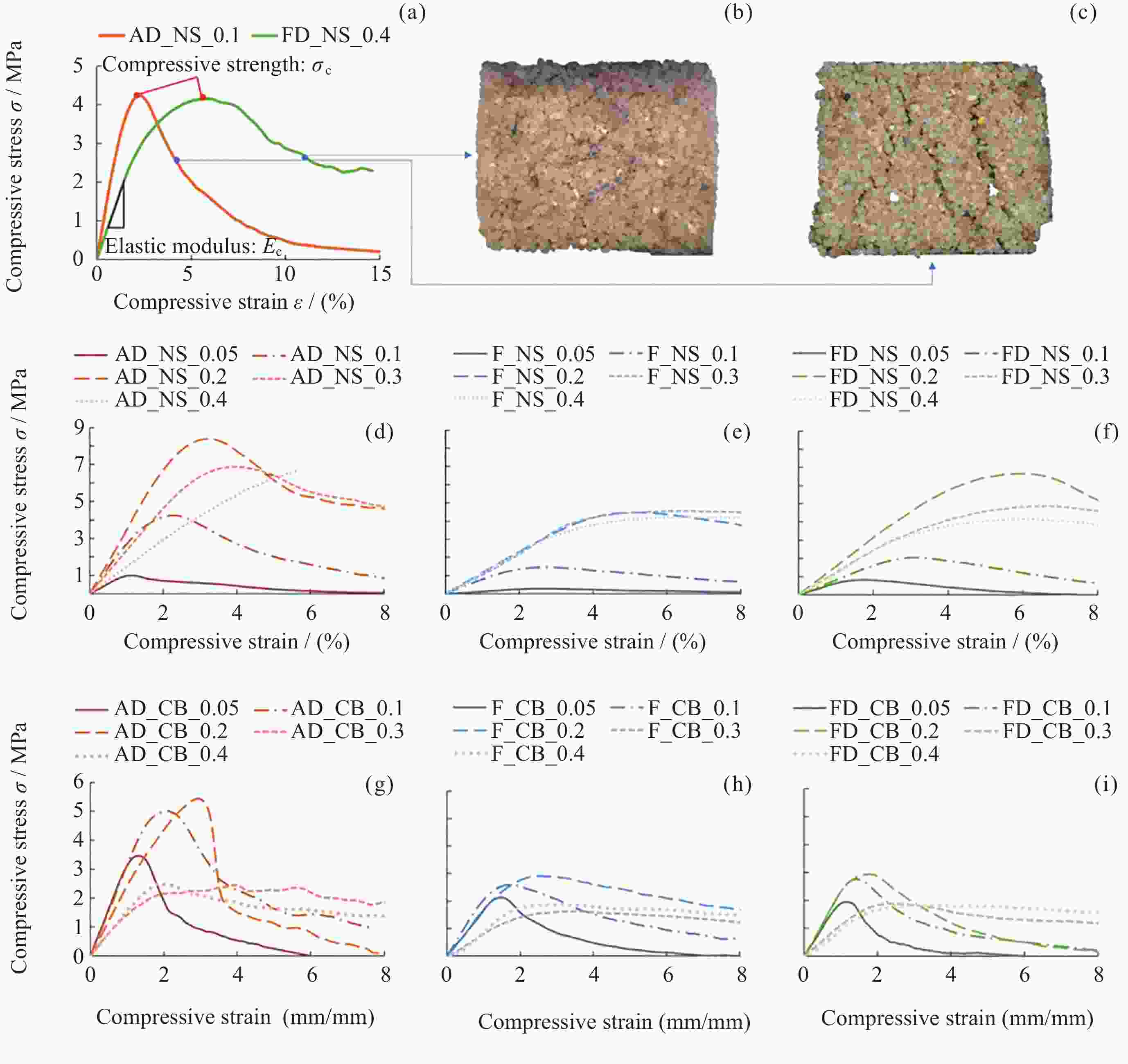

图 6 HBC的机械性能测试. (a)立方体的典型压应力与应变曲线, (b)(c)立方体的破坏模式. 以天然砂(NS)为基础的HBC的应力应变曲线: (d)风干固化, (e)冷冻固化, (f)冷冻干燥固化. 以陶瓷(CB)为基础的HBC的应力应变曲线: (g)风干固化, (h)冷冻固化, (i)冷冻干燥固化

Figure 6. Mechanical properties test of HBC. (a) Typical compressive stress vs. strain curves of the cube, (b)(c) failure mode of the cube. Compressive stress vs. strain curve of Natural Sand (NS)-based HBC: (d) Air Drying (AD)-cured, (e) Freezing (F)-cured, (f) Freeze-Drying (FD)-cured. Compressive stress vs. strain curve of the Ceramic Bead (CB)-based HBC: (g) Air Drying (AD)-cured, (h) Freezing (F)-cured, (i) Freeze-Drying (FD)-cured

表 1 地球、月球和火星之间的差异

Table 1. Differences between Earth, Moon and Mars

参数 地球 月球 火星 质量/kg 5.9×1024 7.2×1022 6.4×1023 直径/km 12742 3474 6779 表面积/km2 5.11×108 37.9×106 144.8×106 表面重力/(m·s–2) 9.81 1.62 3.71 地震能量/(J·a–1) 10171018 1010~1014 — 大气压/kPa 101.3 3×10–13 0.7 主要组成 N2, O2 — CO2, Ar 表面极端温度/℃ –89.2~56.9 –195~120 –143~35 昼夜周期/h 23.9 656 24.7 轨道周期/d 365.3 29.5 687 年平均辐射/mSv 2.4 380 100 与地球的距离/km — 384.4×103 54.6×106 表 2 制备以火壤为原料的不同建材的比较

Table 2. Comparison of different building materials prepared based on Mars regolith

-

[1] MUSK E. Making life multi-planetary[J]. New Space, 2018, 6(1): 2-11 doi: 10.1089/space.2018.29013.emu [2] ZHENG W, HSU H, ZHONG M, et al. China’s first-phase Mars exploration program: Yinghuo-1 orbiter[J]. Planetary and Space Science, 2013, 86: 155-159 doi: 10.1016/j.pss.2011.02.008 [3] VADIM Z, VLADIMIR P. Russian nuclear rocket engine design for mars exploration[J]. Tsinghua Science and Technology, 2007, 12(3): 256-260 doi: 10.1016/S1007-0214(07)70038-X [4] SCOTT A N, OZE C. Constructing mars: concrete and energy production from serpentinization products[J]. Earth and Space Science, 2018, 5(8): 364-370 doi: 10.1029/2017EA000353 [5] BENAROYA H. Lunar habitats: a brief overview of issues and concepts[J]. REACH, 2017, 7-8: 14-33 doi: 10.1016/j.reach.2018.08.002 [6] CUCINOTTA F A, HU S W, SCHWADRON N A, et al. Space radiation risk limits and Earth-Moon-Mars environmental models[J]. Space Weather, 2010, 8(12): S00E09 [7] OBERST J, NAKAMURA Y. A seismic risk for the lunar base[C]//Proceedings of the 2nd Conference on Lunar Bases and Space Activities of the 21st Century. Houston: NASA, 1992 [8] SEOL M L, HAN J W, MOON D I, et al. Triboelectric nanogenerator for Mars environment[J]. Nano Energy, 2017, 39: 238-244 doi: 10.1016/j.nanoen.2017.07.004 [9] NEALY J E, WILSON J W, TOWNSEND L W. Solar-flare Shielding with Regolith at A Lunar-base site[R]. Hampton: NASA, 1988 [10] KANAMORI H, MATSUMOTO S, ISHIKAWAD N. Long-term properties of mortar exposed to a vacuum[J]. ACI Special Publication, 1991, 125: 57-70 [11] SCHEERBAUM G. In-Situ manufacture of martian construction materials[M]//Space and Robotics 2000. Reston: American Society of Civil Engineers, 2000: 934-940 [12] ZUBRIN R. The Mars direct plan[J]. Scientific American, 2000, 282(3): 52-55 doi: 10.1038/scientificamerican0300-52 [13] DUFFIE J A, BECKMAN W A. Solar Engineering of Thermal Processes[M]. Hoboken: John Wiley & Sons, Inc. , 2013 [14] KHOSHNEVIS B, CARLSON A, THANGAVELU M. ISRU-based Robotic Construction Technologies for Lunar and Martian Infrastructures[R]. Los Angles: NASA, 2017 [15] SCOTT A, OZE C, HUGHES M W, et al. Performance of a magnesia silica cement for Martian construction[M]//MALLA R B, GOLDBERG R K, ROBERTS A D. Earth and Space 2018: Engineering for Extreme Environments. Reston: American Society of Civil Engineers, 2018: 629-636 [16] CANNON K M, MUSTARD J F. Preserved glass-rich impactites on Mars[J]. Geology, 2015, 43(7): 635-638 doi: 10.1130/G36953.1 [17] ORTIZ A R, RYGALOV V Y, DE LEÓN P. Radiation protection strategy development for mars surface exploration[C]//Proceedings of the 45th International Conference on Environmental Systems. Bellevue: ICES, 2015 [18] ZENT A P, HECHT M H, COBOS D R, et al. Thermal and electrical conductivity probe (TECP) for phoenix[J]. Journal of Geophysical Research: Planets, 2009, 114(E3): E00A27 [19] TAYLOR L A, MEEK T T. Microwave sintering of lunar soil: properties, theory, and practice[J]. Journal of Aero s pace Engineering, 2005, 18(3): 188-196 doi: 10.1061/(ASCE)0893-1321(2005)18:3(188) [20] MCKAY D S, ALLEN C C. Concrete—a practical construction material for Mars[M]//Engineering, Construction, and Operations in Space V. Reston: American Society of Civil Engineers, 1996: 566-570 [21] CLIFTON E W. Design and construction for a permanent presence on Mars[C]//Proceedings of the Fifth Case for Mars Conference. Boulder: the University of Colorado. 2000 [22] MELLEROWICZ B, ZACNY K, PALMOWSKI J, et al. RedWater: water mining system for Mars[J]. New Space, 2022, 10(2): 166-186 doi: 10.1089/space.2021.0057 [23] VAKKADA RAMACHANDRAN A, ZORZANO M P, MARTIN-TORRES J. Experimental investigation of the atmosphere-regolith water cycle on present-day Mars[J]. Sensors, 2021, 21(21): 7421 doi: 10.3390/s21217421 [24] PIQUEUX S, BUZ J, EDWARDS C S, et al. Widespread shallow water ice on Mars at high latitudes and midlatitudes[J]. Geophysical Research Letters, 2019, 46(24): 14290-14298 doi: 10.1029/2019GL083947 [25] BARKATT A, OKUTSU M. Obtaining elemental sulfur for Martian sulfur concrete[J]. Journal of Chemical Research, 2022. DOI: 10.1177/17475198221080729 [26] WAN L. Experimental and Computational Analysis of the Behavior of Ultra High Performance Concrete, Prestressed Concrete, and Waterless Martian Concrete at Early Age and Beyond[D]. Evanston: Northwestern University, 2015 [27] TOUTANJI H, GLENN-LOPER B, SCHRAYSHUEN B. Strength and durability performance of waterless lunar concrete[C]//Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit. Reno: AIAA, 2005 [28] WAN L, WENDNER R, CUSATIS G. A novel material for in situ construction on Mars: experiments and numerical simulations[J]. Construction and Building Materials, 2016, 120: 222-231 doi: 10.1016/j.conbuildmat.2016.05.046 [29] TOUTANJI H A, GRUGEL R N. Performance of “waterless concrete”[M]//Concrete Solutions. London: CRC Press, 2009: 229-232 [30] GRUGEL R N, TOUTANJI H. Sulfur “concrete” for lunar applications – Sublimation concerns[J]. Advances in Space Research, 2008, 41(1): 103-112 doi: 10.1016/j.asr.2007.08.018 [31] MANI P, GUPTA A K, KRISHNAMOORTHY S. Comparative study of epoxy and polyester resin-based polymer concretes[J]. International Journal of Adhesion and Adhesives, 1987, 7(3): 157-163 doi: 10.1016/0143-7496(87)90071-6 [32] OUSSAMA E, ELHEM G, VALÉRIE M, et al. Mechanical and physical properties of epoxy polymer concrete after exposure to temperatures up to 250℃[J]. Construction and Building Materials, 2012, 27(1): 415-424 doi: 10.1016/j.conbuildmat.2011.07.027 [33] BEDI R, CHANDRA R, SINGH S P. Mechanical properties of polymer concrete[J]. Journal of Composites, 2013, 2013: 948745 [34] BISBY L A, GREEN M F, KODUR V K R. Response to fire of concrete structures that incorporate FRP[J]. Progress in Structural Engineering and Materials, 2005, 7(3): 136-149 doi: 10.1002/pse.198 [35] TAVARES C M L, RIBEIRO M C S, FERREIRA A J M, et al. Creep behaviour of FRP-reinforced polymer concrete[J]. Composite Structures, 2002, 57(1/2/3/4): 47-51 [36] PROVIS J L, VAN DEVENTER J S J. Geopolymers: Structures, Processing, Properties and Industrial Applications[M]. Amsterdam: Elsevier, 2009 [37] RANGAN B V. Geopolymer concrete for environmental protection[J]. The Indian Concrete Journal, 2014, 88(4): 41-59 [38] SANKAR K, STYNOSKI P, AL-CHAAR G K, et al. Sodium silicate activated slag-fly ash binders: Part I – Processing, microstructure, and mechanical properties[J]. Journal of the American Ceramic Society, 2018, 101(6): 2228-2244 doi: 10.1111/jace.15391 [39] THOKCHOM S, MANDAL K K, GHOSH S. Effect of Si/Al ratio on performance of fly ash geopolymers at elevated temperature[J]. Arabian Journal for Science and Engineering, 2012, 37(4): 977-989 doi: 10.1007/s13369-012-0230-5 [40] MONTES C, BROUSSARD K, GONGRE M, et al. Evaluation of lunar regolith geopolymer binder as a radioactive shielding material for space exploration applications[J]. Advances in Space Research, 2015, 56(6): 1212-1221 doi: 10.1016/j.asr.2015.05.044 [41] NEVES J M, RAMANATHAN S, SURANENI P, et al. Characterization, mechanical properties, and microstructural development of lunar regolith simulant-portland cement blended mixtures[J]. Construction and Building Materials, 2020, 258: 120315 doi: 10.1016/j.conbuildmat.2020.120315 [42] WANG K T, TANG Q, CUI X M, et al. Development of near-zero water consumption cement materials via the geopolymerization of tektites and its implication for lunar construction[J]. Scientific Reports, 2016, 6: 29659 doi: 10.1038/srep29659 [43] PILEHVAR S, ARNHOF M, ERICHSEN A, et al. Investigation of severe lunar environmental conditions on the physical and mechanical properties of lunar regolith geopolymers[J]. Journal of Materials Research and Technology, 2021, 11: 1506-1516 doi: 10.1016/j.jmrt.2021.01.124 [44] BERNAL S A, MEJÍA DE GUTIÉRREZ R, PROVIS J L. Engineering and durability properties of concretes based on alkali-activated granulated blast furnace slag/metakaolin blends[J]. Construction and Building Materials, 2012, 33: 99-108 doi: 10.1016/j.conbuildmat.2012.01.017 [45] ALEXIADIS A, ALBERINI F, MEYER M E. Geopolymers from lunar and Martian soil simulants[J]. Advances in Space Research, 2017, 59(1): 490-495 doi: 10.1016/j.asr.2016.10.003 [46] BOYNTON W V, FELDMAN W C, SQUYRES S W, et al. Distribution of hydrogen in the near surface of Mars: evidence for subsurface ice deposits[J]. Science, 2002, 297(5578): 81-85 doi: 10.1126/science.1073722 [47] LIU N, QIU J S. Xerogel-based building material (XBM): potential for construction on Mars base and other resourceless sites[C]//Proceedings of SPIE 12044, Behavior and mechanics of multifunctional materials. Long Beach: SPIE, 2022: 120440B [48] LIU N, QIU J S. Effect of the freezing temperature and near-vacuum air pressure of Mars on the mechanical properties and microstructure of hydrogel-based concrete (HBC)[J]. Extreme Mechanics Letters, 2022, 56: 101864 doi: 10.1016/j.eml.2022.101864 [49] QIU J S, ARTIER J, COOK S, et al. Engineering living building materials for enhanced bacterial viability and mechanical properties[J]. Iscience, 2021, 24(2): 102083 doi: 10.1016/j.isci.2021.102083 [50] SIMONDS C H. Hot pressing of lunar soil and qualification for manned applications[C]//Proceedings of the 2nd Conference on Lunar Bases and Space Activities of the 21st Century. Houston: NASA, 1988 [51] PLETKA B J. Processing of lunar basalt materials[M]//LEWIS J S, MATTHEWS M S, GUERRIERI M L. Resources of Near-Earth Space. London: The University of Arizona Press, 1993: 325 [52] SRIVASTAVA V, LIM S, ANAND M. Microwave processing of lunar soil for supporting longer-term surface exploration on the Moon[J]. Space Policy, 2016, 37: 92-96 doi: 10.1016/j.spacepol.2016.07.005 [53] MCSWEEN H Y JR, TAYLOR G J, WYATT M B. Elemental composition of the martian crust[J]. Science, 2009, 324(5928): 736-739 doi: 10.1126/science.1165871 [54] KADING B, STRAUB J. Utilizing in-situ resources and 3D printing structures for a manned Mars mission[J]. Acta Astronautica, 2015, 107: 317-326 doi: 10.1016/j.actaastro.2014.11.036 [55] HAPPEL J A. Indigenous materials for lunar construction[J]. Applied Mechanics Reviews, 1993, 46(6): 313-325 doi: 10.1115/1.3120360 [56] BINDER A B, CULP M A, TOUPS L D. Lunar derived construction materials: cast basalt[C]//Proceedings of Engineering, Construction, and Operations in Space II. Albuquerque: ASCE, 1990 [57] ROGERS W P, STURE S. Indigenous lunar construction materials[C]//Proceedings of Center for Space Construction Third Annual Symposium. Boulder, Colo: Space Construction Activities, 1991 [58] ALLEN C C, HINES J A, MCKAY D S, et al. Sintering of lunar glass and basalt[C]//Proceedings of the 3rd International Conference. Denver: American Society of Civil Engineers, 1992: 1209-1218 [59] AULESA V. Architecture of lunar habitats[C]//Proceedings of the Fourth International Conference on Exploration and Utilisation of the Moon. Noordwijk: ESTEC, 2000 [60] SOBOLEV A V, DMITRIEV L V, BARSUKOV V L, et al. The formation conditions of the high-magnesium olivines from the monomineralic fraction of Luna 24 regolith[C]//Proceedings of the 11th Lunar and Planetary Science Conference. New York: Pergamon Press, 1980 [61] SCHLEPPI J, GIBBONS J, GROETSCH A, et al. Manufacture of glass and mirrors from lunar regolith simulant[J]. Journal of Materials Science, 2019, 54(5): 3726-3747 doi: 10.1007/s10853-018-3101-y [62] BLACIC J D. Mechanical properties of lunar materials under anhydrous, hard vacuum conditions: applications of lunar glass structural components[C]//Proceedings of the Lunar Bases and Space Activities of the 21st Century. Houston: Lunar and Planetary Institute, 1985 [63] AGOSTO W N, WICKMAN J H, JAMES E. Lunar cements/concretes for orbital structures[C]//Proceedings of Engineering, Construction, and Operations in Space. New York: ASCE, 1988: 157-168 [64] TUCKER D S, ETHRIDGE E C, CURREIR P. Glass Fiber Processing for the Moon/Mars Program: Center Director’s Discretionary Fund Final Report[R]. Washington: NASA, 1992 [65] GROSSMAN K. Regolith-Based Construction Materials for Lunar and Martian Colonies[D]. Florida: University of Central Florida, 2018 [66] EHLMANN B L, MUSTARD J F, MURCHIE S L, et al. Subsurface water and clay mineral formation during the early history of Mars[J]. Nature, 2011, 479(7371): 53-60 doi: 10.1038/nature10582 [67] KARL D, KAMUTZKI F, ZOCCA A, et al. Towards the colonization of Mars by in-situ resource utilization: slip cast ceramics from Martian soil simulant[J]. PLoS One, 2018, 13(10): e0204025 doi: 10.1371/journal.pone.0204025 [68] KARL D, DUMINY T, LIMA P, et al. Clay in situ resource utilization with Mars global simulant slurries for additive manufacturing and traditional shaping of unfired green bodies[J]. Acta Astronautica, 2020, 174: 241-253 doi: 10.1016/j.actaastro.2020.04.064 [69] SONG L, XU J, FAN S Q, et al. Vacuum sintered lunar regolith simulant: pore-forming and thermal conductivity[J]. Ceramics International, 2019, 45(3): 3627-3633 doi: 10.1016/j.ceramint.2018.11.023 [70] KARACASULU L, KARL D, GURLO A, et al. Cold sintering as a promising ISRU technique: a case study of Mars regolith simulant[J]. Icarus, 2023, 389: 115270 doi: 10.1016/j.icarus.2022.115270 [71] KARL D, CANNON K M, GURLO A. Review of space resources processing for Mars missions: Martian simulants, regolith bonding concepts and additive manufacturing[J]. Open Ceramics, 2022, 9: 100216 doi: 10.1016/j.oceram.2021.100216 [72] TROEMNER M, RAMYAR E, MARRERO R, et al. Marscrete: a Martian concrete for additive construction applications utilizing in situ resources[M]//Earth and Space 2021: Space Exploration, Utilization, Engineering, and Construction in Extreme Environments. Reston: American Society of Civil Engineers, 2021: 801-807 [73] GARNOCK B, BERNOLD L. Experimental study of hollow-core beams made with waterless concrete[M]//Earth and Space 2012: Engineering, Science, Construction, and Operations in Challenging Environments. Reston: American Society of Civil Engineers, 2012: 119-127 [74] MILLS J N, KATZAROVA M, WAGNER N J. Comparison of lunar and Martian regolith simulant-based geopolymer cements formed by alkali-activation for in-situ resource utilization[J]. Advances in Space Research, 2022, 69(1): 761-777 doi: 10.1016/j.asr.2021.10.045 [75] SCOTT A, OZE C, HUGHES M W. Magnesium-based cements for Martian construction[J]. Journal of Aerospace Engineering, 2020, 33(4): 04020019 doi: 10.1061/(ASCE)AS.1943-5525.0001132 -

-

程杉杉 女, 2001年10月出生于湖北省咸宁市, 现为华中科技大学土木与水利工程学院硕士生, 主要研究方向为月面原位建造材料体系. E-mail:

程杉杉 女, 2001年10月出生于湖北省咸宁市, 现为华中科技大学土木与水利工程学院硕士生, 主要研究方向为月面原位建造材料体系. E-mail:

下载:

下载: