Design and Sloshing Suppression Simulation of 2.67 L Vane-type Surface Tension Tank

-

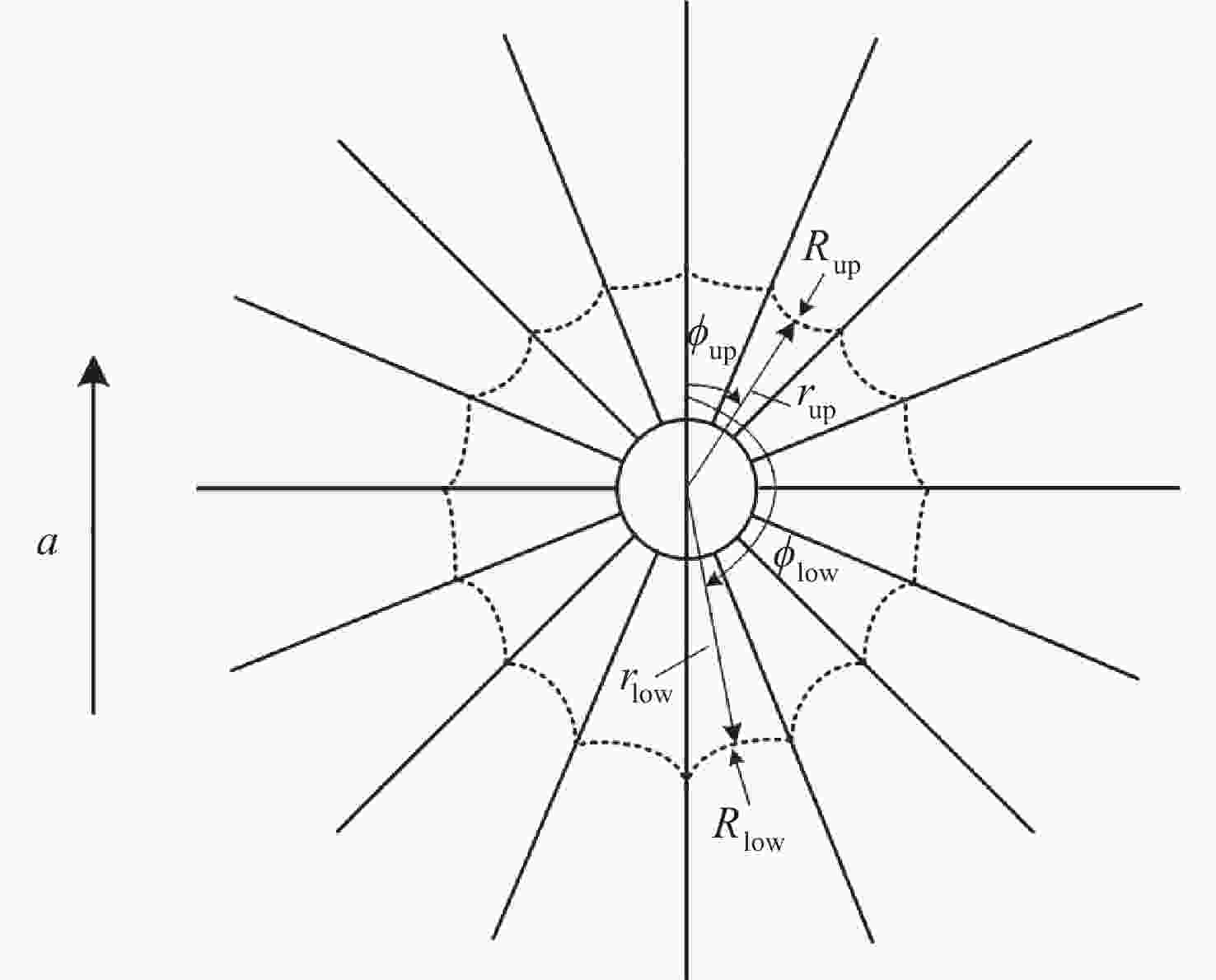

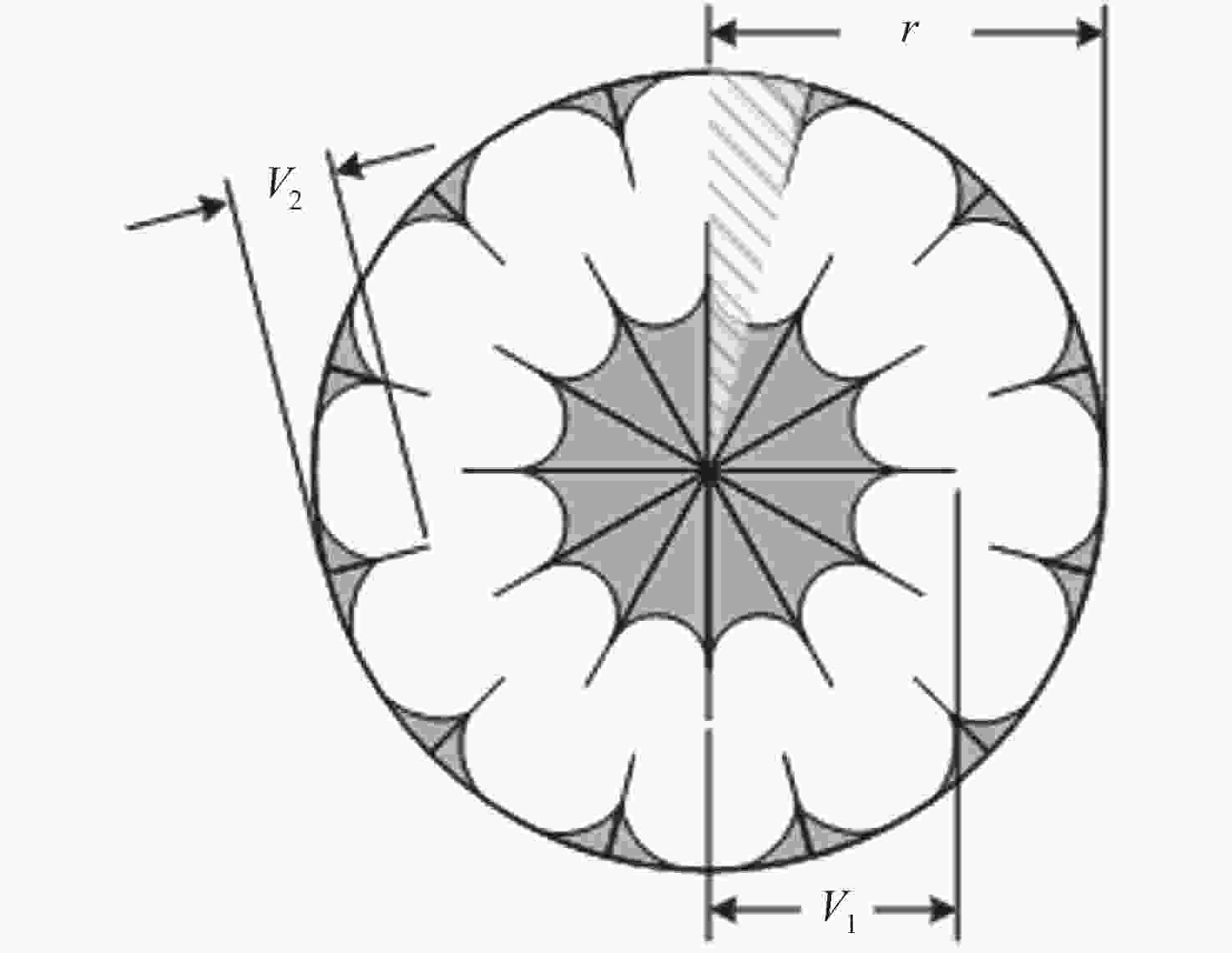

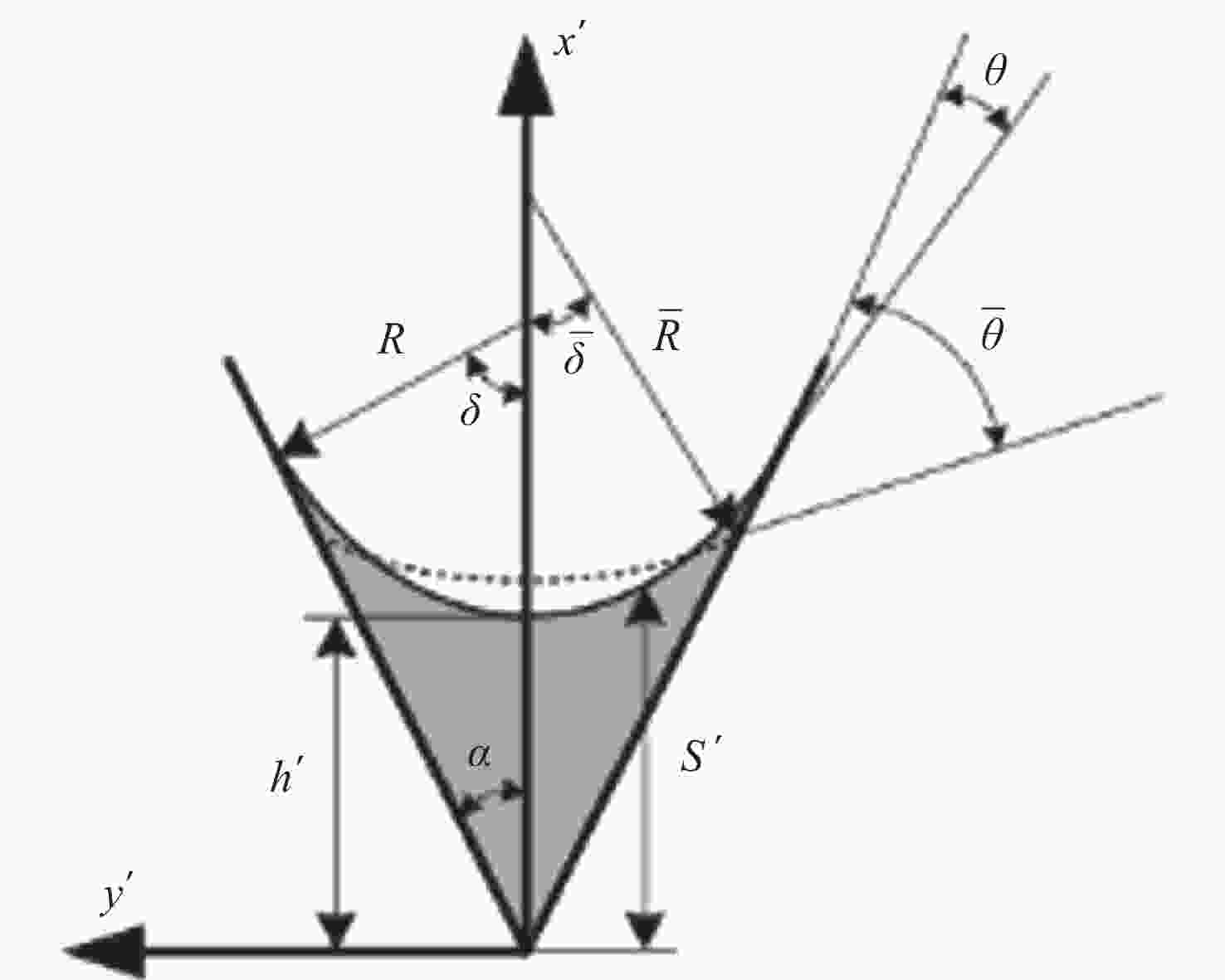

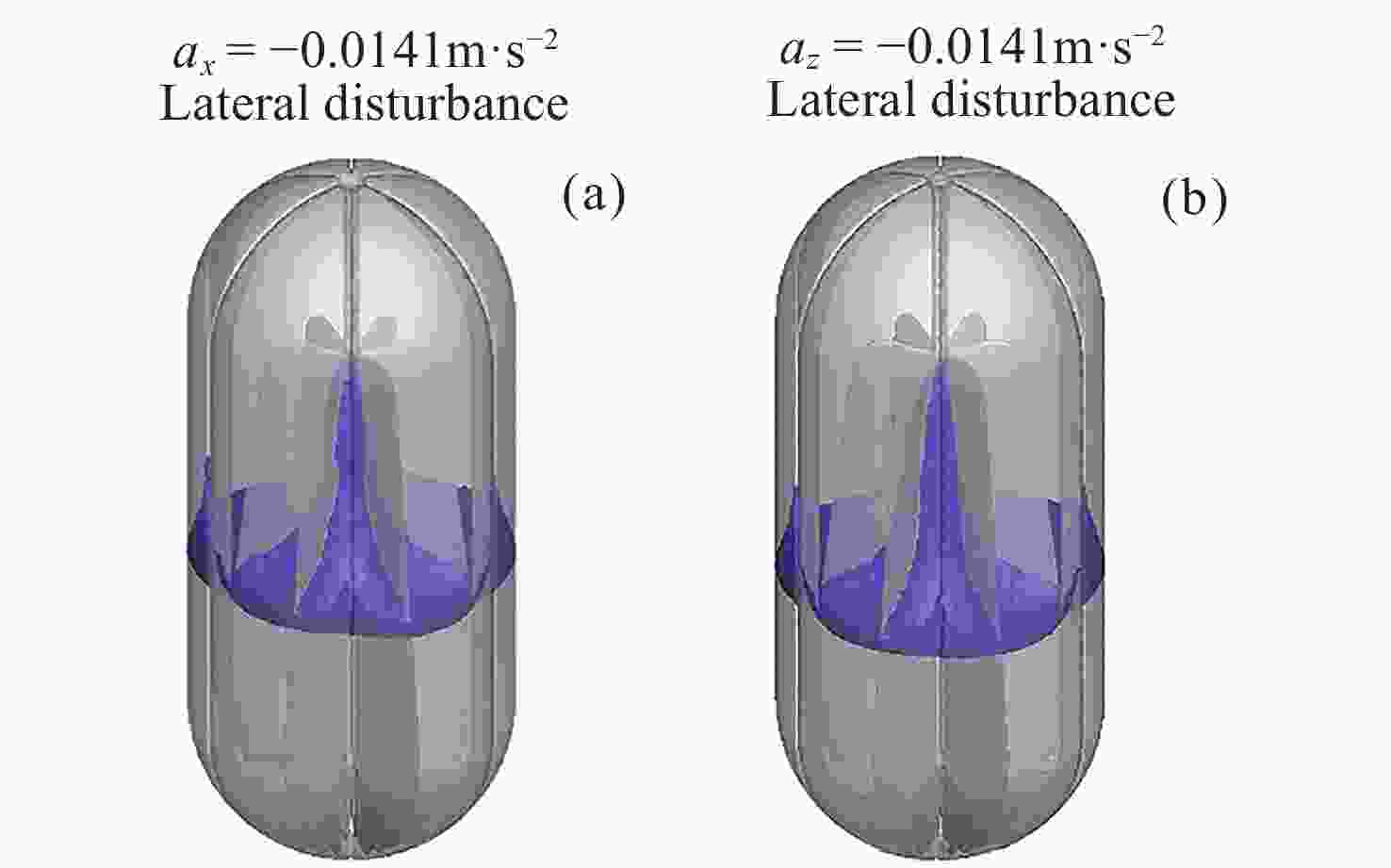

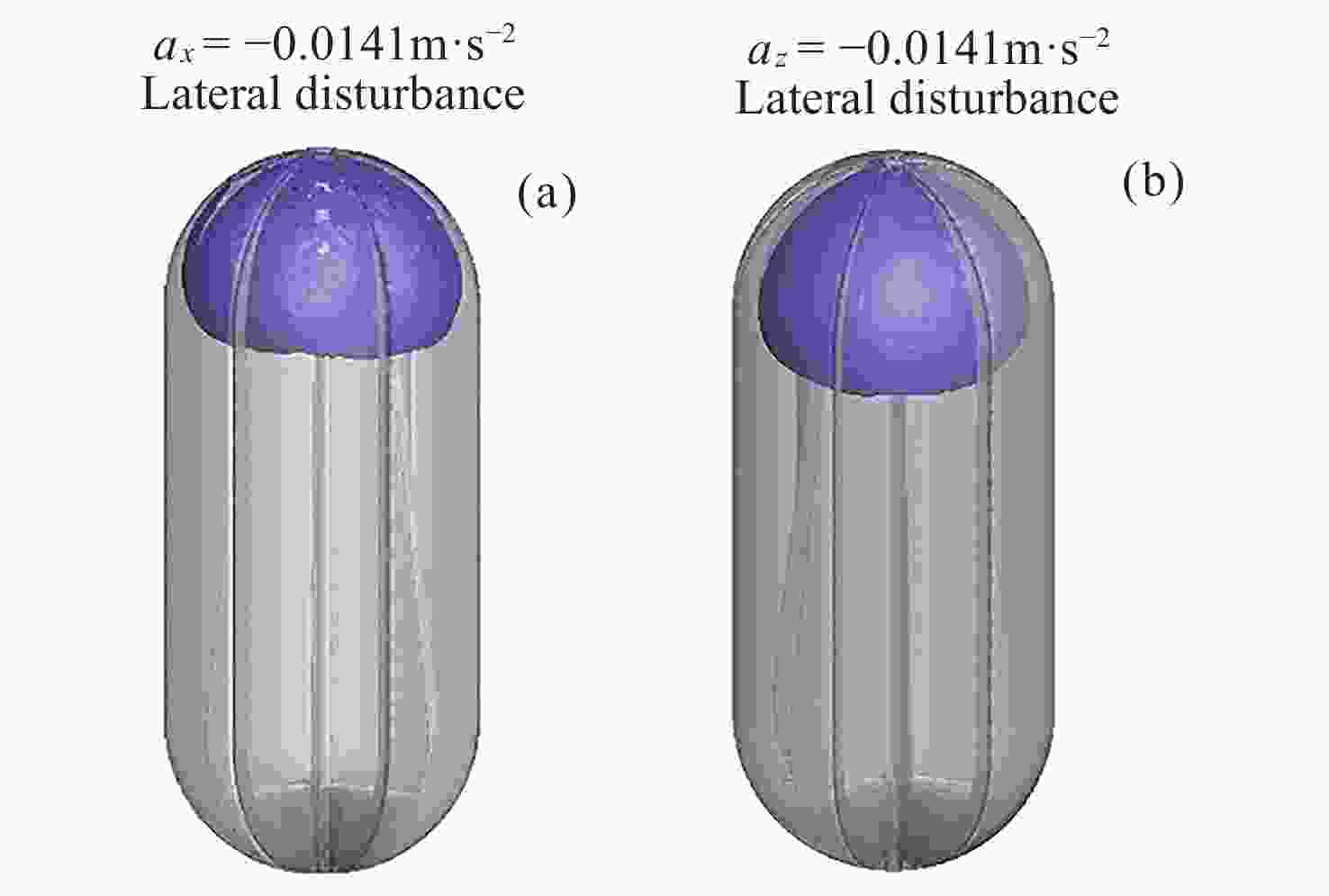

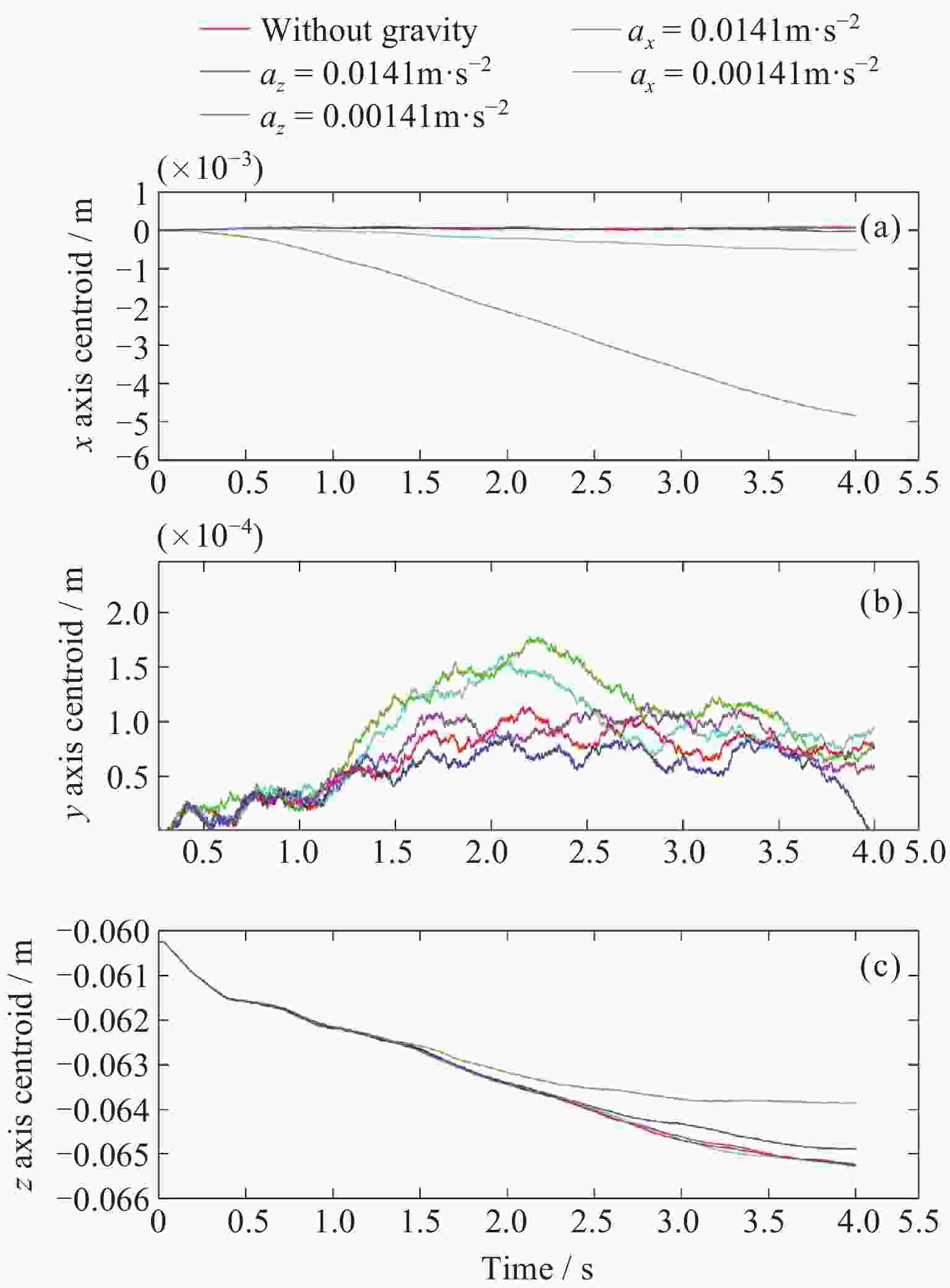

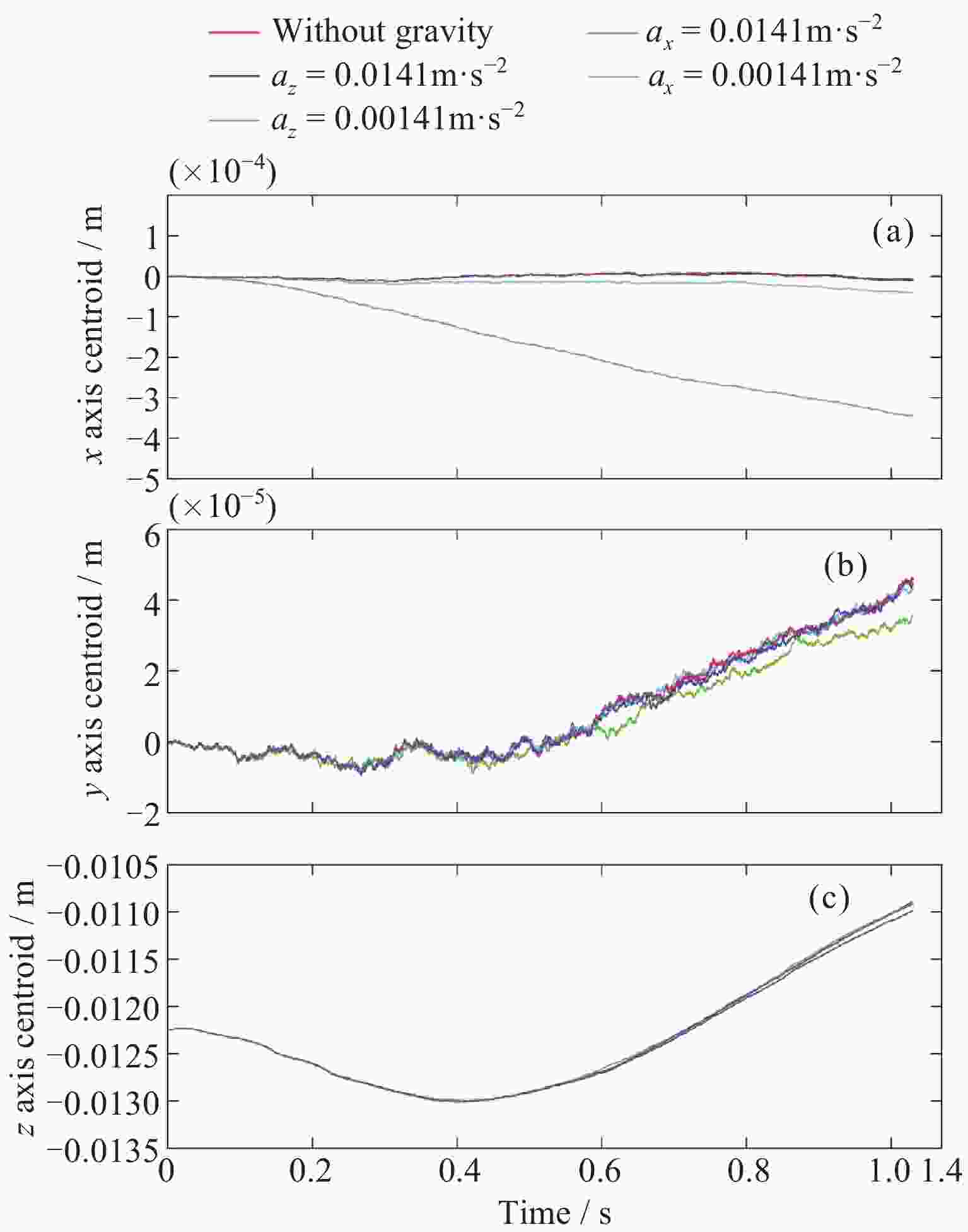

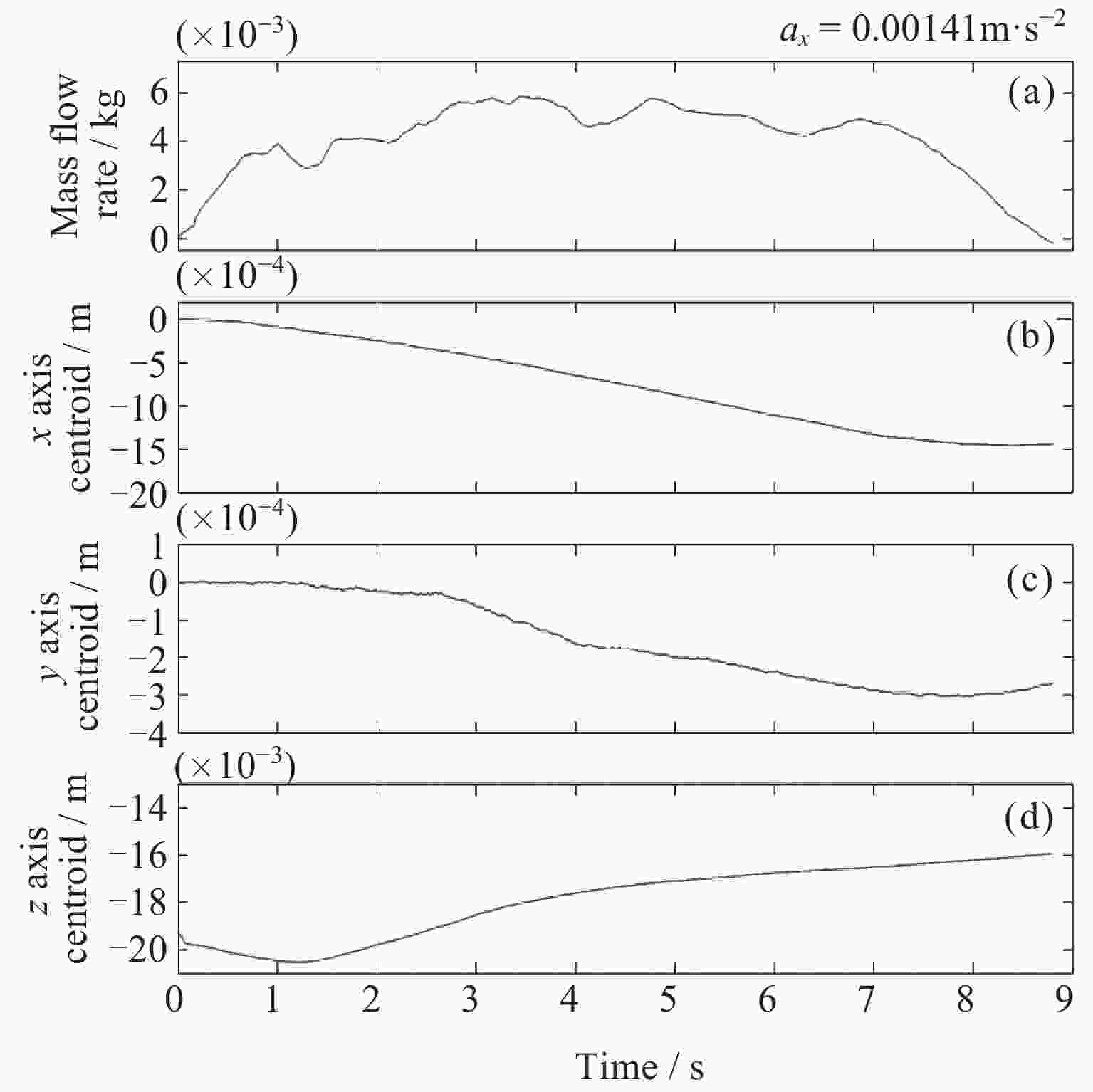

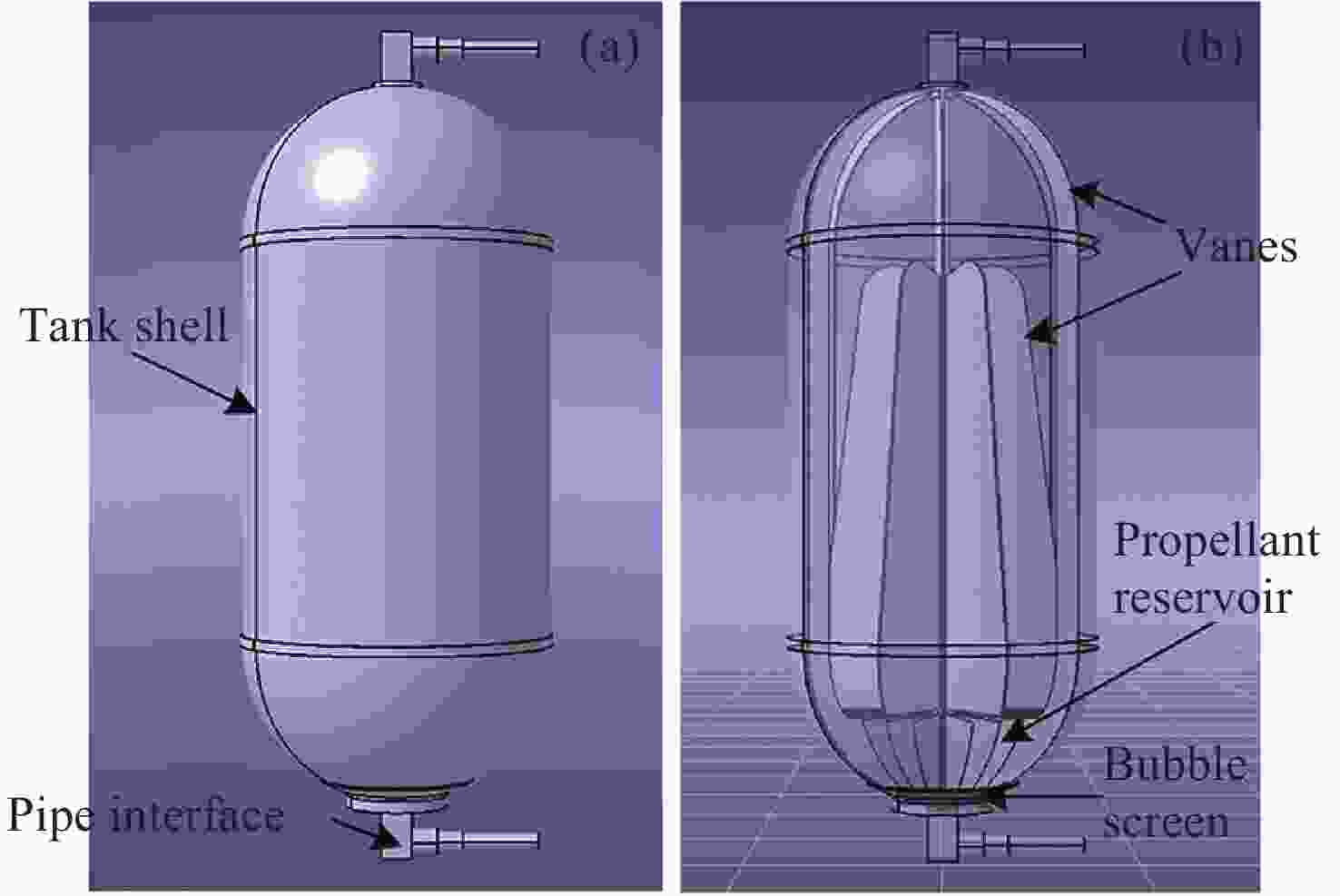

摘要: 板式表面张力贮箱因结构简单、性能良好被广泛应用于各类卫星平台. 本文针对微小卫星平台, 设计了一个2.67 L板式表面张力贮箱及其推进剂管理装置, 介绍了贮箱壳体、蓄液器、导流板和气泡筛网等主要部件的设计过程. 根据平板间的蓄流原理完成了贮箱蓄液器的设计, 得到不同加速度扰动情况下的蓄液体积; 基于内角自流理论对导流板进行几何设计并确定了内外导流板数量; 对气泡筛网进行了选型, 复核了典型工况下气泡筛网泡破点的有效性; 通过CFD仿真, 分析了贮箱在不同填充率、不同加速度扰动情况下的质心变化. 仿真结果表明, 当该贮箱受到10–3g量级加速度扰动时, 贮箱内推进剂质心变化小于10–2 m, 证明本文所设计的2.67 L板式表面张力贮箱具有较强的抗扰动特性.Abstract: Owing to its structural simplicity and superior performance, the vane-type surface tension tank has been widely applied in many satellites. In this paper, a 2.67 L vane-type propellant tank and its Propellant Management Device (PMD) were designed for micro satellites. The design process of key components, including the tank shell, propellant reservoir, vanes and bubble screen, was described in detail. Firstly, the design of the propellant reservoir was completed based on the principle of liquid accumulation between parallel plates, and the liquid volume under different acceleration disturbances was obtained. The outline and the number of internal and external vanes was carried out based on the theory of capillary flow in corners. Secondly, a bubble screen was selected and the effectiveness of the bubble screen in typical situation was checked. Finally, by CFD simulation, the centroid variation of the propellant in the tank under different fill levels and acceleration disturbances was analyzed. The simulation results demonstrate that when the tank is subjected to 10–3g acceleration disturbances, the centroid variation of the propellant is less than 10–2 m, proving that the 2.67 L vane-type surface tension tank exhibits strong resistance to disturbances.

-

Key words:

- Surface tension tank /

- PMD devices /

- Vane /

- Liquid reservoir /

- Simulation verification

-

表 1 钛合金材料部分力学性能

Table 1. Partial mechanical properties of titanium alloy

材料牌号 屈服强度$ \sigma_{0.2} $/MPa 抗拉强度$ \sigma_{\mathrm{b}} $/MPa TC4 ≥870 925~1150 TA1 ≥250 370~530 表 2 无水肼化物特性

Table 2. Characteristics of hydrazine

密度/

(kg·m–3)黏度/

(mPa·s)表面张力/

(N·m–1)接触角/(º) 1008 0.971 0.0698 5 表 3 蓄液器的蓄液能力

Table 3. Liquid storage capacity of propellant reservoir

扰动量级/ g 0.01 0.005 0.001 蓄液能力/ mL 74.6 87.4 102.6 表 4 仿真工况

Table 4. Conditions for simulation

序号 充液率/(%) 扰动大小/ (m·s–2) 扰动持续时间/s 1 50 无扰动 4 2 50 ax=–0.014 4 3 50 ax=–0.00141 4 4 50 az=–0.00141 4 5 50 az=–0.0141 4 6 80 ax=–0.00141 8.8 7 90 无扰动 1 8 90 ax=–0.014 1 9 90 ax=–0.00141 1 10 90 az=–0.00141 1 11 90 az=–0.0141 1 -

[1] 中国航天科技集团有限公司. 中国航天科技活动蓝皮书(2022年)[M]. 北京: 中国航天科技集团, 2022China Aerospace Science and Technology Corporation. Blue Book of China Aerospace Science and Technology Activities[M]. 2022 [2] DOWDY M W, DEBROCK S C. Selection of a surface-tension propellant management system for the Viking 75 orbiter[J]. Journal of Spacecraft and Rockets, 1973, 10(9): 549-558 doi: 10.2514/3.61925 [3] DOMINICK S, TEGART J. Low-g propellant transfer using capillary devices[C]//Proceedings of the AIAA/SAE/ASME 17th Joint Propulsion Conference. Colorado: AIAA, 1981 [4] BICKNELL B A, CZYSZ P M. Low-g venting tests to support on-orbit fluid resupply systems[C]//Proceedings of the AIAA/SAE/ASME/ASEE 26th Joint Propulsion Conference. Orlando: AIAA, 1990 [5] DOMINICK S M, DRISCOLL S L. Fluid acquisition and resupply experiment (FARE-I) flight results[C]//Proceedings of the 29th Joint Propulsion Conference and Exhibit. Monterey: AIAA, 1993 [6] DOMINICK S M, TEGART J R. Orbital test results of a vaned liquid acquisition device[C]//Proceedings of the AIAA/ASME/SAE/ASEE 30th Joint Propulsion Conference and Exhibit. Indianapolis: AIAA, 1994 [7] 唐飞, 姚灿, 丁凤林, 等. 某飞行器板式表面张力贮箱液体晃动分析[C]//中国航天第三专业信息网第四十届技术交流会暨第四届空天动力联合会议论文集——S02液体推进及相关技术. 北京: 北京控制工程研究所, 2019: 6. DOI: 10.26914/c.cnkihy.2019.036062 [8] 庄保堂, 李永, 潘海林, 等. 微重力环境下导流叶片流体传输速度的试验研究[J]. 空间控制技术与应用, 2012, 38(6): 1-5 doi: 10.3969/j.issn.1674-1579.2012.06.001ZHUANG Baotang, LI Yong, PAN Hailin, et al. Experiment investigation on transportation velocity of the fluid on propellant acquisition vanes under microgravity environment[J]. Aerospace Control and Application, 2012, 38(6): 1-5 doi: 10.3969/j.issn.1674-1579.2012.06.001 [9] 陈舒扬, 张璞, 胡良, 等. 板式贮箱排空过程的在轨实验和仿真研究[J]. 力学学报, 2024, 56(11): 3351-3358 doi: 10.6052/0459-1879-24-251CHEN Shuyang, ZHANG Pu, HU Liang, et al. On-orbit experimental and numerical study on the emptying process of tank models[J]. Chinese Journal of Theoretical and Applied Mechanics, 2024, 56(11): 3351-3358 doi: 10.6052/0459-1879-24-251 [10] CONCUS P, FINN R. On the behavior of a capillary surface in a wedge[J]. Proceedings of the National Academy of Sciences the United States of America, 1969, 63(2): 292-299 doi: 10.1073/pnas.63.2.292 [11] WEISLOGEL M M, LICHTER S. Capillary flow in an interior corner[J]. Journal of Fluid Mechanics, 1998, 373: 349-378 doi: 10.1017/S0022112098002535 [12] WEISLOGEL M M, JENSON R, CHEN Y K, et al. The capillary flow experiments aboard the international space station: status[J]. Acta Astronautica, 2009, 65(5/6): 861-869 [13] DONG M, CHATZIS I. The imbibition and flow of a wetting liquid along the corners of a square capillary tube[J]. Journal of Colloid and Interface Science, 1995, 172(2): 278-288 doi: 10.1006/jcis.1995.1253 [14] WEI Y X, CHEN X Q, HUANG Y Y. Interior corner flow theory and its application to the satellite propellant management device design[J]. Science China Technological Sciences, 2011, 54(7): 1849-1854 doi: 10.1007/s11431-011-4374-4 [15] LI J H, CHEN X Q, HUANG Y Y. The review of the interior corner flow research in microgravity[J]. Procedia Engineering, 2012, 31: 331-336 doi: 10.1016/j.proeng.2012.01.1032 [16] LI J H, CHEN X Q, HUANG Y Y. Capillary flow in the vane-type surface tension tank: drop tower test results[J]. Applied Mechanics and Materials, 2012, 224: 325-328 doi: 10.4028/www.scientific.net/AMM.224.325 [17] 李永强, 刘玲, 张晨辉, 等. 微重力环境下无限长柱体内角毛细流动解析近似解研究[J]. 物理学报, 2013, 62(2): 024701 doi: 10.7498/aps.62.024701LI Yongqiang, LIU Ling, ZHANG Chenhui, et al. Analytical approximations for capillary flow in interior corners of infinite long cylinder under microgravity[J]. Acta Physica Sinica, 2013, 62(2): 024701 doi: 10.7498/aps.62.024701 [18] 陈上通, 吴笛, 王佳, 等. 微重力下成一定夹角平板间的表面张力驱动流动的研究[J]. 力学学报, 2022, 54(2): 326-335 doi: 10.6052/0459-1879-21-261CHEN Shangtong, WU Di, WANG Jia, et al. Capillary rise of liquid between plates with a certain angle under microgravity[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(2): 326-335 doi: 10.6052/0459-1879-21-261 [19] CHEN S T, DUAN L, KANG Q. Study on propellant management device in plate surface tension tanks[J]. Acta Mechanica Sinica, 2021, 37(10): 1498-1508 doi: 10.1007/s10409-021-01121-y [20] LI G Y, HUANG Y Y, HAN W, et al. Space liquid transport experiments in Tianyuan-1[J]. Microgravity Science and Technology, 2022, 34(5): 100 doi: 10.1007/s12217-022-10004-1 [21] 国家市场监督管理总局, 国家标准化管理委员会. GB/T 3621-2022 钛及钛合金板材[S]. 北京: 中国标准出版社, 2022State Administration for Market Regulation, National Standardization Administration. GB/T 3621-2002 Titanium and Titanium Alloy Plate and Sheet[S]. Beijing: Standards Press of China, 2022 [22] 李亚裕. 液体推进剂[M]. 北京: 中国宇航出版社, 2011LI Yaye. Liquid Propellant[M]. Beijing: China Spaceflight Publishing House. 2011 [23] HUZEL D K. 液体火箭发动机现代工程设计[M]. 朱宁昌, 译. 北京: 中国宇航出版社, 2003: 362-370HUZEL D K. Modern Engineering For Design of Liquid–Propellant Rocket Engines[M]. ZHU Ningchang, trans. Beijing: China Astronautic Publishing House, 2003: 362-370 [24] 李永, 赵春章, 潘海林, 等. 蓄液器在板式贮箱中的应用及性能分析[J]. 宇航学报, 2008, 29(1): 24-28 doi: 10.3873/j.issn.1000-1328.2008.01.004LI Yong, ZHAO Chunzhang, PAN Hailin, et al. The applications in the vane type tank and performance analysis for the sponge[J]. Journal of Astronautics, 2008, 29(1): 24-28 doi: 10.3873/j.issn.1000-1328.2008.01.004 [25] JAEKLE JR D E. Propellant management device conceptual design and analysis: sponges[C]//Proceedings of the AIAA/SAE/ASME/ASEE 29th Joint Propulsion Conference and Exhibit. Monterey: AIAA, 1993 [26] 吴宗谕. 微重力条件下弯曲流道自由界面流动机理及其应用[D]. 长沙: 国防科技大学, 2019WU Zongyu. Investigation and Application of Free Surface Flow in Curved Channels Under Microgravity[D]. Changsha: National University of Defense Technology, 2019 [27] DE LAZZER A, LANGBEIN D, DREYER M, et al. Mean curvature of liquid surfaces in cylindrical containers of arbitrary cross-section[J]. Microgravity Science and Technology, 1996, 9(3): 208-219 [28] LI J H, CHEN X Q, HUANG Y Y, et al. Study on asymmetric interior corner flow in microgravity condition[J]. Science China Technological Sciences, 2012, 55(8): 2332-2337 doi: 10.1007/s11431-012-4841-6 [29] HARTWIG J W, DARR S R, MCQUILLEN J B, et al. A steady state pressure drop model for screen channel liquid acquisition devices[J]. Cryogenics, 2014, 64: 260-271 doi: 10.1016/j.cryogenics.2014.03.005 [30] 苗楠, 王菁, 刘战合, 等. 微重力落塔实验中的流体行为仿真与分析[J]. 应用力学学报, 2020, 37(4): 1763-1769 doi: 10.11776/cjam.37.04.A045MIAO Nan, WANG Jing, LIU Zhanhe, et al. Simulation and analysis of liquid behavior in micro-gravitational drop tower experiments[J]. Chinese Journal of Applied Mechanics, 2020, 37(4): 1763-1769 doi: 10.11776/cjam.37.04.A045 [31] LIU J T, LI Y, LI W, et al. Experimental study on liquid sloshing of a vane-type surface tension tank for satellite[J]. Microgravity Science and Technology, 2022, 34(5): 83 doi: 10.1007/s12217-022-10003-2 [32] LIU J T, LI Y, LI W, et al. Experimental investigation of liquid transport in a vane type tank of satellite with microgravity[J]. Aerospace Science and Technology, 2020, 105: 106007 doi: 10.1016/j.ast.2020.106007 [33] SMIRNOVA M N, NIKITIN V F, SKRYLEVA E I, et al. Capillary driven fluid flows in microgravity[J]. Acta Astronautica, 2023, 204: 892-899 doi: 10.1016/j.actaastro.2022.10.037 [34] BALLEREAU P, GELAS C, SALAÜN M, et al. Numerical simulation of the influence of vibrations on a free surface flow under microgravity[J]. Aerospace Science and Technology, 1997, 1(3): 191-202 doi: 10.1016/S1270-9638(97)90030-4 [35] WU Z Y, LI K, HAN W, et al. Simulation analysis of liquid flow in a vane-type surface tension tank[J]. Microgravity Science and Technology, 2022, 34(5): 80. doi: 10.1007/s12217-022-09991-y [36] 姜志杰, 吴宗谕, 刘常青, 等. 基于Surface Evolver的推进剂贮箱气液界面分析[J]. 空间科学学报, 2020, 40(6): 1066-1073 doi: 10.11728/cjss2020.06.1066JIANG Zhijie, WU Zongyu, LIU Changqing, et al. Liquid-gas interface analysis of propellant tank based on surface Evolver[J]. Chinese Journal of Space Science, 2020, 40(6): 1066-1073 doi: 10.11728/cjss2020.06.1066 [37] 黄滨, 王璐, 陈磊, 等. 侧向微重力环境下板式表面张力贮箱内推进剂晃动行为分析[J]. 空间控制技术与应用, 2021, 47(1): 63-69 doi: 10.3969/j.issn.1674-1579.2021.01.009HUANG Bin, WANG Lu, CHEN Lei, et al. Analysis of propellant sloshing behavior in vane-type surface tension tank in lateral microgravity environment[J]. Aerospace Control and Application, 2021, 47(1): 63-69 doi: 10.3969/j.issn.1674-1579.2021.01.009 [38] WANG L, ZHANG X Y, YUN Y Y, et al. Numerical simulation of the reorientation process under different conditions in a vane-type surface tension propellant tank[J]. Microgravity Science and Technology, 2022, 34(3): 37 doi: 10.1007/s12217-022-09950-7 [39] LIU Jintao, LI Yong, LI Wen, et al. Numerical simulation of the flow in a vertical vane type tank with micro downward acceleration[J]. IOP Conference Series: Materials Science and Engineering, 2020, 793(1): 012055 doi: 10.1088/1757-899X/793/1/012055 [40] 戴炜, 张钟元, 李光昱, 等. 板式表面张力贮箱推进剂重定位过程数值仿真的网格收敛性分析[J]. 中国空间科学技术, 2023, 43(4): 85-92DAI Wei, ZHANG Zhongyuan, LI Guangyu, et al. Grid convergence analysis for numerical simulation of propellant reposition process in vane-type surface tension tank[J]. Chinese Space Science and Technology, 2023, 43(4): 85-92 [41] 邱中华, 刘志杰, 朱文杰, 等. 板式表面张力贮箱导流板的理论计算与试验验证[J]. 火箭推进, 2020, 46(2): 21-28 doi: 10.3969/j.issn.1672-9374.2020.02.004QIU Zhonghua, LIU Zhijie, ZHU Wenjie, et al. Theoretical calculation and experimental verification of vanes using in vane type surface tension tank[J]. Journal of Rocket Propulsion, 2020, 46(2): 21-28 doi: 10.3969/j.issn.1672-9374.2020.02.004 -

-

李光昱 男, 1988年6月出生于江西省赣州市, 现为南昌航空大学航空宇航学院讲师, 主要研究方向为微重力流体力学、卫星在轨加注技术等. E-mail:

李光昱 男, 1988年6月出生于江西省赣州市, 现为南昌航空大学航空宇航学院讲师, 主要研究方向为微重力流体力学、卫星在轨加注技术等. E-mail:

下载:

下载: