High Performance Fibers-based Space Structure and Manufacturing Materials

-

摘要: 高性能纤维具有质量轻、强度高、化学稳定性好以及便于结构制造等显著特点, 在空间领域具有重要应用. 其在空间可展开结构中, 凭借低密度与高强度减轻了结构重量、提升了运载效率, 且兼具良好柔韧性与稳定性, 可保障结构在轨可靠运行; 在空间碎片防护结构中, 依靠优异的力学性能与抗冲击能力, 保障航天器在轨安全; 在柔性捕获网方面, 其高强度与韧性确保了捕获操作的可靠安全, 助力轨道资源维护. 随着月壤研究的深入, 其在月壤材料原位制造中展现出潜在应用价值. 结合嫦娥六号月壤最新研究成果, 探讨了月壤纤维制造技术和月球基地建造材料的发展方向. 深入研究高性能纤维在空间领域的应用, 将为空间结构设计制造提供新的思路和方法, 实现空间资源高效利用.Abstract: High performance fiber has the characteristics of light weight, high strength, good chemical stability, easy structure manufacturing, etc., and has important applications in space field. In the space deployable structure, it reduces the weight of the structure by virtue of low density and high strength, improves the carrying efficiency, and has good flexibility and stability to ensure the reliable operation of the structure in orbit. In the space debris protection structure, it relies on excellent mechanical properties and impact resistance to build a solid defense line for the spacecraft in orbit safety. In terms of flexible capture nets, high strength and toughness ensure reliable and safe capture operations and help maintain track resources. With the deepening of research on lunar soil, it shows potential application value in in-situ manufacturing of lunar soil materials. Based on the latest research results of Chang’E-6 lunar soil, the development direction of lunar soil fiber manufacturing technology and lunar base construction materials is discussed. Continuous and in-depth research on the application of high-performance fibers in the space field will provide new ideas and new methods for the design and manufacture of space structures, and open up new ways for the efficient utilization of space resources.

-

Key words:

- Fibers /

- Lunar soil /

- Space materials /

- Spatial structure /

- In-situ manufacturing

-

图 4 航天器空间碎片典型损伤. (a) STS-7任务期间微流星体在挑战者号航天飞机前窗表面留下的陨石坑, (b) 航天飞机奋进号散热器在STS-118期间表面损坏, (c) 哈勃空间望远镜太阳能阵列的穿透前视图, (d) SMM航天器体损伤

Figure 4. Typical spacecraft damages causing by space debris. (a) The crater left by a micrometeoroid on the surface of the front window of the Space Shuttle Challenger during the STS-7 mission, (b) Space Shuttle Endeavour radiator surface damage during STS-118, (c) penetrating front view of the Hubble Space Telescope solar array, (d) SMM (Solar Maximum Mission) spacecraft body damage

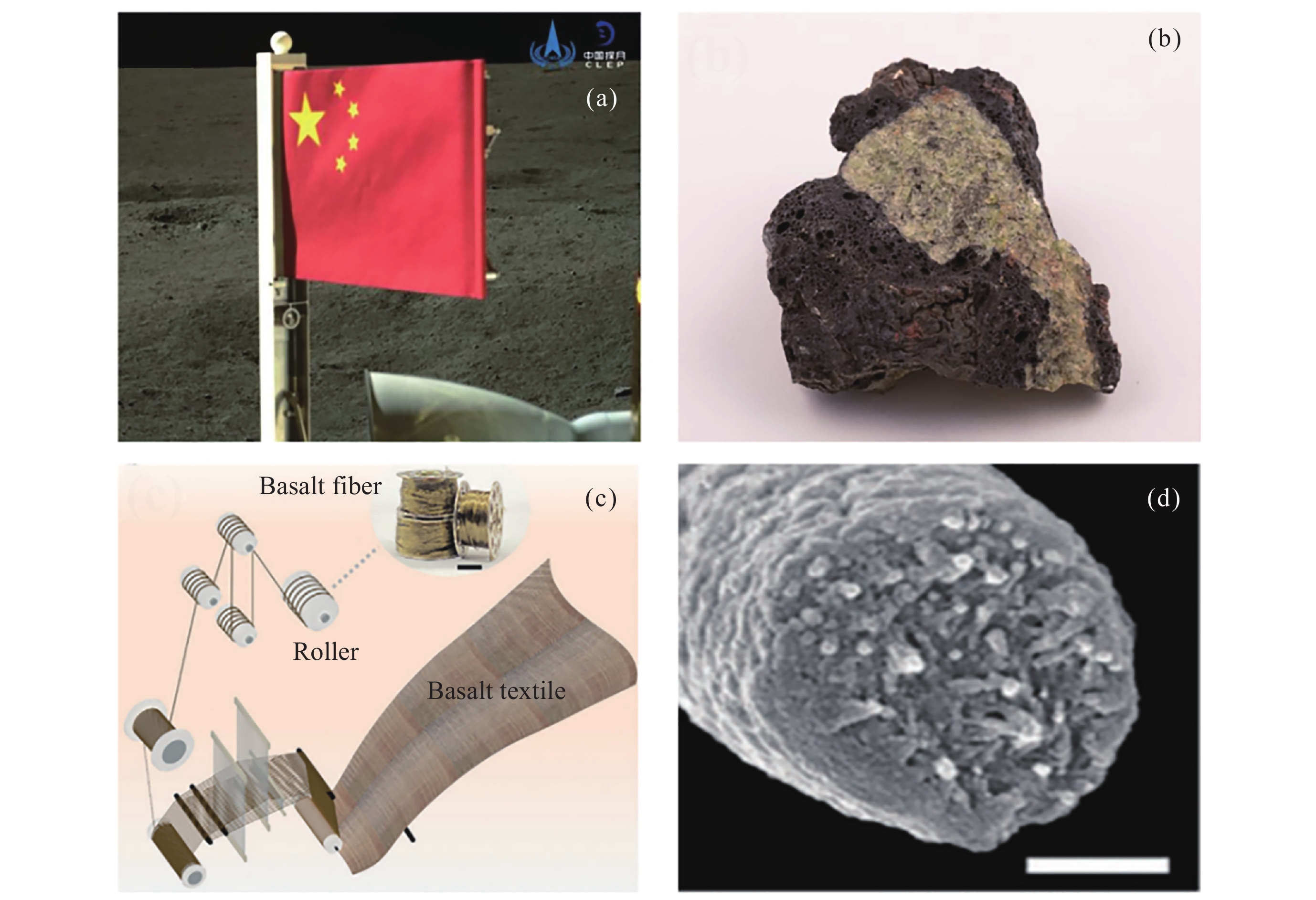

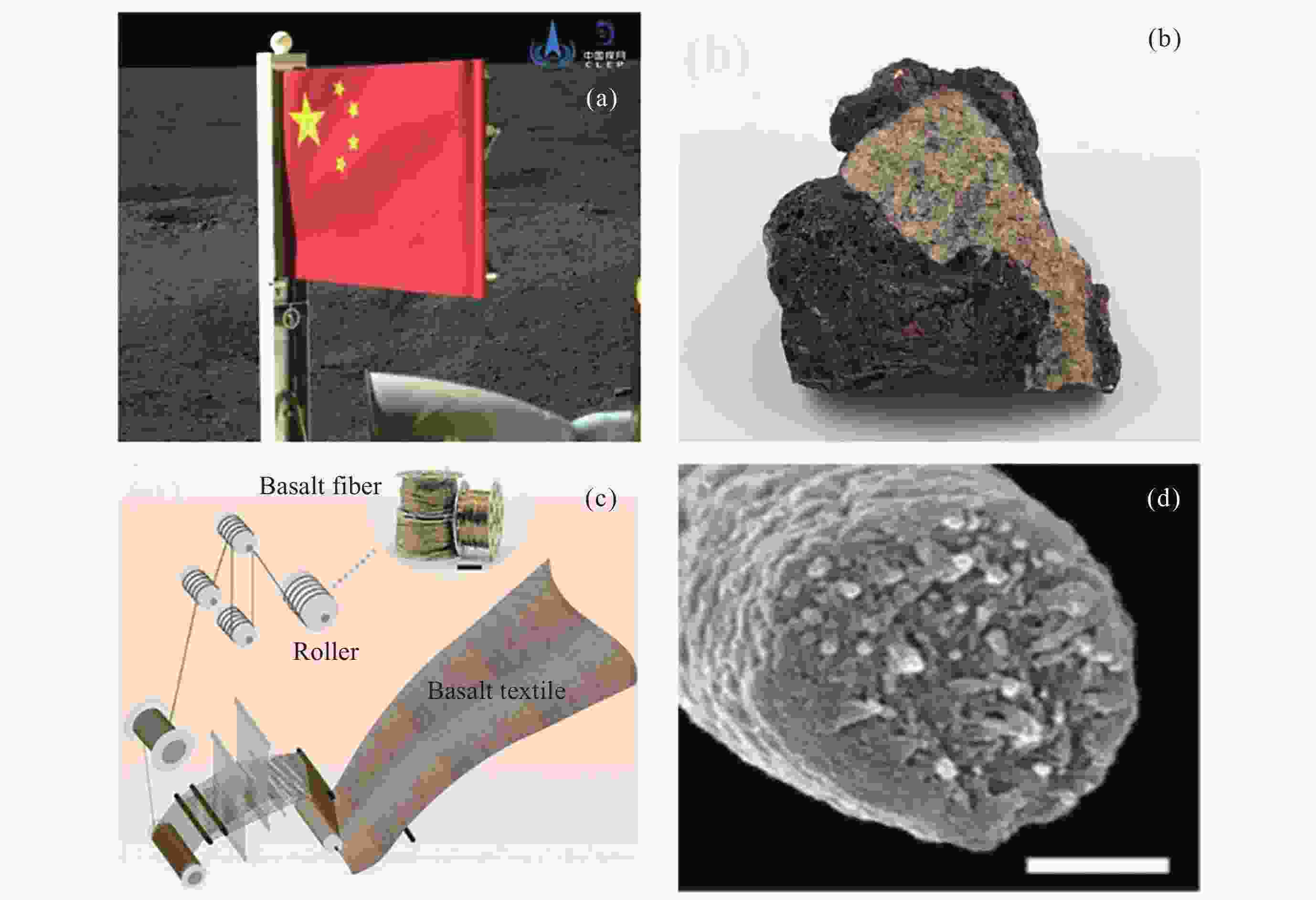

图 7 嫦娥六号带回的代表性样本. (a) 从嫦娥六号采集的样品中筛选出的部分直径超过1 mm的岩石碎片, (b)~(e) 不同结构特征的玄武岩碎片, (f)(g) 角砾岩, (h) 黏结岩的背散射电子图像, (i)(j) 典型的玄武岩, (k) 黏结岩, (l) 浅色岩石碎片, (m)(n) 玻璃质材料的显微照片

Figure 7. Typical images of Chang’E-6 returned samples. (a) Fragments larger than 1 mm, (b)~(e) basaltic fragments with different structural characteristics, (f)(g) breccia, (h) binder rock backscatter images, (i)(j) typical basalts, (k) bonding rocks, (l) light-colored cuttings, (m)(n) glassy materials

表 1 常用高性能纤维性能比较

Table 1. Performance comparison of common high performance fibers

材料类型 断裂强度/GPa 模量/GPa 断裂伸长率/(%) 线密度/(g·m–1) 使用温度/℃ 抗辐照性 PI 3.0~3.5 120~140 2 1.41 200~300 优良 PBO 58 180 3.5 1.54~1.56 300 一般 UHMw-PE 3.2 99 3.7 0.97 <80 优良 聚芳酯纤维 2.6~3.0 72~85 2~5 1.41 250 一般 碳纤维 3~7.0 230~600 1~2 1.76~1.82 600 优良 玄武岩纤维 3~4.84 91~110 2~3.2 2.65~3.05 700 优良 Kevlar29 2.76 63 4 1.44 250 弱 Kevlar49 3.5 124 2.4 1.44 250 弱 芳纶Ⅲ 4.2~5.0 130~155 3.2~4.1 1.43~1.45 270 弱 -

[1] 嫦娥六号完成采样上升器从月背起飞进入预定环月轨道[N/OL](2024-06-04). https://www.cnsa.gov.cn/n6758823/n6758838/c10543020/content.htmlChang 6 complete sampling ascenders from month back into the rings on take-off track (2024-06-04) [N/OL]. https://www.cnsa.gov.cn/n6758823/n6758838/c10543020/content.html [2] LI, GUO, FU F, et al. Triboelectric basalt textiles efficiently operating within an ultrawide temperature range[J]. Advanced Materials, 2024, 36(28): 2401359 doi: 10.1002/adma.202401359 [3] LI, HU H, YANG, et al. Nature of the lunar far-side samples returned by the Chang’E-6 mission[J]. National Science Review, 2024, 11(11): nwae328 doi: 10.1093/nsr/nwae328 [4] 马鹏程, 郭泽世, 苏秀中, 等. 月壤纤维材料研究进展与展望[J]. 深空探测学报, 2023, 10(5): 532-543MA Pengcheng, GUO Zeshi, SU Xiuzhong, et al. Progress and perspect of lunar fiber materials[J]. Journal of Deep Space Exploration, 2023, 10(5): 532-543 [5] 邢丹, 葸雄宇, 郭泽世, 等. 模拟月壤制备连续纤维的可行性研究[J]. 中国科学: 技术科学, 2020, 50(12): 1625-1633XING Dan, XI Xiongyu, GUO Zeshi, et al. Study on the feasibility of preparing a continuous fibre using lunar soil simulant[J]. Science in China: Technical Sciences, 2020, 50(12): 1625-1633 [6] MA X F, LI T J, MA J Y, et al. Recent advances in space-deployable structures in China[J]. Engineering, 2022, 17(10): 207-219 [7] WANG B, ZHU J C, ZHONG S C, et al. Space deployable mechanics: a review of structures and smart driving[J]. Materials :Times New Roman;">& Design, 2024, 237: 112557 [8] MA X F, AN N, CONG Q, et al. Design, modeling, and manufacturing of high strain composites for space deployable structures[J]. Communications Engineering, 2024, 3(1): 78 doi: 10.1038/s44172-024-00223-2 [9] 冷劲松, 兰鑫, 刘彦菊, 等. 形状记忆聚合物复合材料及其在空间可展开结构中的应用[J]. 宇航学报, 2010, 31(4): 950-956 doi: 10.3873/j.issn.1000-1328.2010.04.002LENG Jinsong, LAN Xin, LIU Yanju, et al. Shape memory polymer composites and their applications in space deployable structures[J]. Journal of Astronautics, 2010, 31(4): 950-956 doi: 10.3873/j.issn.1000-1328.2010.04.002 [10] 贾文文, 濮海玲, 刘颖, 等. 刚性基体高应变复合材料在空间可展结构中的应用及发展[J]. 宇航材料工艺, 2023, 53(2): 14-21 doi: 10.12044/j.issn.1007-2330.2023.02.003JIA Wenwen, PU Hailing, LIU Ying, et al. Application and development of stiff matrix high strain composites in deployable space structures[J]. Aerospace Materials :Times New Roman;">& Technology, 2023, 53(2): 14-21 doi: 10.12044/j.issn.1007-2330.2023.02.003 [11] SVOTINA V V. Spacecraft protection against man-made and natural space debris particles[J]. Acta Astronautica, 2024, 225: 538-555 doi: 10.1016/j.actaastro.2024.09.053 [12] CHEN Y, TANG Q Y, HE Q G, et al. Review on hypervelocity impact of advanced space debris protection shields[J]. Thin-Walled Structures, 2024, 200: 111874 doi: 10.1016/j.tws.2024.111874 [13] Christiansen E L, Kerr J H. Flexible and deployable meteoroid/debris shielding for spacecraft[J]. International Journal of Impact Engineering, 1999, 23(1): 125-136 doi: 10.1016/S0734-743X(99)00068-8 [14] PAI A, DIVAKARAN R, ANAND S, et al. Advances in the Whipple shield design and development: a brief review[J]. Journal of Dynamic Behavior of Materials, 2022, 8(1): 20-38 doi: 10.1007/s40870-021-00314-7 [15] 韩增尧, 庞宝君. 空间碎片防护研究最新进展[J]. 航天器环境工程, 2012, 29(4): 369-378 doi: 10.3969/j.issn.1673-1379.2012.04.004HAN Zengyao, PANG Baojun. Review of recent development of space debris protection research[J]. Spacecraft Environment Engineering, 2012, 29(4): 369-378 doi: 10.3969/j.issn.1673-1379.2012.04.004 [16] 苟海涛, 王应德, 闫军, 等. 一种高性能复合织物填充防护结构撞击极限研究和防护机理分析[C]//武汉: 中国空间科学学会空间材料专业委员会, 2012GOU Haitao, WANG Yingde, YAN Jun, et al. Experimental study of hypervelocity impact on an advanced composite Fibric stuffed Whipple shield[C]//Wuhan: the Space Materials Committee, Chinese Society of Space Research, 2012 [17] WU N, LIU S K, ZHANG X S, et al. Progress on space materials science in China: debris shielding fibrous materials and high specific energy lithium sulfur batteries[J]. Chinese Journal of Space Science, 2022, 42(4): 803-811 doi: 10.11728/cjss2022.04.yg24 [18] BAI Y X, YUE H J, WANG J, et al. Super-durable ultralong carbon nanotubes[J]. Science, 2020, 369(6507): 1104-1106 doi: 10.1126/science.aay5220 [19] ZHANG X S, LEI X D, JIA X Z, et al. Carbon nanotube fibers with dynamic strength up to 14 GPa[J]. Science, 2024, 384(6702): 1318-1323 doi: 10.1126/science.adj1082 [20] SHAN M H, GUO J, GILL E. Review and comparison of active space debris capturing and removal methods[J]. Progress in Aerospace Science, 2016, 80: 18-32 doi: 10.1016/j.paerosci.2015.11.001 [21] SVOTINA V V. Spacecraft protection against man-made and natural space debris particles[J]. Acta Astronautica, 2024, 225: 538-555 doi: 10.1016/j.actaastro.2024.09.053 [22] JOHNSON N L. Debris removal: an opportunity for cooperative research[C]//Proceedings of Space Situational Awareness Conference. Washington: NASA, 2007 [23] TANG C, DENG Y Q, BAI Z F, et al. Dynamics analysis of space netted pocket system capturing non-cooperative target[J]. Applied Sciences, 2023, 13(18): 10377 doi: 10.3390/app131810377 [24] BISCHOF B, KERSTEIN L, STARKE J, et al. ROGER-robotic geostationary orbit restorer[C]//54th International Astronautical Congress of the International Astronautical Federation, the International Academy of Astronautics, and the International Institute of Space Law. Bremen, Germany: IAC, 2003 [25] FORSHAW J L, AGLIETTI G S, FELLOWES S, et al. The active space debris removal mission RemoveDebris. Part 1: from concept to launch[J]. Acta Astronautica, 2020, 168: 293-309 doi: 10.1016/j.actaastro.2019.09.002 [26] AGLIETTI G S, TAYLOR B, FELLOWES S, et al. The active space debris removal mission RemoveDebris. Part 2: in orbit operations[J]. Acta Astronautica, 2020, 168: 310-322 doi: 10.1016/j.actaastro.2019.09.001 [27] 许望晶, 王立武, 唐明章, 等. 空间抓捕系统绳网的设计与研制[J]. 航天器工程, 2021, 30(2): 54-59 doi: 10.3969/j.issn.1673-8748.2021.02.008XU Wangjing, WANG Liwu, TANG Mingzhang, et al. Design and development of space net for capture system[J]. Spacecraft Engineering, 2021, 30(2): 54-59 doi: 10.3969/j.issn.1673-8748.2021.02.008 [28] BENVENUTO R, CARTA R. Active debris removal system based on tethered-nets: experimental results[C]//9th Pegasus-AIAA Aerospace Student Conference. Milano, Italy: AIAA, 2013 [29] 姜生元, 沈毅, 吴湘, 等. 月面广义资源探测及其原位利用技术构想[J]. 深空探测学报, 2015, 2(4): 291-301JIANG Shengyuan, SHEN Yi, WU Xiang, et al. Technical schemes of investigation and in-situ utilization for lunar surface generalized resources[J]. Journal of Deep Space Exploration, 2015, 2(4): 291-301 [30] 刘琛, 李勇, 周文, 等. 模拟月/火星壤的原位成型技术研究进展[J]. 材料导报, 2022, 36(22): 22050122 doi: 10.11896/cldb.22050122LIU C, LI Y, ZHOU W, et al. In-situ forming technology of lunar/martian soil simulant[J]. Materials Reports, 2022, 36(22): 22050122 doi: 10.11896/cldb.22050122 [31] ZHAO H, MENG L, LI S Y, et al. Development of lunar regolith composite and structure via laser-assisted sintering[J]. Frontiers of Mechanical Engineering, 2022, 17(1): 6-18 doi: 10.1007/s11465-021-0662-2 [32] LEACH N. 3D printing in space[J]. Architectural Design, 2014, 84: 108-113 [33] GHIDINI T, GRASSO M, GUMPINGER J, et al. Additive manufacturing in the new space economy: current achievements and future perspectives[J]. Progress in Aerospace Sciences, 2023, 142: 100959 doi: 10.1016/j.paerosci.2023.100959 [34] ZHOU C, GAO Y Y, ZHOU Y, et al. Properties and characteristics of regolith-based materials for extraterrestrial construction[J]. Engineering, 2024, 37(6): 159-181 [35] 吴灵芝, 尹海清, 张聪, 等. 增材制造月壤原位成形技术的研究现状[J]. 矿产综合利用, 2023(6): 99-107 doi: 10.3969/j.issn.1000-6532.2023.06.015WU Lingzhi, YIN Haiqing, ZHANG Cong, et al. Research status of additive manufacturing lunar in-situ forming technology[J]. Multipurpose Utilization of Mineral Resources, 2023(6): 99-107 doi: 10.3969/j.issn.1000-6532.2023.06.015 [36] LIU M, TANG W Z, DUAN W Y, et al. Digital light processing of lunar regolith structures with high mechanical properties[J]. Ceramics International, 2019, 45(5): 5829-5836 doi: 10.1016/j.ceramint.2018.12.049 [37] GOULAS A, FRIEL R J. 3D printing with moondust[J]. Rapid Prototyping Journal, 2016, 22(6): 864-870 doi: 10.1108/RPJ-02-2015-0022 [38] GOULAS A, BINNER J G P, HARRIS R A, et al. Assessing extraterrestrial regolith material simulants for in-situ resource utilisation based 3D printing[J]. Applied Materials Today, 2017, 6: 54-61 doi: 10.1016/j.apmt.2016.11.004 [39] 李雯, 徐可宁, 黄勇, 等. 基于SLM的模拟月壤原位成形技术[J]. 北京航空航天大学学报, 2019, 45(10): 1931-1937LI Wen, XU Kening, HUANG Yong, et al. In-situ forming of lunar regolith simulant via selective laser melting[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(10): 1931-1937 [40] MONALDO E, NERILLI F, VAIRO G. Basalt-based fiber-reinforced materials and structural applications in civil engineering[J]. Composite Structures, 2019, 214: 246-263 doi: 10.1016/j.compstruct.2019.02.002 [41] GUO Z S, XING D, XI X Y, et al. Production of Fibres from lunar soil: feasibility, applicability and future perspectives[J]. Advanced Fiber Materials, 2022, 4(5): 923-937 doi: 10.1007/s42765-022-00156-5 [42] HO D, SOBON L E. Extraterrestrial Fiberglass Production Using Solar Energy[R]. NASA, 1979: 225-232 [43] WANG H W, ZENG C, WANG C, et al. Fibration of powdery materials[J]. Nature Materials, 2024, 23(5): 596-603 doi: 10.1038/s41563-024-01821-3 -

-

赵洋 男, 2002年4月出生于辽宁省辽阳市, 国防科技大学空天科学学院硕士研究生, 主要研究方向为陶瓷纤维与先驱体及其应用. E-mail:

赵洋 男, 2002年4月出生于辽宁省辽阳市, 国防科技大学空天科学学院硕士研究生, 主要研究方向为陶瓷纤维与先驱体及其应用. E-mail:

下载:

下载: