Research on Heat Dissipation of Split Diamond/Copper Microchannels

-

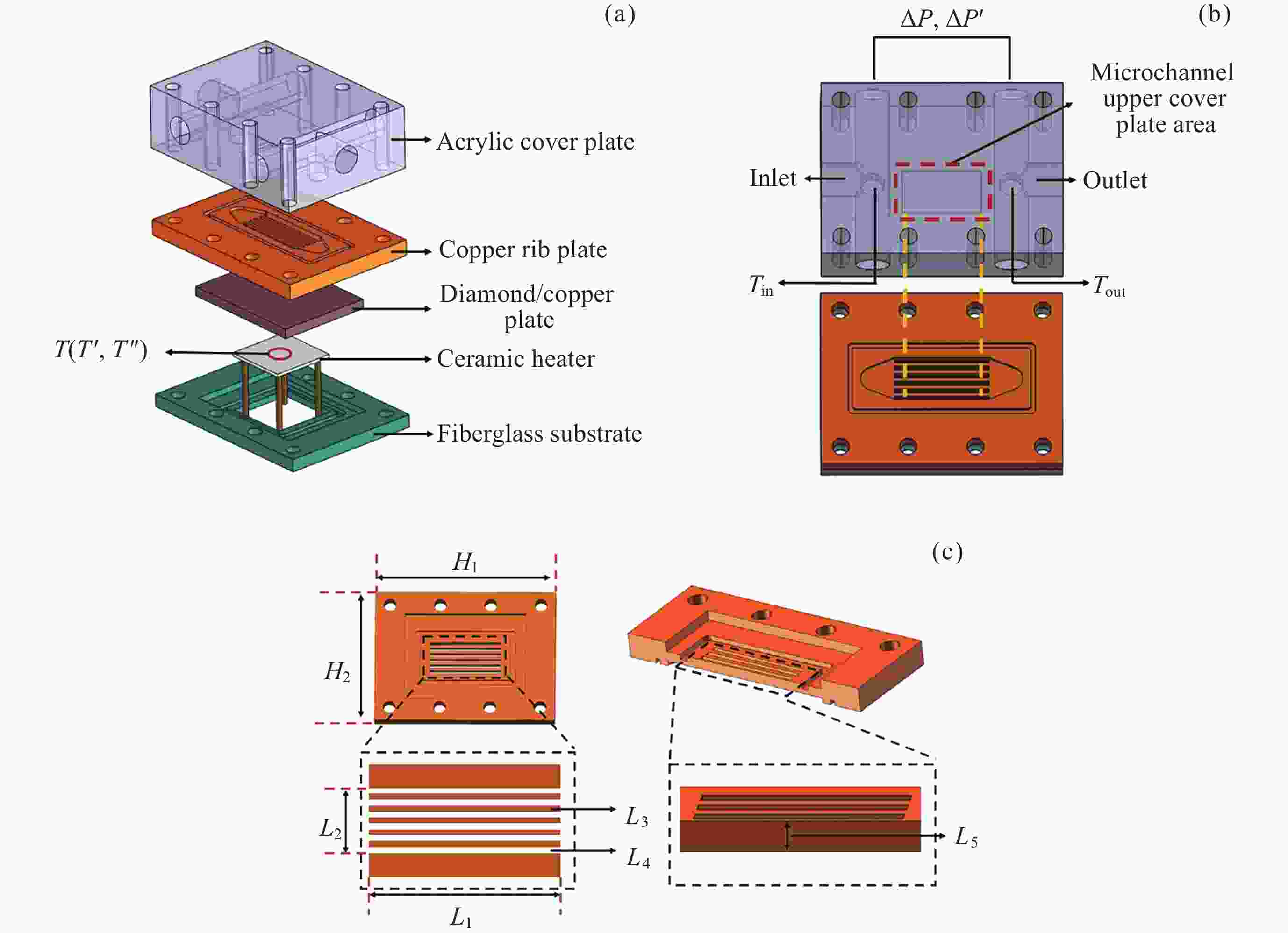

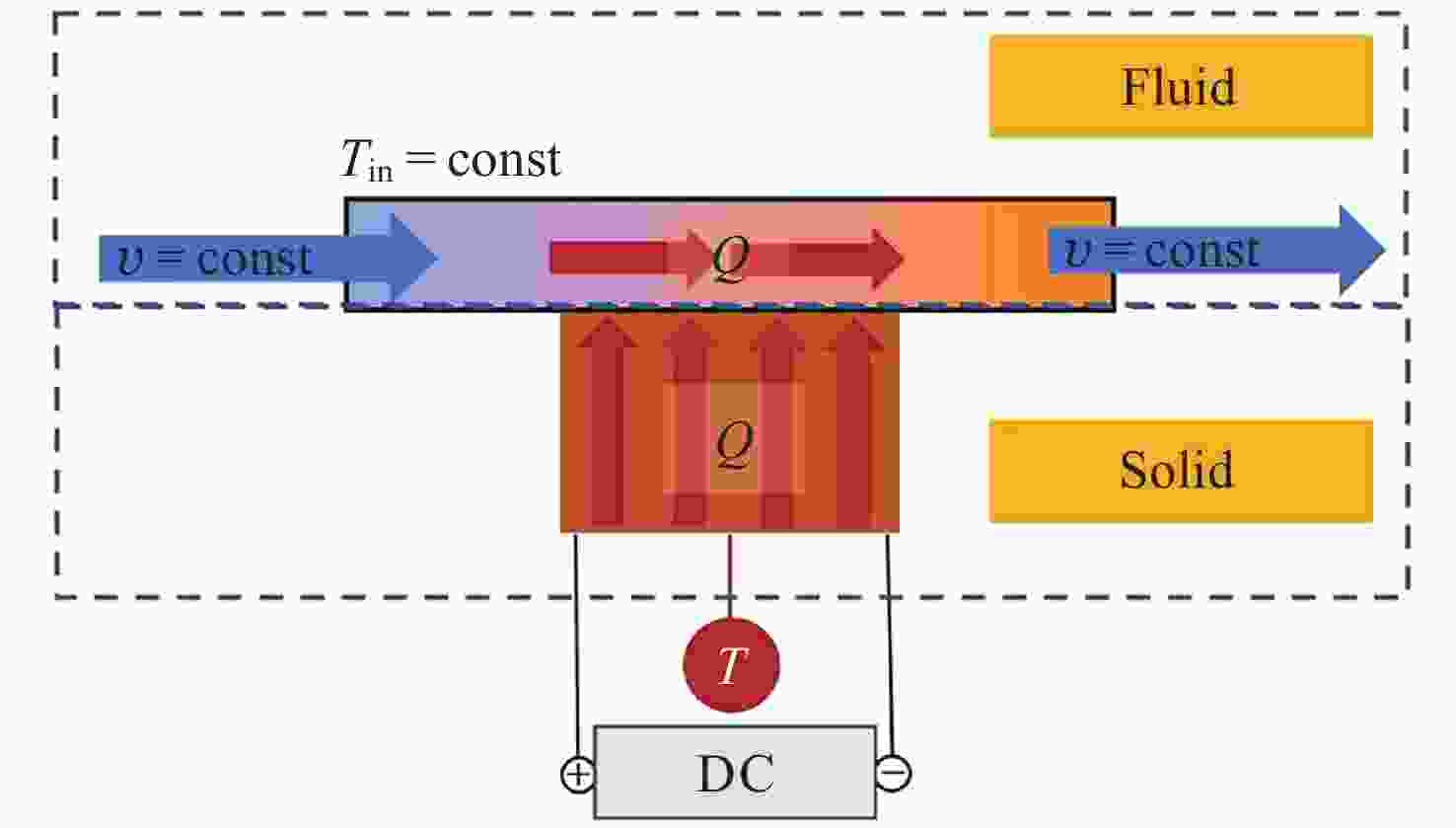

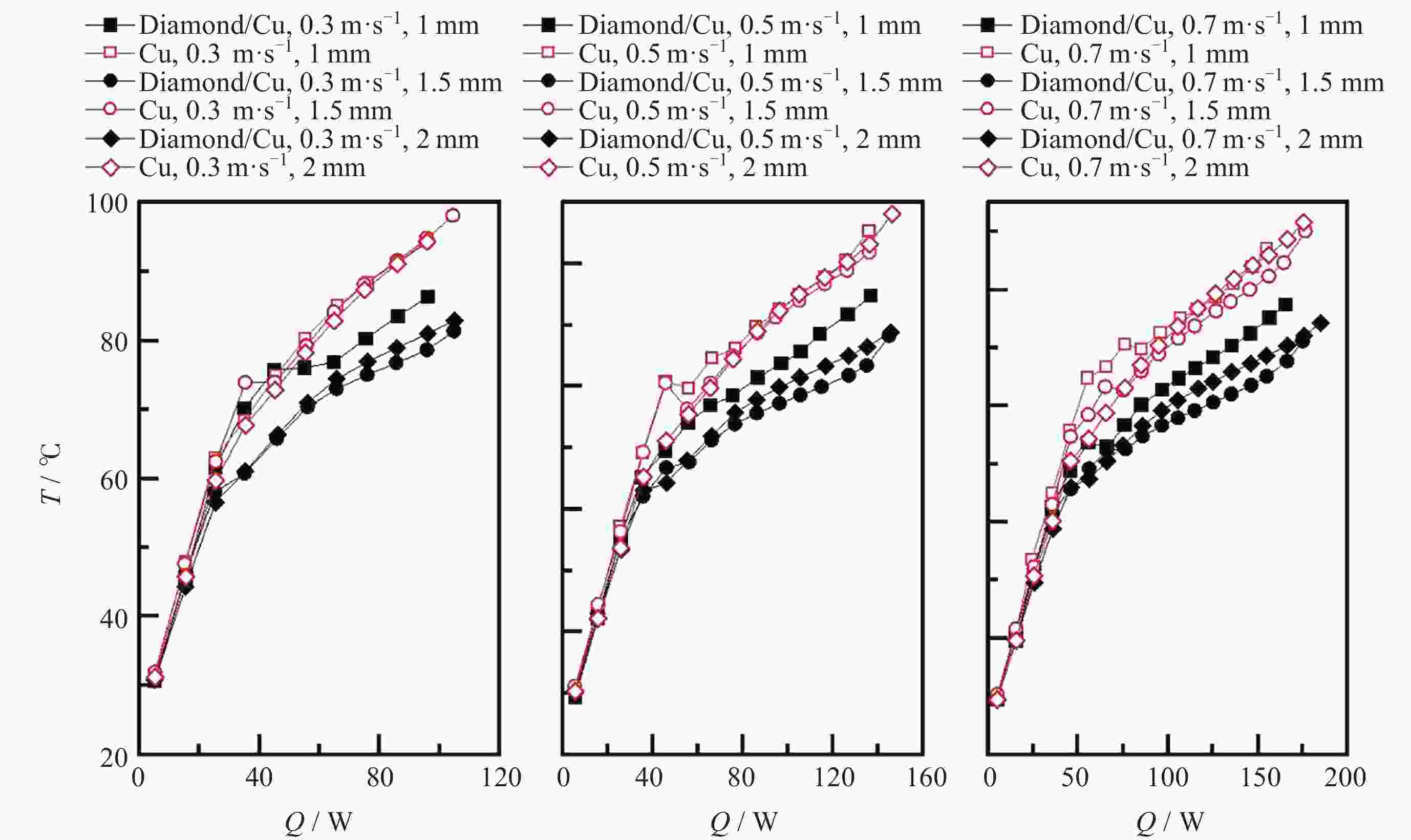

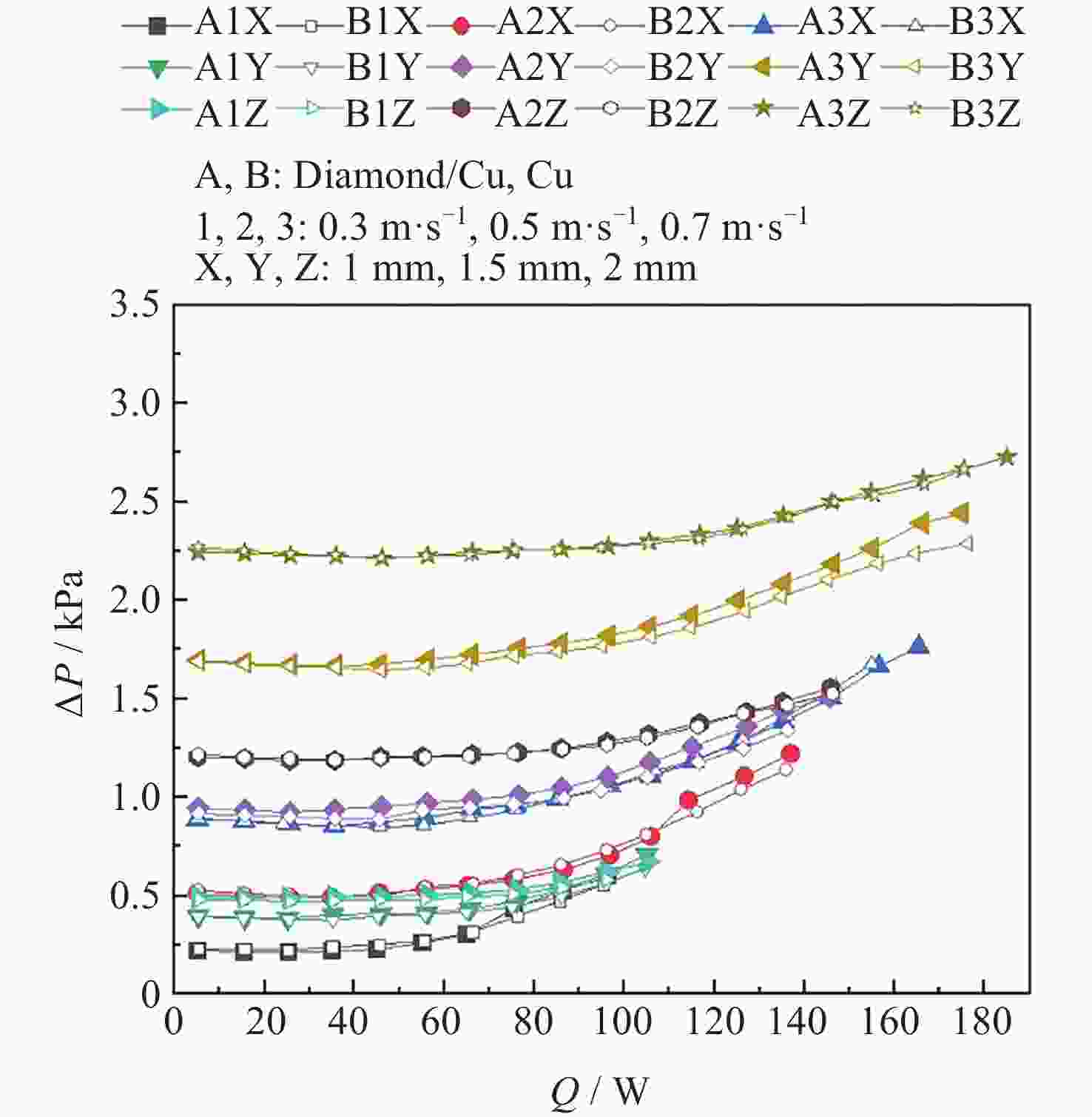

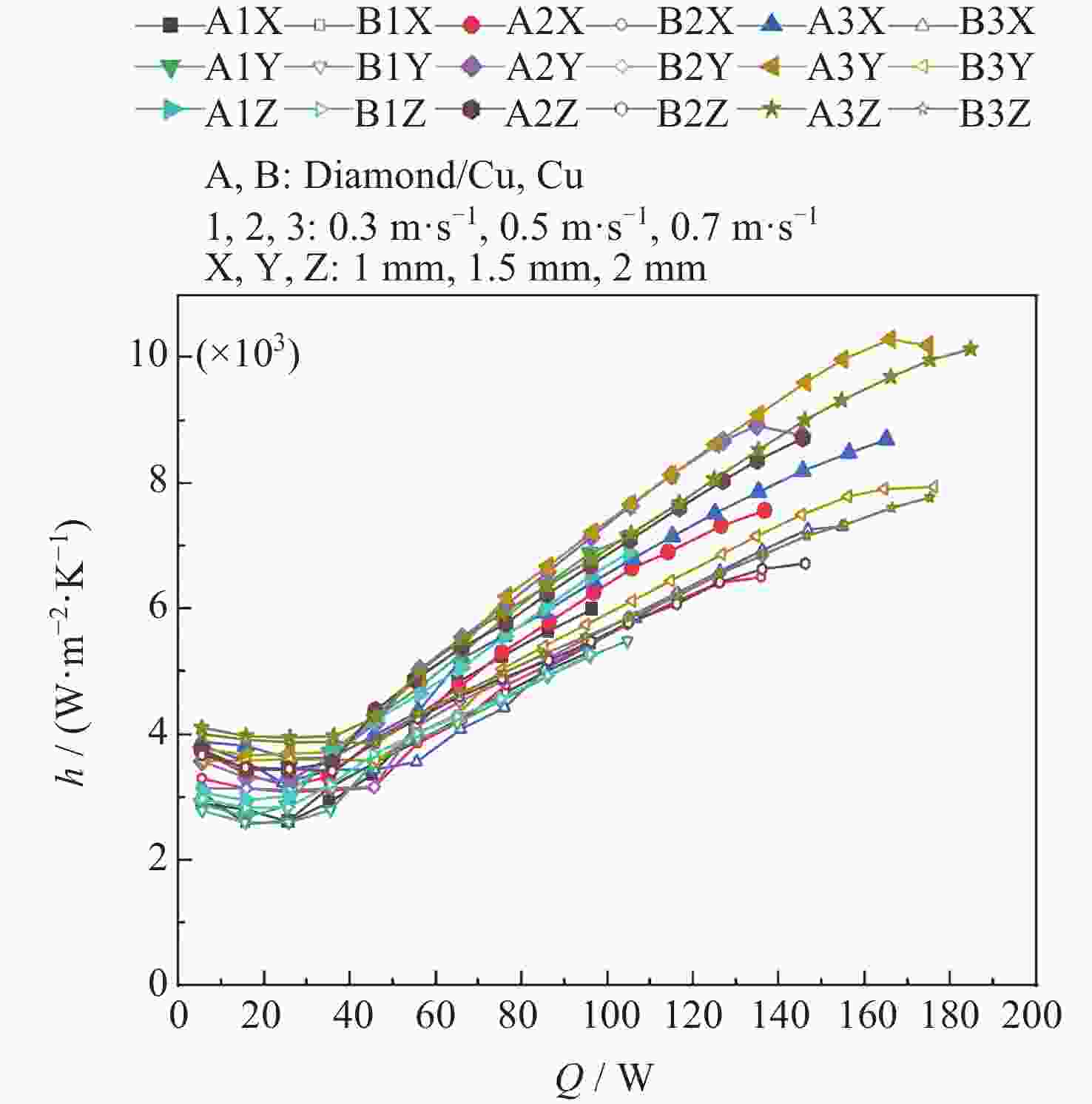

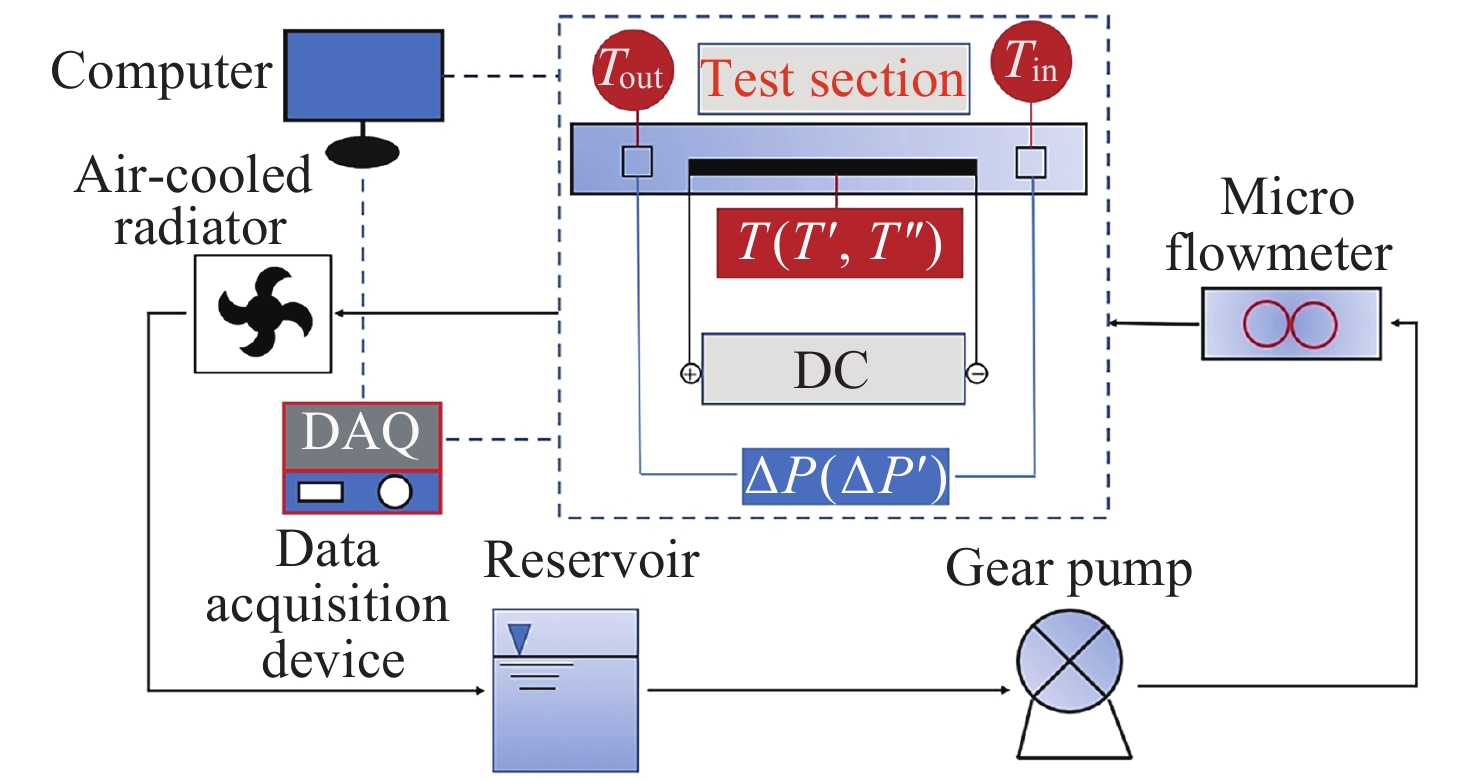

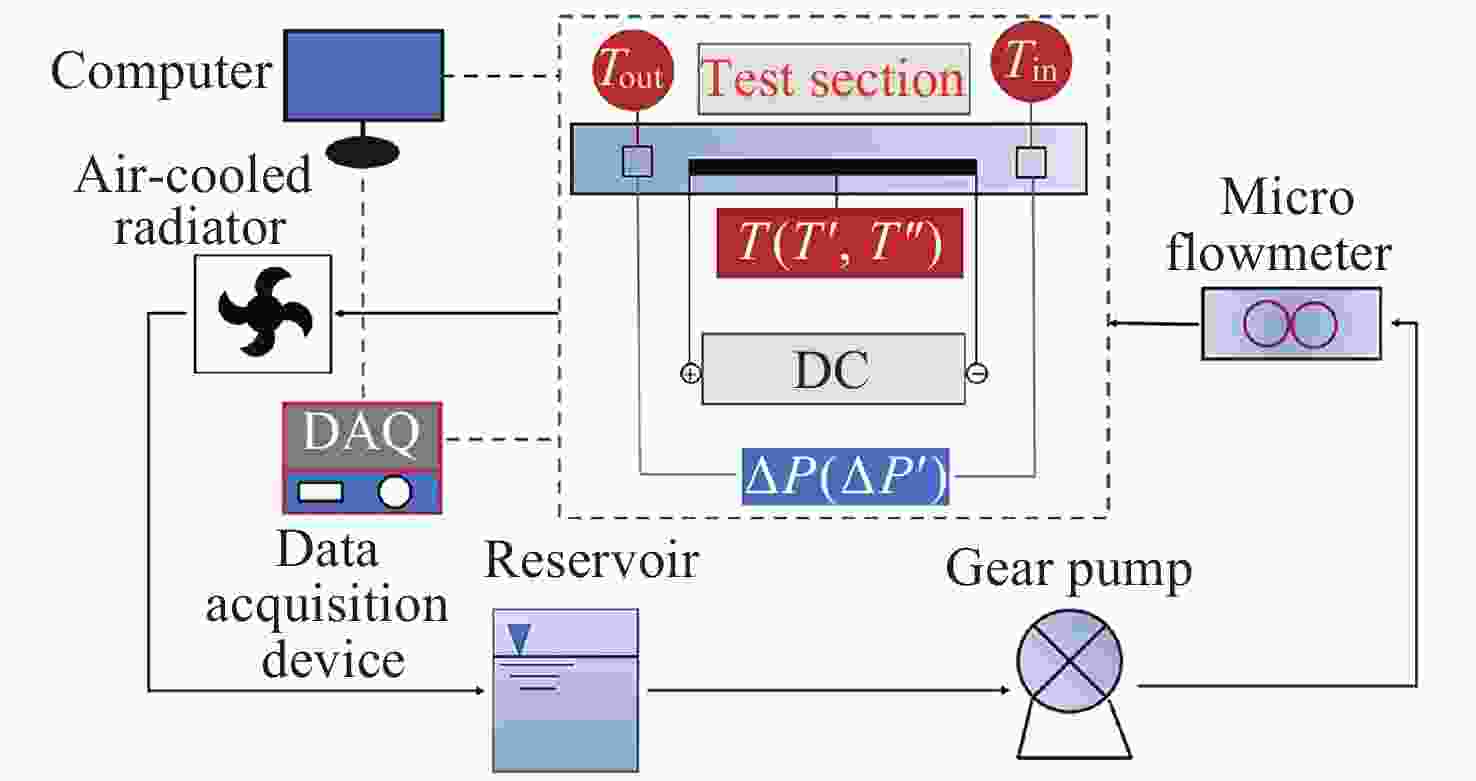

摘要: 随着航天器功能部件热流密度激增, 相关电子设备的寿命和可靠性面临着严峻的散热问题. 将微通道散热技术与高导热金刚石/铜复合材料相结合, 为解决航天器的散热难题提供了有效途径. 本文设计了一种分体式金刚石/铜微通道散热系统, 并与纯铜微通道系统对比. 以HFE-7100为工质, 研究了不同流速、不同肋高下两种微通道系统的传热特性. 当流速为0.7 m·s–1, 随着肋高的增加, 临界功率下金刚石/铜比纯铜微通道系统的芯片表面温度低12, 19, 19.6℃, 传热系数最大提升分别为27.8%, 30.1%, 28.1%. 两种微通道系统的压差在对流段几乎相同, 进入核态沸腾后, 金刚石/铜微通道系统压差整体略高, 最大增加了11.8%.Abstract: With the development of aerospace technology, the intelligence level of spacecraft is increasing day by day. The increasing demand for chip computing power leads to a significant increase in its heat flux density, and the life and reliability of related electronic devices are facing severe heat dissipation challenges. The combination of microchannel heat dissipation technology and high thermal conductivity diamond/copper composites provides an effective way to solve the heat dissipation challenges of spacecraft. In view of the poor machinability of diamond/copper composites, a split diamond/copper composite microchannel heat dissipation system is designed in this paper and compared with a pure copper microchannel system. The heat transfer characteristics of the two microchannel systems at different flow rates (0.3, 0.5, 0.7 m·s–1) and rib heights (1, 1.5, 2 mm) were investigated using HFE-7100 as the heat transfer medium. When the flow rate is 0.7 m·s–1, the chip surface temperatures of diamond/copper microchannels at the critical power are lower than those of pure copper microchannels by 12℃, 19℃, and 19.6℃, respectively, with the increase of rib height. The heat transfer coefficients were maximally enhanced by 27.8%, 30.1%, and 28.1% at the three rib heights, respectively, showing the heat dissipation advantages of the diamond/copper composite microchannels. The better heat transfer performance of the diamond/copper composite microchannel system is mainly due to its higher thermal conductivity and surface roughness. The pressure drop between the inlet and outlet of the two microchannel systems is basically the same in the single-phase flow section, and the difference gradually becomes apparent when entering nucleate boiling. At critical power, the pressure drop of the diamond/copper microchannel system is slightly higher than that of the pure copper microchannel system, with a maximum increase of 11.8%. The reason for the higher pressure drop in the diamond/copper microchannel system is that the turbulence level of the working fluid is higher in the diamond/copper microchannel system.

-

Key words:

- Diamond/copper composites /

- Microchannels /

- Phase transition heating

-

表 1 试验段材料主要尺寸

Table 1. Main materials dimensions of the test section

名称 代号 尺寸/mm 微通道铜肋板 H1×H2 45×61 微通道尺寸 L4×L1×L5 1×24×(1, 1.5, 2) 肋尺寸 L3×L1×L5 1×24×(1, 1.5, 2) 金刚石/铜散热片 ― 30×40×3 表 2 实验使用材料的主要物性

Table 2. Main physical properties of experimental materials

名称 物性名称 物性值 HFE-7100 沸点/℃ 61 密度/(kg·m–3) 1520 比热容/(J·kg–1·K–1) 1183 运动学黏度/(mm2·s–1) 0.38 金刚石/铜 热导率/(W·m–1·K–1) 700 密度/(kg·m–3) 5850 比热容/(J·kg–1·K –1) 434.5 表面粗糙度 Ra1.6 铜 热导率/(W·m–1·K–1) 400 密度/(kg·m–3) 8960 比热容/(J·kg–1·K–1) 390 表 3 实验设备主要参数及换热系数影响因素的相对误差

Table 3. Main parameters of the experimental equipment and relative error of factors affecting heat transfer coefficient

名称 测量范围 相对误差/(%) T1型热电偶 (直径0.08 mm) –200~200℃ ±0.34 T2型热电偶 (直径1 mm) –200~250℃ ±0.42 压差变送器 0~10 kPa ±3.3 直流电源电压 0~300 V ±0.65 直流电源电流 0~5 A 2.2 热效率计算误差 ― 11.7 T–Tin ― 3.6 流道换热面积 ― 0.5 表 4 9种工况下的两种微通道芯片表面的最大温差 (单位: ℃)

Table 4. Maximum temperature difference between two microchannel chip surfaces under 9 operating conditions (Unit: ℃)

肋高/ mm 流速/ (m·s–1) 0.3 0.5 0.7 1 8.3 10.7 12 1.5 16.8 18.4 19 2 13.4 19.3 19.6 -

[1] BELHARDJ S, MIMOUNI S, SAIDANE A, et al. Using microchannels to cool microprocessors: a transmission-line-matrix study[J]. Microelectronics Journal, 2003, 34(4): 247-253 doi: 10.1016/S0026-2692(03)00004-1 [2] TUCKERMAN D B, PEASE R F W. High-performance heat sinking for VLSI[J]. IEEE Electron Device Letters, 1981, 2(5): 126-129 doi: 10.1109/EDL.1981.25367 [3] BLOSCHOCK K P, BAR-COHEN A. Advanced thermal management technologies for defense electronics[C]//Proceedings of SPIE 8405, Defense Transformation and Net-Centric Systems. Baltimore: SPIE, 2012 [4] YU X G, XU K, MIAO J Y, et al. Design and on-board validation of pumped two-phase fluid loop for high heat flux removal[J]. Journal of Astronautics, 2017, 38(2): 192-197 [5] ALAM T, LI W M, CHANG W, et al. Favourably regulating two-phase flow regime of flow boiling HFE-7100 in microchannels using silicon nanowires[J]. Scientific Reports, 2021, 11(1): 11131 doi: 10.1038/s41598-021-89466-z [6] WANG H T, CHEN Z H, GAO J G. Influence of geometric parameters on flow and heat transfer performance of micro-channel heat sinks[J]. Applied Thermal Engineering, 2016, 107: 870-879 doi: 10.1016/j.applthermaleng.2016.07.039 [7] JING D L, HE L. Numerical studies on the hydraulic and thermal performances of microchannels with different cross-sectional shapes[J]. International Journal of Heat and Mass Transfer, 2019, 143: 118604 doi: 10.1016/j.ijheatmasstransfer.2019.118604 [8] QU W L, MALA G M, LI D Q. Pressure-driven water flows in trapezoidal silicon microchannels[J]. International Journal of Heat and Mass Transfer, 2000, 43(3): 353-364 doi: 10.1016/S0017-9310(99)00148-9 [9] HUNG T C, YAN W M, WANG X D, et al. Optimal design of geometric parameters of double-layered microchannel heat sinks[J]. International Journal of Heat and Mass Transfer, 2012, 55(11/12): 3262-3272 [10] BOTELER L, JANKOWSKI N, MCCLUSKEY P, et al. Numerical investigation and sensitivity analysis of manifold microchannel coolers[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7698-7708 [11] DE LOSIER C R, SUBRAMANIAN S, PONYAVIN V, et al. The parametric study of an innovative offset strip-fin heat exchanger[J]. Journal of Heat Transfer, 2007, 129(10): 1453-1458 doi: 10.1115/1.2755068 [12] LEE P S, GARIMELLA S V. Saturated flow boiling heat transfer and pressure drop in silicon microchannel arrays[J]. International Journal of Heat and Mass Transfer, 2008, 51(3/4): 789-806 [13] TRAN N, ZHANG C P, DANG T, et al. Numerical and experimental studies on pressure drop and performance index of an aluminum microchannel heat sink[C]//Proceedings of the 2012 International Symposium on Computer, Consumer and Control. Taichung, China: IEEE, 2012 [14] SINGH R, AKBARZADEH A, MOCHIZUKI M, et al. Thermal characterization of copper microchannel heat sink for power electronics cooling[J]. Journal of Thermophysics and Heat Transfer, 2009, 23(2): 371-380 doi: 10.2514/1.40033 [15] MOLINA J M, NARCISO J, WEBER L, et al. Thermal conductivity of Al–SiC composites with monomodal and bimodal particle size distribution[J]. Materials Science and Engineering: A, 2008, 480(1/2): 483-488 [16] ZWEBEN C. Advanced materials for optoelectronic packaging[J]. Semiconductor International, 2002, 25(10): S5-S6,S8 [17] BAI G Z, ZHANG Y J, DAI J J, et al. Tunable coefficient of thermal expansion of Cu-B/diamond composites prepared by gas pressure infiltration[J]. Journal of Alloys and Compounds, 2019, 794: 473-481 doi: 10.1016/j.jallcom.2019.04.252 [18] JIA J H, BAI S X, XIONG D G, et al. Effect of tungsten based coating characteristics on microstructure and thermal conductivity of diamond/Cu composites prepared by pressueless infiltration[J]. Ceramics International, 2019, 45(8): 10810-10818 doi: 10.1016/j.ceramint.2019.02.156 [19] ABYZOV A M, KIDALOV S V, SHAKHOV F M. High thermal conductivity composites consisting of diamond filler with tungsten coating and copper (silver) matrix[J]. Journal of Materials Science, 2011, 46(5): 1424-1438 doi: 10.1007/s10853-010-4938-x [20] MAŃKOWSKI P, DOMINIAK A, DOMAŃSKI R, et al. Thermal conductivity enhancement of copper-diamond composites by sintering with chromium additive[J]. Journal of Thermal Analysis and Calorimetry, 2014, 116(2): 881-885 doi: 10.1007/s10973-013-3604-3 [21] HUANG S H, GUO H, ZHANG Z, et al. Comparative study on the properties and microscopic mechanism of Ti coating and W coating diamond-copper composites[J]. Materials Research Express, 2020, 7(7): 076517 doi: 10.1088/2053-1591/aba55d [22] HU H B, KONG J. Improved thermal performance of diamond-copper composites with boron carbide coating[J]. Journal of Materials Engineering and Performance, 2014, 23(2): 651-657 doi: 10.1007/s11665-013-0780-z [23] LIU R X, LUO G Q, LI Y, et al. Microstructure and thermal properties of diamond/copper composites with Mo2C in-situ nano-coating[J]. Surface and Coatings Technology, 2019, 360: 376-381 doi: 10.1016/j.surfcoat.2018.12.116 [24] HASSELMAN D P H, JOHNSON L F. Effective thermal conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composite Materials, 1987, 21(6): 508-515 doi: 10.1177/002199838702100602 [25] YANG L, SUN L, BAI W W, et al. Thermal conductivity of Cu-Ti/diamond composites via spark plasma sintering[J]. Diamond and Related Materials, 2019, 94: 37-42 doi: 10.1016/j.diamond.2019.02.014 [26] WANG L H, LI J W, BAI G Z, et al. Interfacial structure evolution and thermal conductivity of Cu-Zr/diamond composites prepared by gas pressure infiltration[J]. Journal of Alloys and Compounds, 2019, 781: 800-809 doi: 10.1016/j.jallcom.2018.12.053 [27] SANG J Q, YUAN Y, YANG W L, et al. Exploring the underlying causes of optimizing thermal conductivity of copper/diamond composites by interface thickness[J]. Journal of Alloys and Compounds, 2022, 891: 161777 doi: 10.1016/j.jallcom.2021.161777 [28] MOFFAT R J. Describing the uncertainties in experimental results[J]. Experimental Thermal and Fluid Science, 1988, 1(1): 3-17 doi: 10.1016/0894-1777(88)90043-X -

-

冯小明 男, 1994年6月出生于陕西渭南, 现为西安交通大学化学工程与技术学院硕士研究生, 研究方向为金刚石/铜复合材料及微通道相变散热. E-mail:

冯小明 男, 1994年6月出生于陕西渭南, 现为西安交通大学化学工程与技术学院硕士研究生, 研究方向为金刚石/铜复合材料及微通道相变散热. E-mail:

下载:

下载: